High-purity germanium polycrystal preparation process and special equipment

A preparation process and high-purity technology, applied in the direction of polycrystalline material growth, single crystal growth, single crystal growth, etc., to achieve the effect of improving product purity, avoiding rupture loss, and improving purification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Aiming at the defects of the prior art, the invention provides a preparation process and special equipment capable of preparing high-purity germanium polycrystalline material.

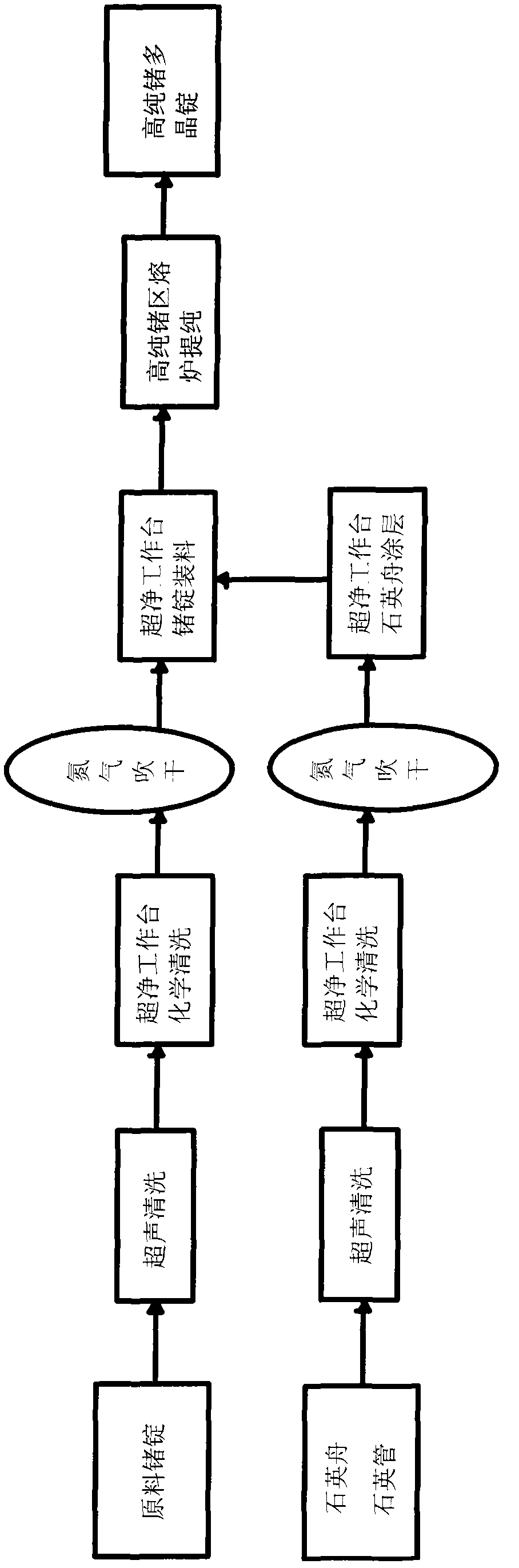

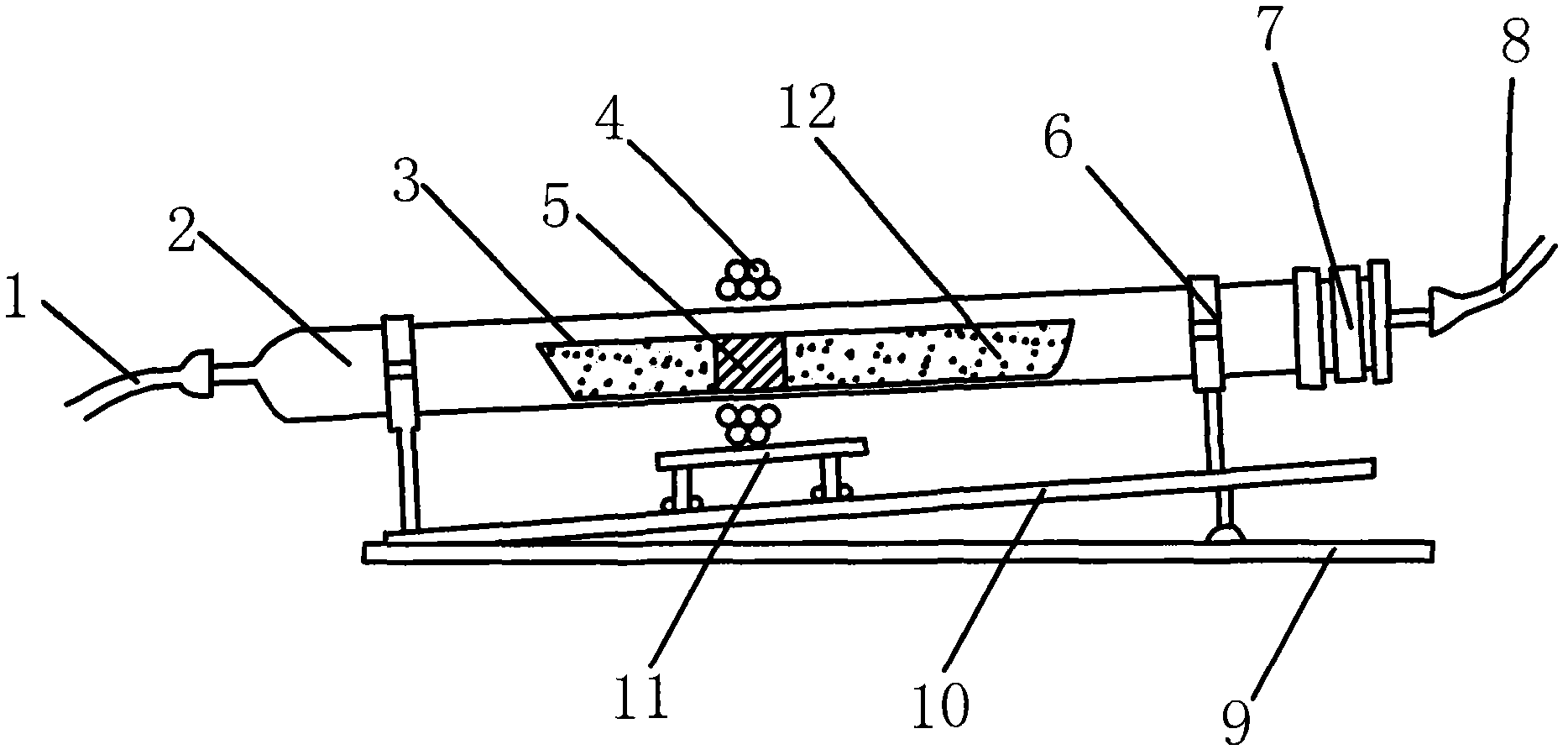

[0029] figure 1 Shown is the flow chart of the preparation process of germanium polycrystal of the present invention. The high-purity germanium polycrystal preparation process of the present invention includes two parts: cleaning of raw material germanium ingots and zone melting equipment, and zone melting purification.

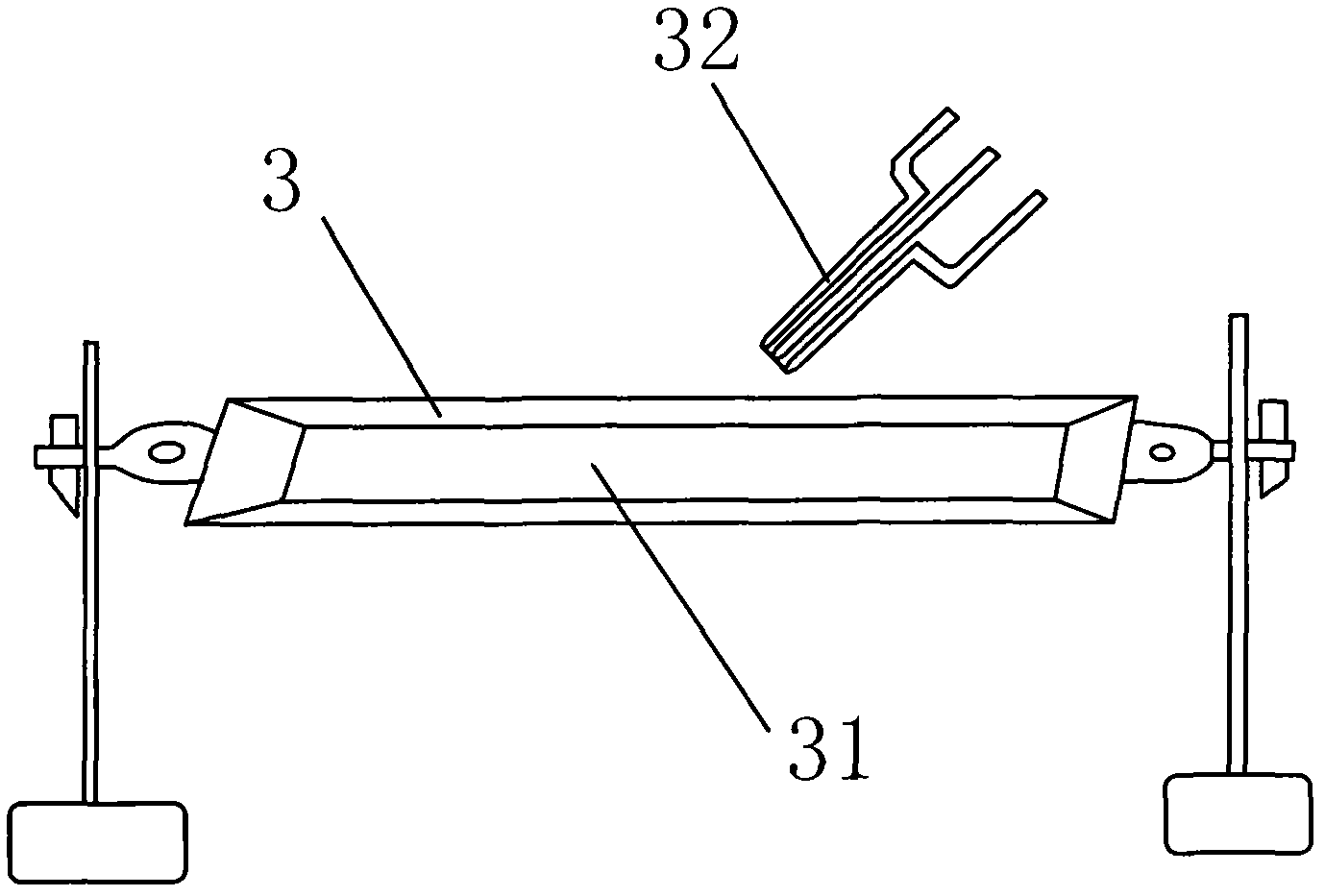

[0030] The cleaning of the raw material germanium ingots sequentially includes ultra-clean water cleaning of the ultrasonic cleaner, chemical cleaning of the ultra-clean workbench, and nitrogen blow-drying steps; the cleaning of the zone melting equipment sequentially includes ultra-clean water cleaning of the ultrasonic cleaner, ultra-clean work Chemical cleaning of benches, nitrogen blow-drying, and surface coating steps of zone melting equipment.

[0031] The purity of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com