Selective hydrogenation method for C2 fraction

A selectivity and fractionation technology, applied in hydrocarbons, chemical instruments and methods, purification/separation of hydrocarbons, etc., can solve problems such as large economic losses and difficulty in uniform loading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

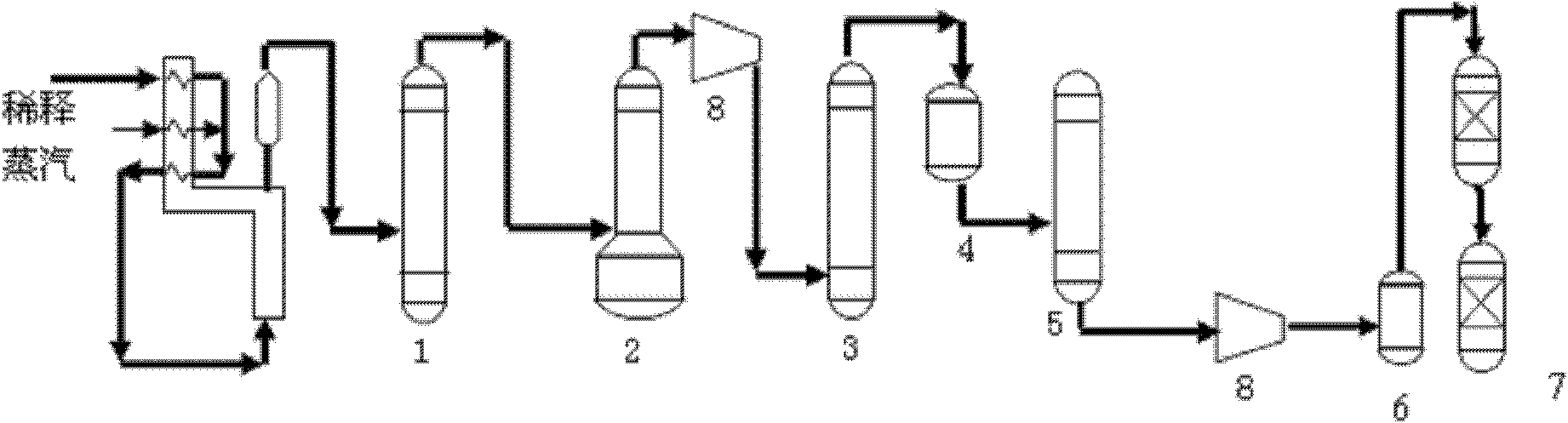

Method used

Image

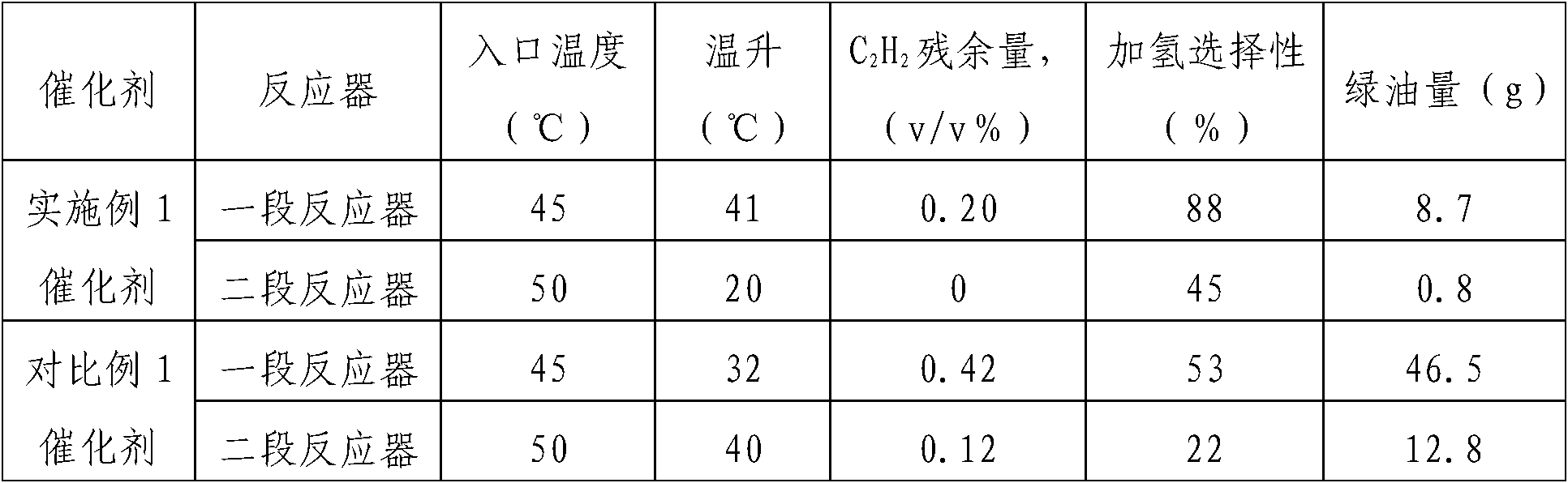

Examples

Embodiment 1

[0060] Catalyst preparation:

[0061] A. Functionalized polyvinyl chloride (PVC) / Al 2 o 3 preparation of

[0062] Weigh Φ4.5mm, length is 4.5mm, specific surface area is 15.m 2 / g, the pore volume is 0.25ml / g, the bulk density is 1.1g / cm 3 Columnar Al 2 o 3 Carrier 250g.

[0063] Dissolve 4.450g of PVC completely in 400mlTHF (tetrahydrofuran), immerse the above-mentioned carrier into the above-mentioned solution, let the PVC adsorb on Al after standing for 2h 2 o 3 Surface, dry. Get 205gPVC / Al 2 o 3 product.

[0064] Add 59.64g dicyandiamide and 2.0gNa 2 CO 3 ,, add 205g PVC / Al 2 o 3 Reflux for 1 h, cool to room temperature, wash with deionized water until neutral, and dry for later use. Get functionalized PVC / Al 2 o 3 .

[0065] B. (Pd-Ag)-polymer / Al 2 o 3 Precursor preparation

[0066] Weigh 0.165gPd(NO 3 ) 2 , 0.8gAgNO 3 , measure 0.5ml of nitric acid, prepare a mixed solution of 1200ml, weigh the prepared functionalized-PVC / Al 2 o 3 Precursor 255...

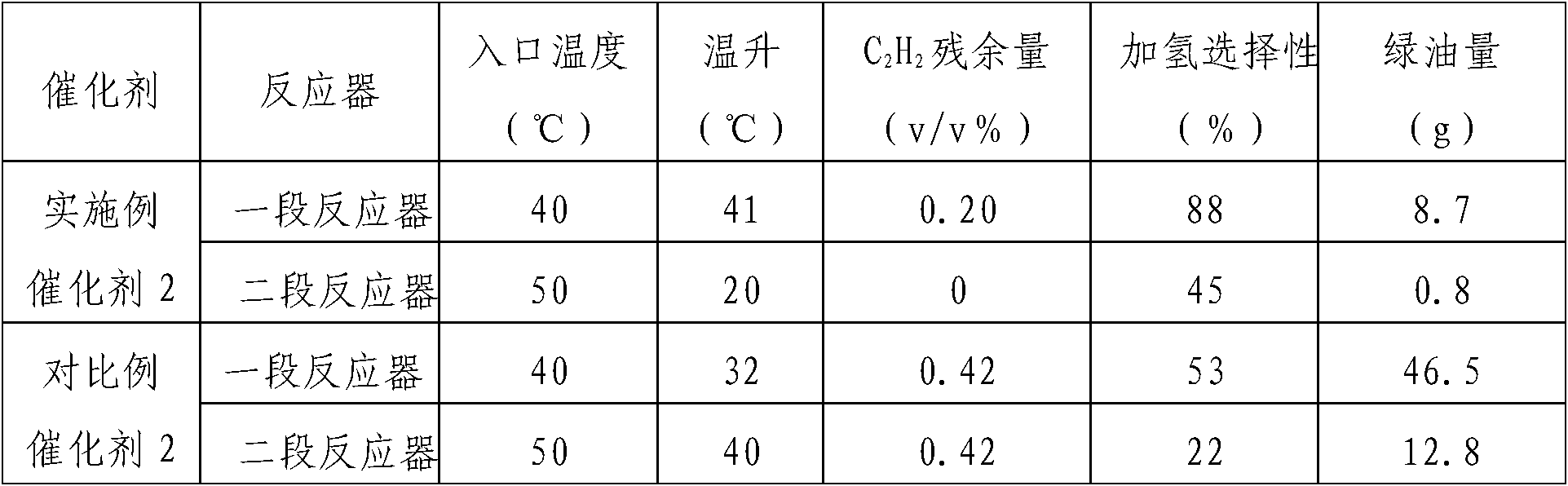

Embodiment 2

[0082] Catalyst preparation

[0083] A. Functionalized polystyrene acrylonitrile (SAN) / Al 2 o 3 preparation of

[0084] Weigh Φ2.5mm, the specific surface area is 50m 2 / g, the pore volume is 0.8ml / g, the bulk density is 0.65g / cm 3 spherical Al 2 o 3 Carrier 250g

[0085] Weigh 1.1g of SAN resin, dissolve it in 300ml of DMF (dimethylformamide) solvent, stir at room temperature to completely dissolve the SAN resin, add the above-mentioned weighed carrier in this solution, let it stand for 6 hours after fully stirring, separate Solvent post-drying yields SAN / Al 2 o 3 .

[0086] The above obtained SAN / Al 2 o 3 , added to 500ml deionized water, 28.8g ethylenediamine was added, refluxed for 4h, the product was taken out after cooling, washed until neutral, and dried to obtain functionalized-SAN / Al 2 o 3 .

[0087] B. (Pd-Ag)-SAN / Al 2 o 3 Precursor preparation

[0088] Weigh 0.47gPd(NO 3 ) 2 , 0.4gAgNO 3 , measure 0.5ml of nitric acid, prepare a mixed solution of...

Embodiment 3

[0105] Catalyst preparation

[0106] Weigh Φ4.5mm, length is 4.5mm, specific surface area is 25.m 2 / g, the pore volume is 0.35ml / g, the bulk density is 0.75g / cm 3 Columnar Al 2 o 3 Carrier 250g.

[0107] A, the preparation of functionalized chlorinated polyethylene (CPE)

[0108] Dissolve 8.0g of CPE completely in 400mlTHF, add 240g of dicyandiamide and 2.0g of Na 2 CO 3 ,, add CPE to reflux for 2 hours, cool to room temperature, wash with deionized water until neutral, and obtain functionalized CPE for future use.

[0109] B. (Pd-Ag)-polymer / Al 2 o 3 Precursor preparation

[0110] Weigh 0.22gPd(NO 3 ) 2 , 0.28gAgNO 3 , Measure 0.5ml of nitric acid, add it into the above functionalized CPE solution, and stir for 60min to obtain (Pd—Ag)—CPE.

[0111] Add 250g of the carrier into the mixed solution, stir well and let it stand for 4h, wash the above product with deionized water until neutral to obtain (Pd-Ag)-CPE / Al 2 o 3 Precursor.

[0112] C. Preparation of cat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com