Iron-based catalyst for pentadiene polymerization and method for preparing polypentadiene

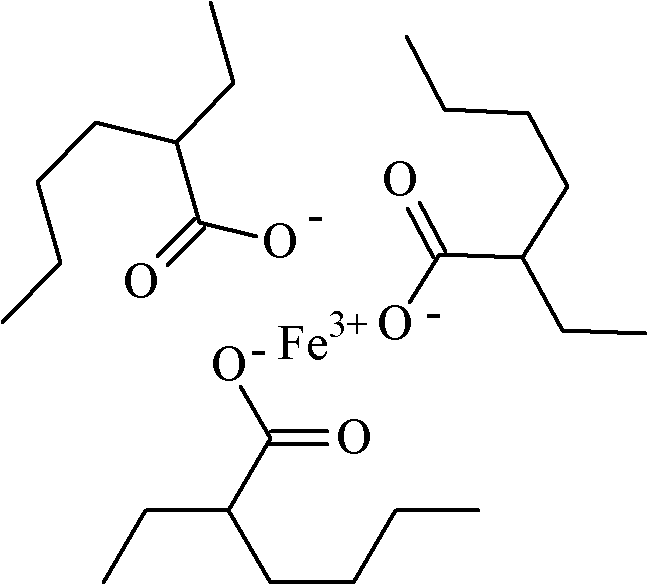

A piperylene and catalyst technology, which is applied in the field of preparation of iron-based catalysts and polypiperylene, which can solve the problems of low catalyst activity, uncontrollable polypiperylene configuration, and increased synthesis costs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] The present invention also provides a preparation method of polypiperylene, a) dissolving piperylene monomer in an organic solvent to obtain piperylene solution; b) dissolving iron isooctanoate, alkylaluminum compound, The electron donor is mixed with the piperylene solution at a molar ratio of 1:5 to 20:1 to 5 to obtain a reaction solution; the electron donor is a phosphite compound; c) the reaction solution is mixed at 0 to Heating at 70°C, the piperylene monomer undergoes a polymerization reaction, and after the reaction is terminated, the product is condensed, and polypiperylene is obtained after drying.

[0038] The polypiperylene provided by the present invention, that is, polypiperylene, uses the iron-based catalyst provided by the present invention, preferably in anhydrous and oxygen-free, under nitrogen protection, mixes the organic solvent with the piperylene monomer, and configures The concentration of the monomer is preferably 0.08-0.2 g / mL of the piperylene...

Embodiment 1

[0042] Add 7mL of hexane, 3mL of piperylene monomer, and hexane solution of iron isooctanoate to the catalyst reaction flask protected by anhydrous and oxygen-free nitrogen. The molar ratio of piperylene to Fe is 1500, diethyl phosphite Hexane solution of ester, [P] / [Fe]=2 and hexane solution of triisobutylaluminum, [Al] / [Fe]=10, at 50°C, after 4 hours of polymerization reaction, containing 1% 2,6-di-tert-butyl-p-cresol in ethanol to terminate. Polyisoprene was coagulated with excess ethanol. The yield of polymer was 96.4 wt%.

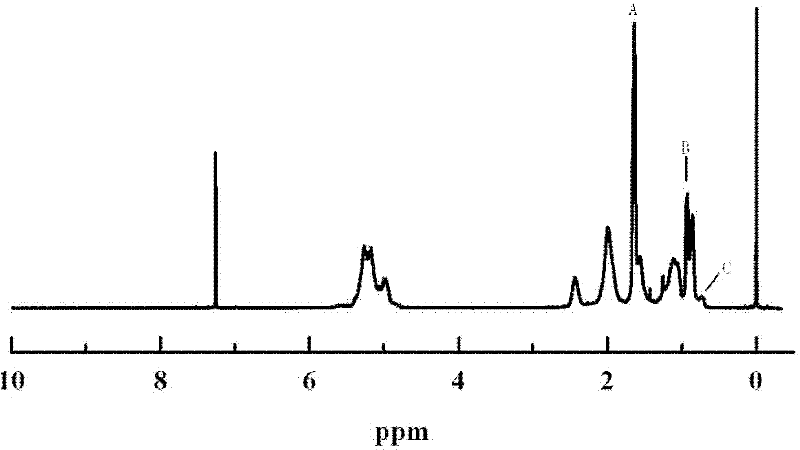

[0043] Polymer 400M prepared by embodiment 1 1 H spectrum characterizes the microstructure, such as figure 1 As shown, the 1,4-structure content in the polymer molecule is 35.9%, the 1,2-structure content is 61.0%, and the 3,4-structure content is 3.1%. The model for molecular weight and molecular weight distribution is Waters 515 Gel Permeation Chromatography instrument, THF was used as the mobile phase, and polystyrene was used as the standard sa...

Embodiment 2

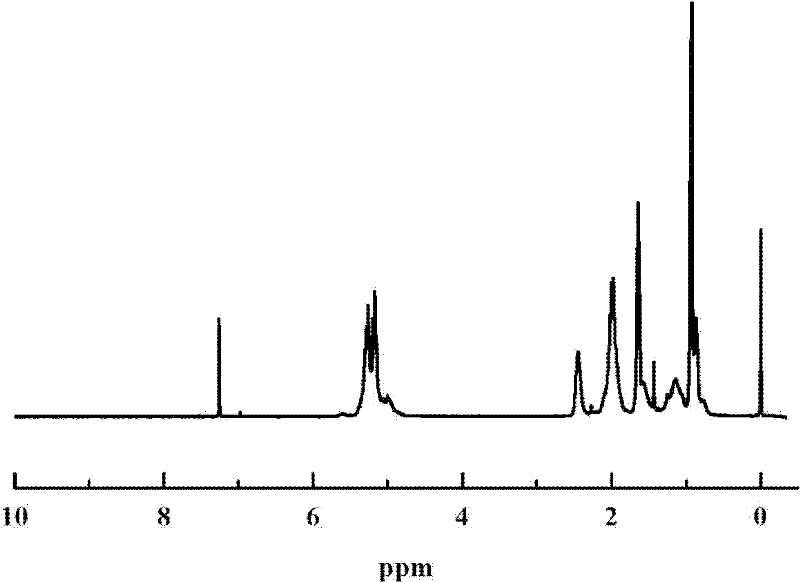

[0045] As described in Example 1, other conditions are exactly the same, only the molar ratio of triisobutylaluminum to Fe is changed to 5, the yield of the polymer is 3.2wt%, the polymer 1,4-structure content is 32.6%, 1 , 2-structure content is 61.4%, 3,4-structure content is 6.0%, number average molecular weight (Mn) is 2.15×10 5 , The molecular weight distribution index is 3.2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com