Tray bubble type biomass continuous hydrogen production method and device

A biomass and tray technology, applied in biochemical equipment and methods, gas production bioreactors, photobioreactors, etc., can solve the problems of light and dark fermentation, uniform feed liquid temperature and continuous hydrogen production, and influence on hydrogen production. Competitiveness with fossil energy, constraints on the large-scale application of biomass hydrogen production, etc., to achieve uniform distribution, promote full contact, and maintain a stable pH value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

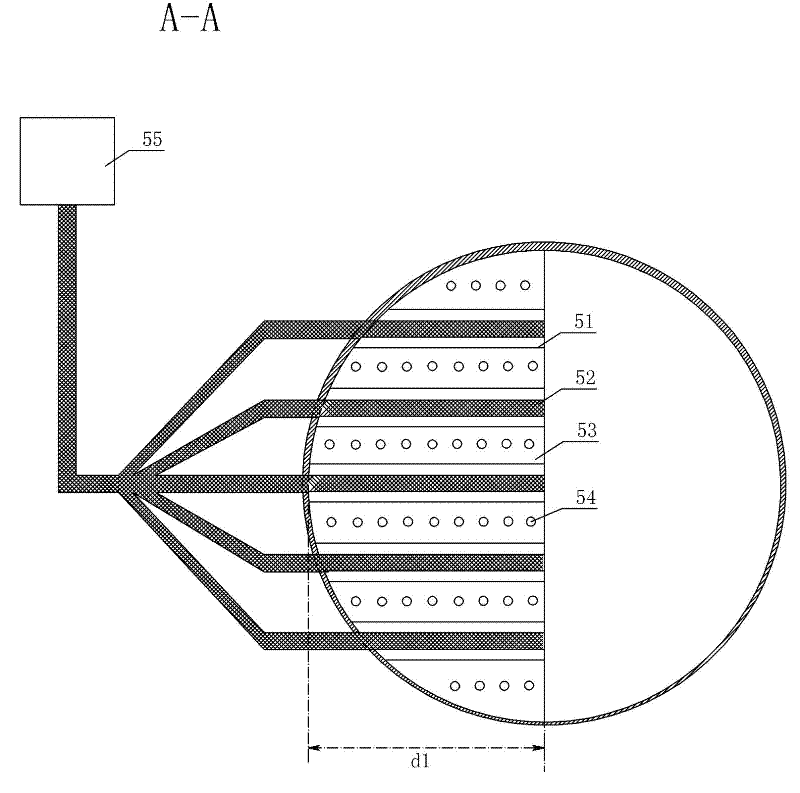

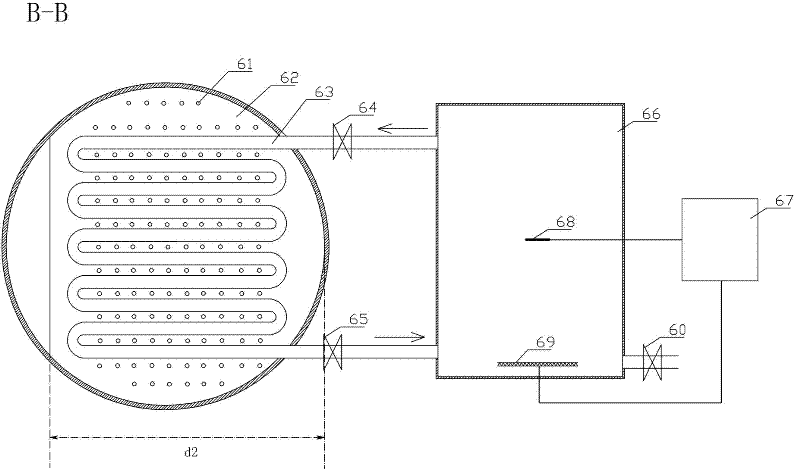

[0032] A method for continuous photosynthetic hydrogen production of tray bubble biomass, which is to alternately pass the material containing photosynthetic organisms through side optical fiber trays and U-shaped heat exchangers under the condition of a built-in light source or using optical fibers to introduce sunlight into a closed volume Trays, and under the action of reflux hydrogen bubbles, hydrogen is produced continuously through suspension heat exchange and light and dark fermentation.

Embodiment 2

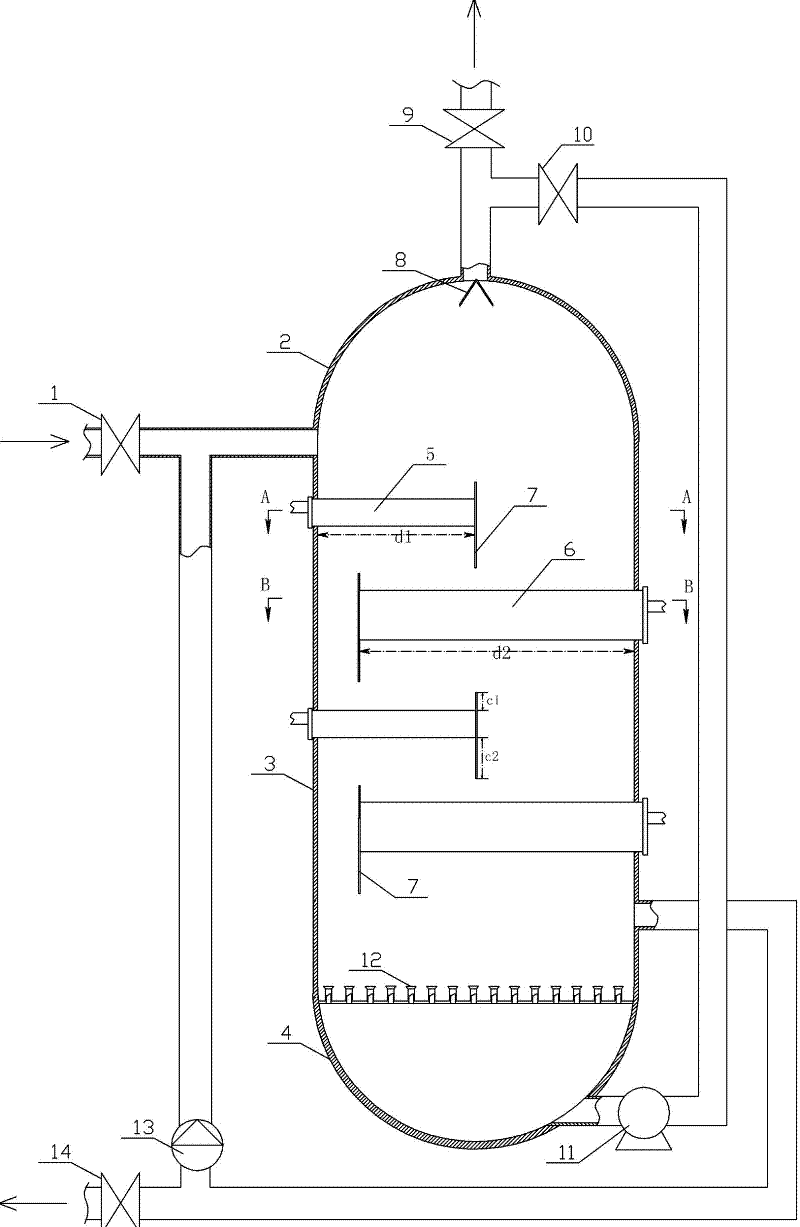

[0034] like figure 1 The schematic diagram of the structure of the tray bubble type biomass continuous hydrogen production device shown, the device consists of a feed valve 1, a hemispherical gas storage chamber 2, a tray type fermentation reaction tank 3, a bubble chamber 4, and a quartz-side optical fiber tray 5 , U-shaped heat exchanger tray 6, partition wall 7, gas-liquid separation partition 8, gas outlet valve 9, hydrogen return valve 10, blower 11, wind cap 12, sludge pump 13 and discharge valve 14, etc.

[0035] The hemispherical gas storage chamber 2, the tray type fermentation reaction tank 3 and the bubble chamber 4 are welded by 6mmQ235 steel plate, and the inner wall of the steel plate is painted with epoxy asphalt paint to avoid being corroded by material liquid and gas. The outside of the steel plate is an insulation structure, which is composed of an inner insulation layer and an outer protective layer, and the insulation layer is made of 150mm thick foam board...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com