Electroosmotic dehydration method and device for material containing water

A dewatering device and electro-osmosis technology, applied in the drying of solid materials, dewatering/drying/concentrating sludge treatment, drying solid materials without heating, etc. , easy to set and move, stable high-dry dehydration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

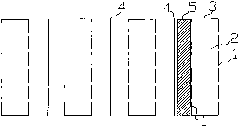

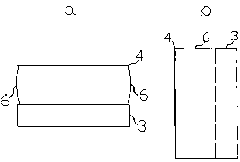

[0027] This example is an example of electroosmotic dehydration of shochu lees and food residues. Such as Figure 7 In the electroosmotic dehydration device shown, the distiller's grains obtained by pressing and filtering with a plate and frame filter press are electroosmotically dehydrated using an anode coated with a precious metal to obtain a dehydrated cake. The rotary plate under the electrode adopts such as image 3 The structure of a plate shown in c. The maximum distance between cathode and anode is 25mm, and the voltage is 20V.

Embodiment 2

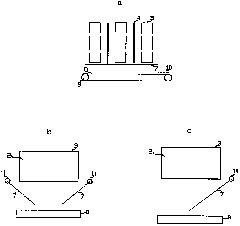

[0029] This example is an embodiment of electroosmotic dehydration of sewage plant sludge, using such as Figure 7 The electroosmotic dehydration device shown. After the sludge from the sewage treatment plant is dehydrated to 82% by a belt filter press, it is pushed into the water-containing material storage tank by a screw conveyor. Then use 0.02MPa compressed air to press it out and install it into the electrode unit. The material storage tank is lowered to make contact with the electrode during the loading process, and raised to disengage it from the electrode during other processes. The maximum distance between cathode and anode is 20mm, and the voltage is 15V. The rotary plate under the electrode adopts such as image 3 The structure of the two plates shown in b. The moving mechanism at both ends of the electrode in the horizontal direction adopts Image 6 b and Image 6 The structure of d. The inclined connecting rod between the electrodes is made of electrically ...

Embodiment 3

[0031] The embodiment of electroosmotic dehydration of sewage plant sludge is basically the same as that of embodiment 2. The difference is that the rotating plate under the electrode adopts image 3 The structure shown in c. The moving mechanism at both ends of the electrode in the horizontal direction adopts Image 6 c and Image 6 The structure shown in e. The inclined connecting rod between the electrodes is made of stainless steel, the rotary shaft is made of metal material, and the chute is made of polyethylene material. The compressed air of 0.08MPa presses out the sludge and puts it into the electrode unit.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com