Immobilized microspheres for remediation of petroleum contaminated soil, preparation method thereof and application thereof

A technology for soil remediation and oil pollution, applied in the restoration of contaminated soil, fixed on/in organic carriers, etc., can solve the problems of slow development of microbial preparation technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

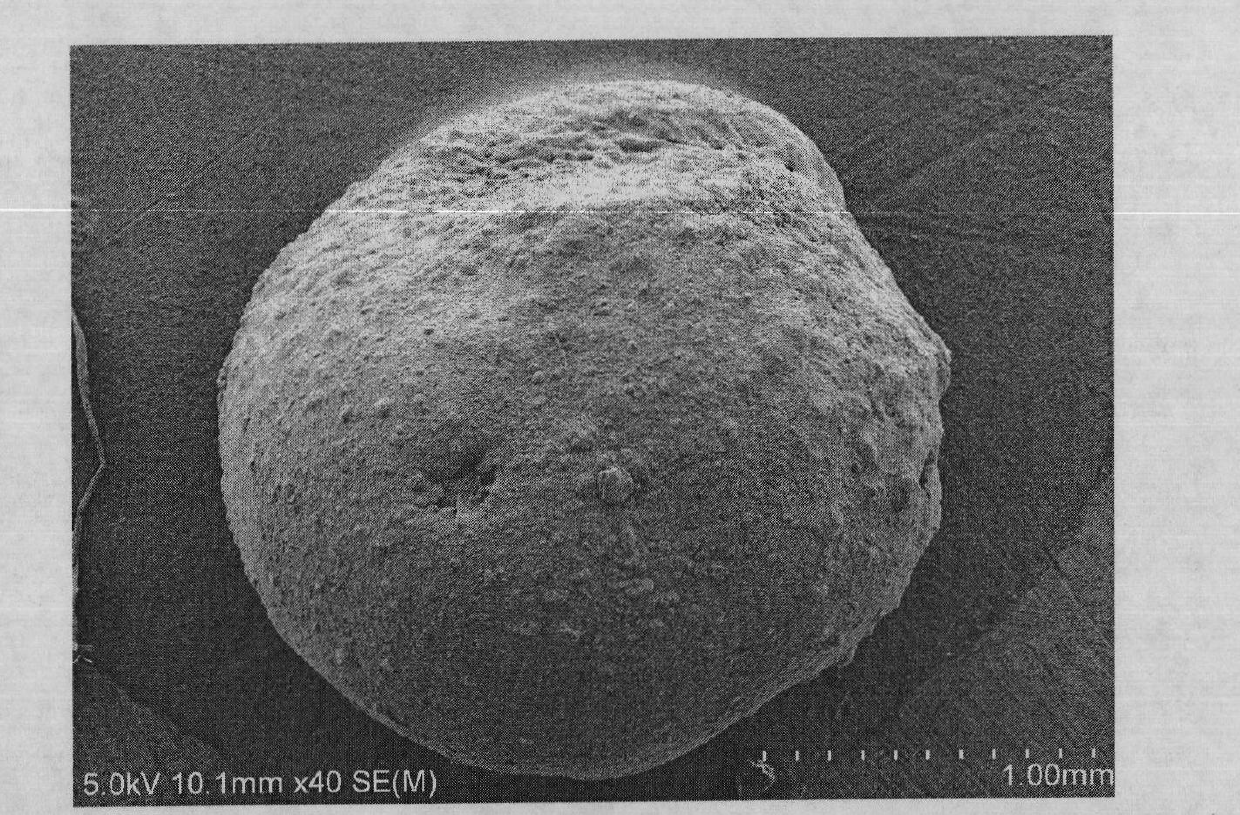

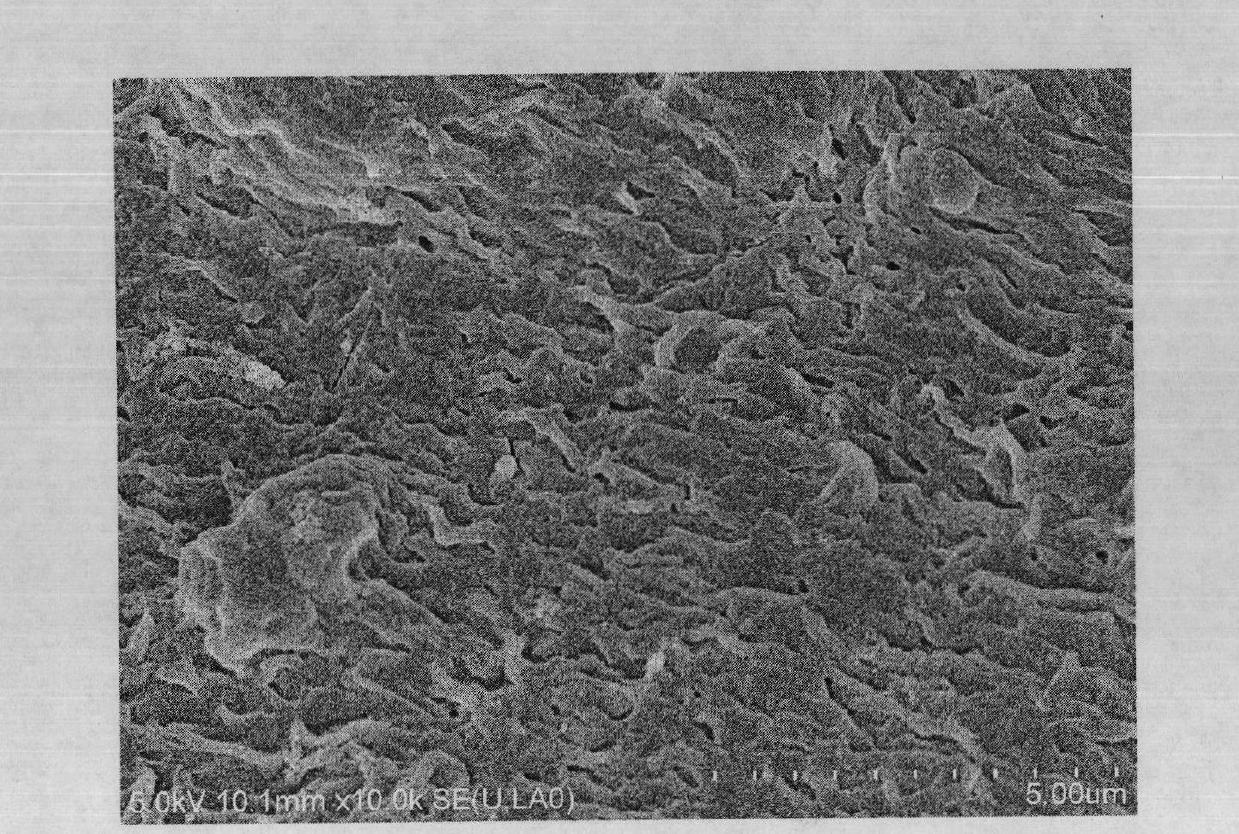

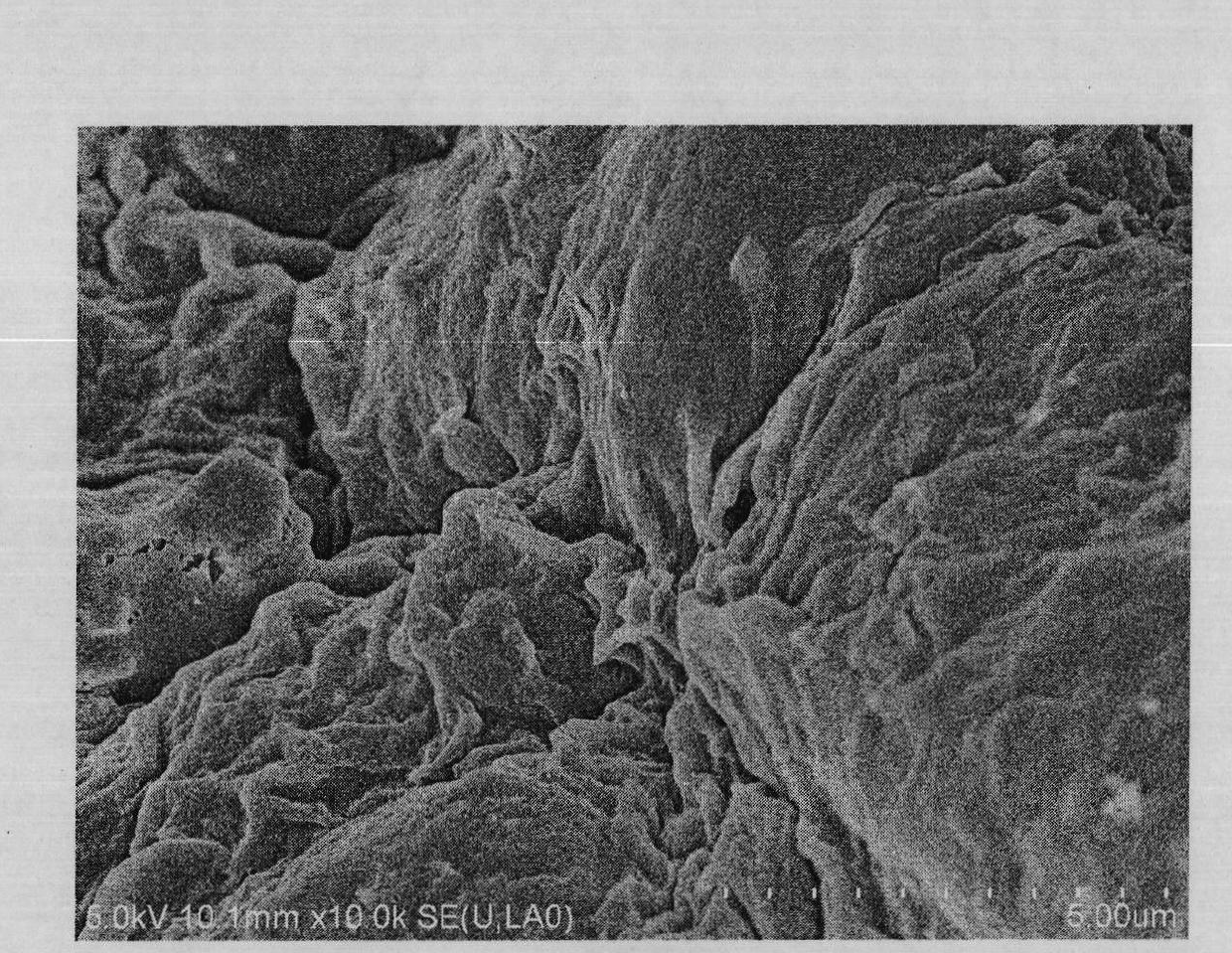

Image

Examples

preparation example Construction

[0043] (1) Preparation of bacterial suspension:

[0044] Preparation of medium A:

[0045] Enrichment medium: used to inoculate petroleum hydrocarbon-degrading bacteria, prepare LB liquid medium according to conventional methods of microbiology, and use conventional methods for high-temperature sterilization. It can be sterilized at 121°C for 30 minutes, cooled to room temperature, and enriched Medium.

[0046] Proliferation medium: used to provide nutrients for petroleum hydrocarbon degrading bacteria, including glucose 20g / L, yeast extract 3g / L, peptone 2g / L, NH 4 NO 3 1g / L MgSO 4 ·7H 2 O 0.2g / L, KCl 0.2g / L, pH=7.8, use conventional methods for high-temperature sterilization, can be sterilized at 115°C for 20min, cool down for later use.

[0047] B enrichment culture:

[0048] Rinse the bacteria liquid from the slant culture medium of preserved petroleum hydrocarbon-degrading bacteria into common LB liquid culture medium, and obtain seed liquid after 12 hours of shake...

Embodiment 1

[0081] (1) Bacterial suspension preparation:

[0082] Preparation of A medium: (the medium of the following examples all adopts the medium prepared in Example 1, so the step (1) A of the following examples is omitted, and the description starts from step (1) B)

[0083] Enrichment medium: prepare a few milliliters of LB liquid medium according to conventional methods of microbiology: tryptone 10g / L, yeast extract 5g / L, sodium chloride 5g / L, pH=7.0.

[0084] Divide the above-mentioned enriched culture medium into several 1000ml Erlenmeyer flasks, the volume of each flask is 4 / 5 of the volume, put it into a high-temperature sterilization device, sterilize at 121°C for 30min, and cool to room temperature.

[0085] Proliferation medium (prepared according to conventional biological methods): glucose 20g / L, yeast extract 3g / L, peptone 2g / L, NH 4 NO 3 1g / L, MgSO 4 ·7H 2 O 0.2g / L, KCl 0.2g / L, pH=7.8. Sterilize at 115°C for 20min, cool for later use.

[0086] B enrichment cultur...

Embodiment 2

[0099] (1) Bacterial suspension preparation:

[0100] B enrichment culture:

[0101] In an aseptic operating bench, inoculate the Paracoccus sp.D17 strain in the enrichment medium at an inoculation amount of 5%; after completion, place it in a constant temperature culture shaker, adjust the shaker speed to 150rpm, and cultivate at 25°C for 48h; The bacterial liquid was collected and centrifuged at 4000 rpm for 10 minutes to obtain wet bacterial cells, which were stored at 4°C.

[0102] C bacteria suspension preparation:

[0103] 4g of wet bacteria was mixed evenly with 10ml of proliferation medium to prepare a bacterial suspension, which was stored at 4°C for later use.

[0104] (2) Preparation of sodium alginate-attapulgite gel:

[0105] Mix 3.5g of sodium alginate and 2.0g of attapulgite evenly, put in 90ml of deionized water, sterilize at 121°C for 30min, and then place it in a 60°C water bath to keep warm.

[0106] (3) Bacterial suspension dosing:

[0107] Take 90ml o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com