Solid phase and liquid phase integrated methane fermenting device

The technology of solid-phase fermentation and fermentation tank is applied in the field of solid-liquid two-phase integrated biogas fermentation device, and achieves the effects of convenient operation, convenient feeding and slag discharge, and sufficient degradation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

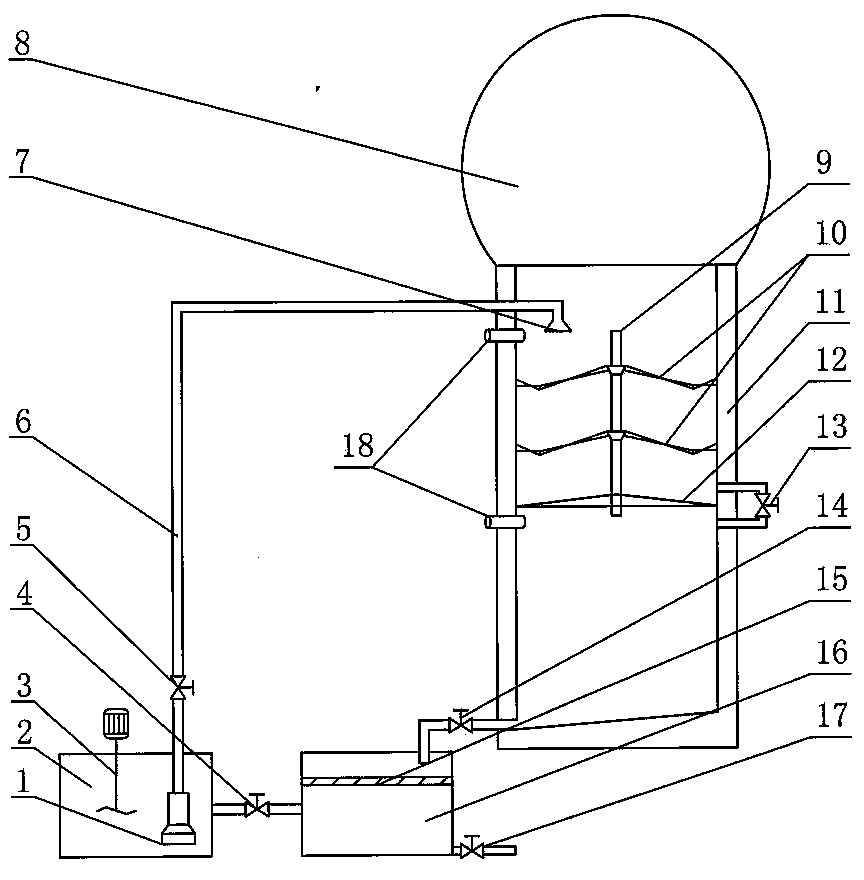

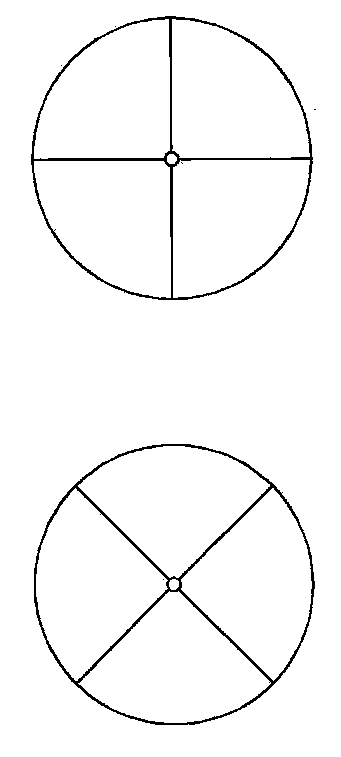

[0011] See figure 1 , the specific structure is as follows: an open feeding tank 2 and a liquid collecting tank 16 are set, and a stirring device 3 and a mud pump 1 are set in the feeding tank 2 . The upper end of the cylindrical fermenter 11 with an insulating layer is provided with an air storage air bag 8, and a nozzle 7 is arranged at the upper part of the fermenter 11, and the nozzle 7 is connected to the mud pump 1 through the feeding pipe 6 and the valve 5; The space is divided into an upper solid-phase fermentation area and a lower liquid-phase fermentation area; a double-layer shell-breaking cutting arm 10 is set in the solid-phase fermentation area; see figure 2 , The double-layer shell breaking cutting arm 10 is made of a "ten" shaped cutting board, and the upper and lower shell breaking cutting arms 10 are installed at a dislocation of 45 degrees. A connecting pipe 9 for biogas slurry and biogas is arranged in the fermenter 11; A sight glass 18 and a drain valve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com