Rice carding harvester

A harvester and rice technology, applied in threshing equipment, agricultural machinery and implements, applications, etc., can solve the problems of difficult paddy field operations, large grain loss, and difficult transportation, and achieve the elimination of cleaning links, less loss, and light weight Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

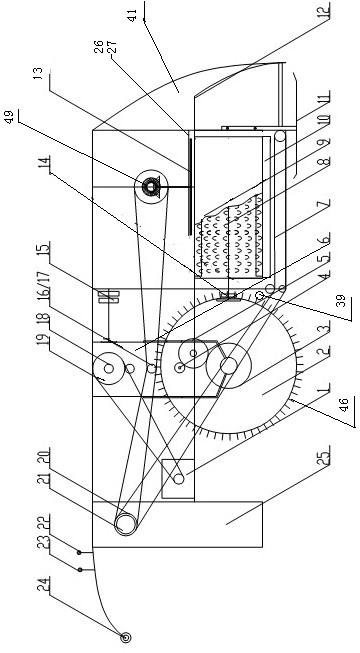

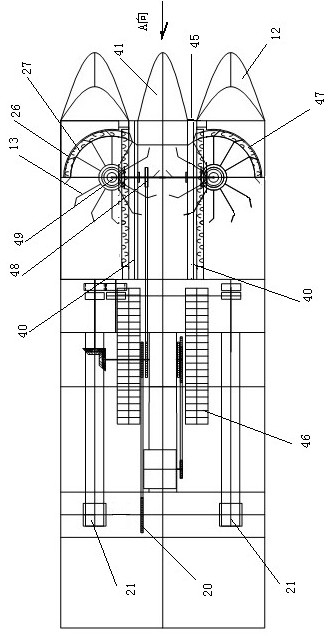

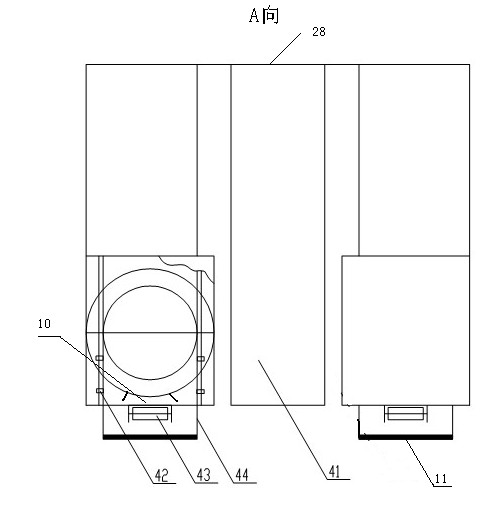

[0034] Such as figure 1 , figure 2 , image 3 As shown, the first off-type rice harvester of the present invention is mainly composed of a power machine 1, a gearbox 6, a belt drive, a threshing cylinder 8, a grain conveying belt 7, a rotating grain disc 13, a walking wheel 2, etc.; the power machine output pulley It is connected with the driven wheel on the gearbox with a transmission belt, and the transmission gear shafts in the gearbox 6 are connected through the clutch 19. The transmission gear shafts (from top to bottom according to the transmission sequence) are the first, second, third, and fourth Gear shaft, the pinion gear of the first gear shaft meshes with the large gear of the second gear shaft, the small gear of the second gear shaft meshes with the large gear of the third gear shaft, and the small gear of the third gear shaft meshes with the large gear of the fourth gear shaft (each shaft Different speeds are generated by the meshing of large and small gears, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com