Method for preparing TiO2 (titanium dioxide) nano-pillar array on surface of LED (light-emitting diode) epitaxial wafer

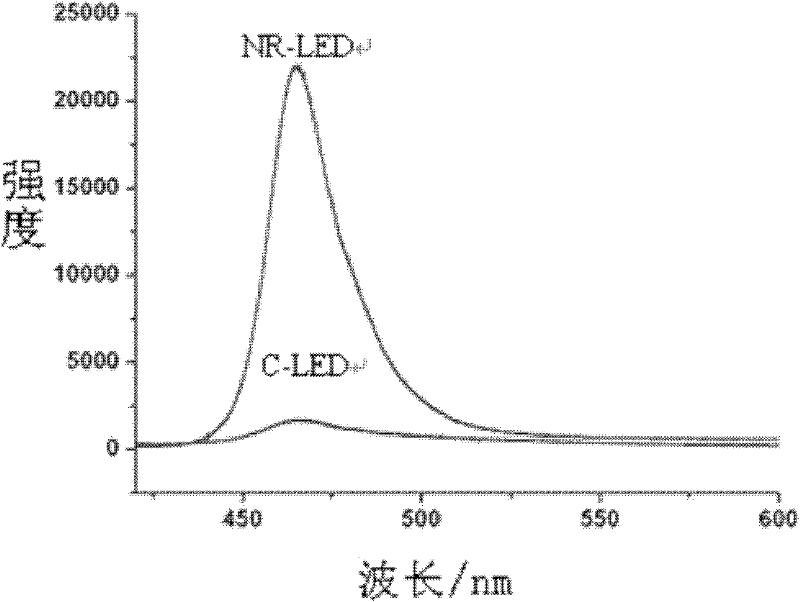

A technology of LED epitaxial wafers and nano-column arrays, which is applied in the field of optoelectronics to achieve the effects of good uniformity, easy periodic arrays, and high controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

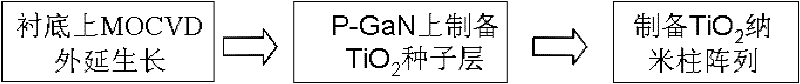

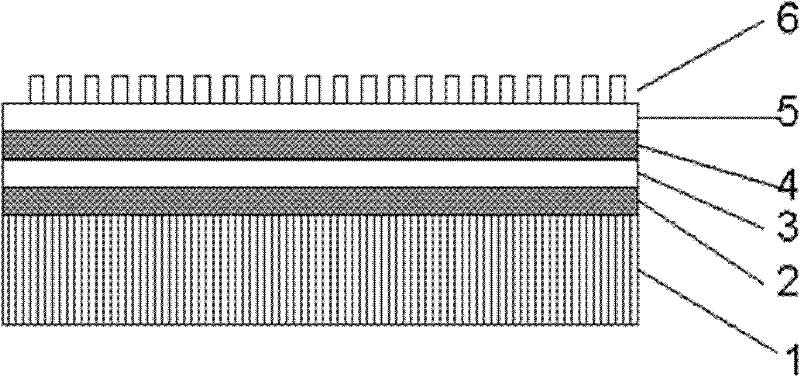

[0020] Such as figure 1 As shown, the present invention uses TiO 2 Nano-pillar arrays improve the photoluminescence efficiency of LED epitaxial wafers. The TiO 2 The preparation method of nanopillar array, because GaN has a hexagonal structure, TiO 2 It is a tetragonal structure, so first grow TiO on GaN 2 When arraying, you need to grow a seed layer. It includes the following steps:

[0021] (1) Using metal organic chemical vapor deposition (MOCVD) method to epitaxially grow N-type GaN layer 2, multiple quantum well active region 3 and P-type GaN layer 4 on sapphire substrate 1 to form epitaxial wafers;

[0022] (2) A layer of 50nm thick titanium is deposited on the surface of P-type GaN and calcined at 500℃ for 3 hours to transform the titanium into TiO 2 , Become TiO 2 As seed layer 5;

[0023] (3) Preparation of TiO by hydrothermal method 2 Nanopillar array 6, put 20mL of 4M HCl solution into the autoclave, stir for 5min at room temperature, add 1mL of tetrabutyl titanate, stir ...

Embodiment 2

[0027] The difference between this embodiment and embodiment 1 is:

[0028] In step (2), a layer of 1nm thick titanium is deposited on the surface of the P-type GaN layer and calcined at 400°C for 1 hour to convert the titanium to TiO 2 ;

[0029] In step (3), put 20 mL of 3M HCl solution into the autoclave, stir at room temperature for 1 min, add 1 mL of tetrabutyl titanate, and stir for 5 min to make a mixed solution; 2 The GaN substrate of the seed layer 5 was put into the mixed solution and leaned against the inner lining wall in a state inclined at 5 degrees to the horizontal plane, reacted at 120° C. for 24 hours, and cooled to room temperature.

Embodiment 3

[0031] The difference between this embodiment and embodiment 1 is:

[0032] In step (2), a layer of 200nm thick titanium is deposited on the surface of P-type GaN, and it is calcined at 600°C for 2 hours to convert the titanium to TiO 2 ;

[0033] In step (3), put 20 mL of 8M HCl solution in the autoclave, stir at room temperature for 10 minutes, add 5 mL of tetrabutyl titanate, and stir for 5 minutes to make a mixed solution; 2 The GaN substrate of the seed layer 5 is put into the mixed solution and leaned against the inner lining wall in an inclined state of 80 degrees with the horizontal plane, reacted at 150° C. for 1 hour, and cooled to room temperature.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com