Preparation method of carbon-supported Pt-based nanometer catalyst

A nano-catalyst and carbon-supported technology, applied in the direction of catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of tedious time-consuming, difficult to control particle size, easy agglomeration, etc., and achieve low product loss , Improve the catalytic reduction ability, the effect of not easy to reunite

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0015] Specific embodiment one: the preparation method of carbon-supported Pt-based nano-catalyst in the present embodiment is carried out according to the following steps:

[0016] 1. Put 1g of activated carbon into 15mL mixed acid solution. The mixed acid solution is prepared from analytically pure concentrated sulfuric acid and analytically pure concentrated nitric acid in a volume ratio of 3:1, then add 150mL triple distilled water, stir at room temperature for 30min, and then cool to room temperature , suction filtered until the filtrate is neutral, and vacuum-dried at 80°C for 10 hours;

[0017] 2. Add 0.1g of activated carbon treated in step 1 into 10mL of ethylene glycol, then ultrasonically oscillate for 2 hours under the condition of ultrasonic frequency of 40kHz and ultrasonic power of 80W, and then add 5.03mL of chloroplatinic acid and chloride Cobalt mixed solution, the molar ratio of Pt element and Co element in the mixed solution of chloroplatinic acid and cobal...

specific Embodiment approach 2

[0018] Embodiment 2: This embodiment is different from Embodiment 1 in that the molar ratio of Pt element to Co element is 3:1. (Obtaining the nanometer Pt-Co / C catalyst means that the mass fraction of Pt in the product is 20%) Other steps and parameters are the same as those in Embodiment 1.

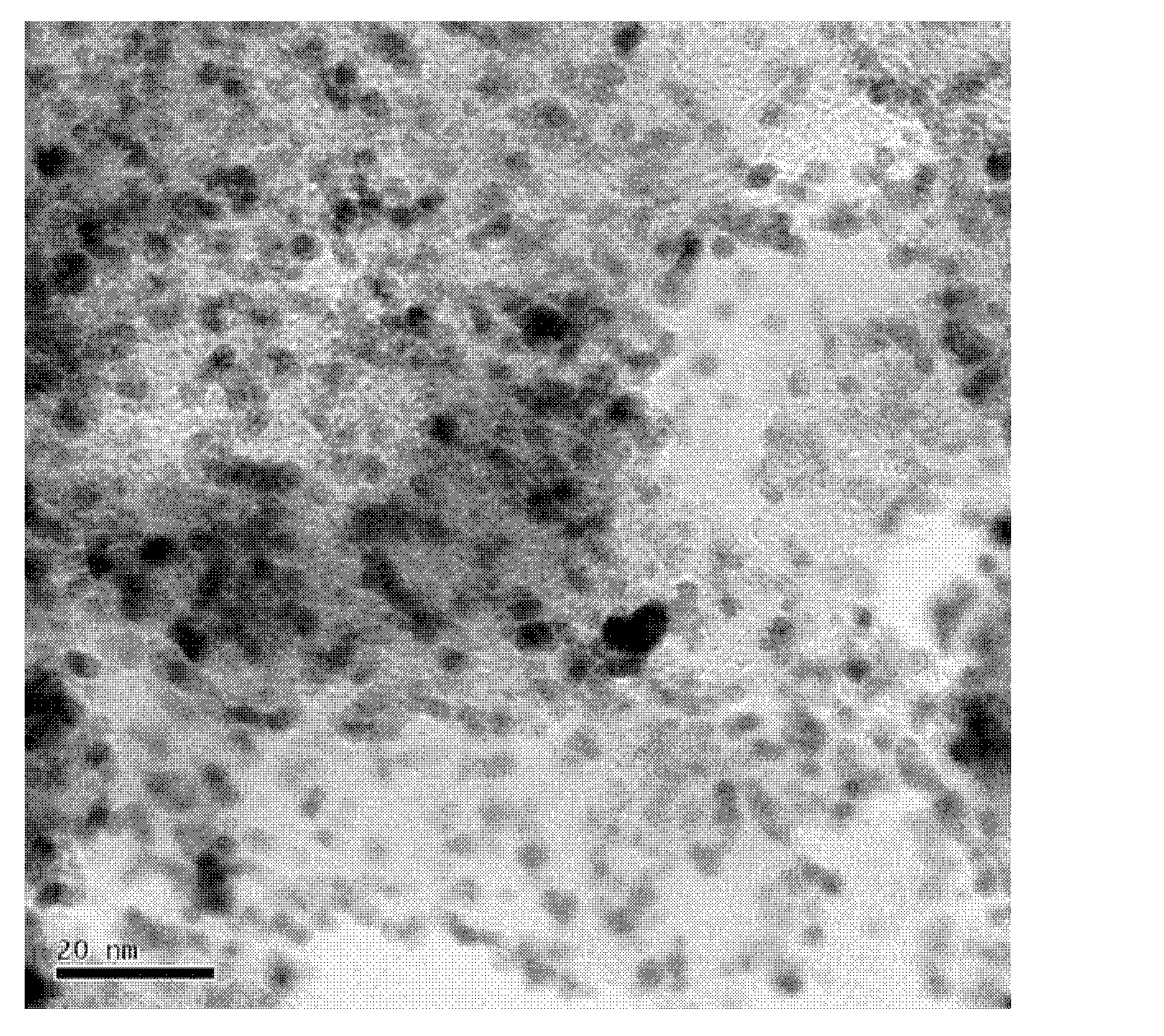

[0019] figure 1 Shown is the TEM photo of the Pt-Co / C catalyst prepared by this method. It can be clearly seen from the photo that the particle size of the catalyst is very uniform, the average particle size is about 3nm, and the particle distribution is uniform.

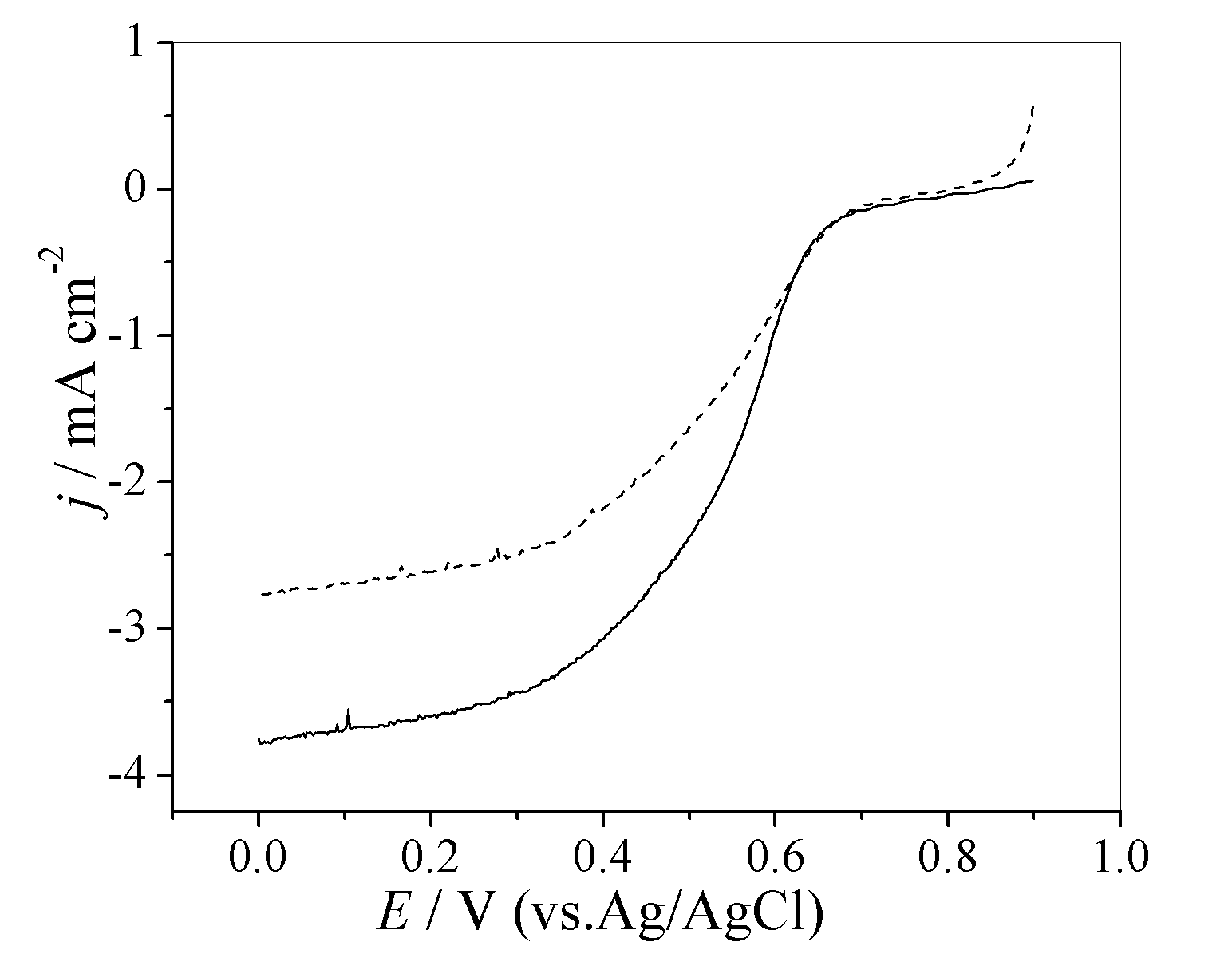

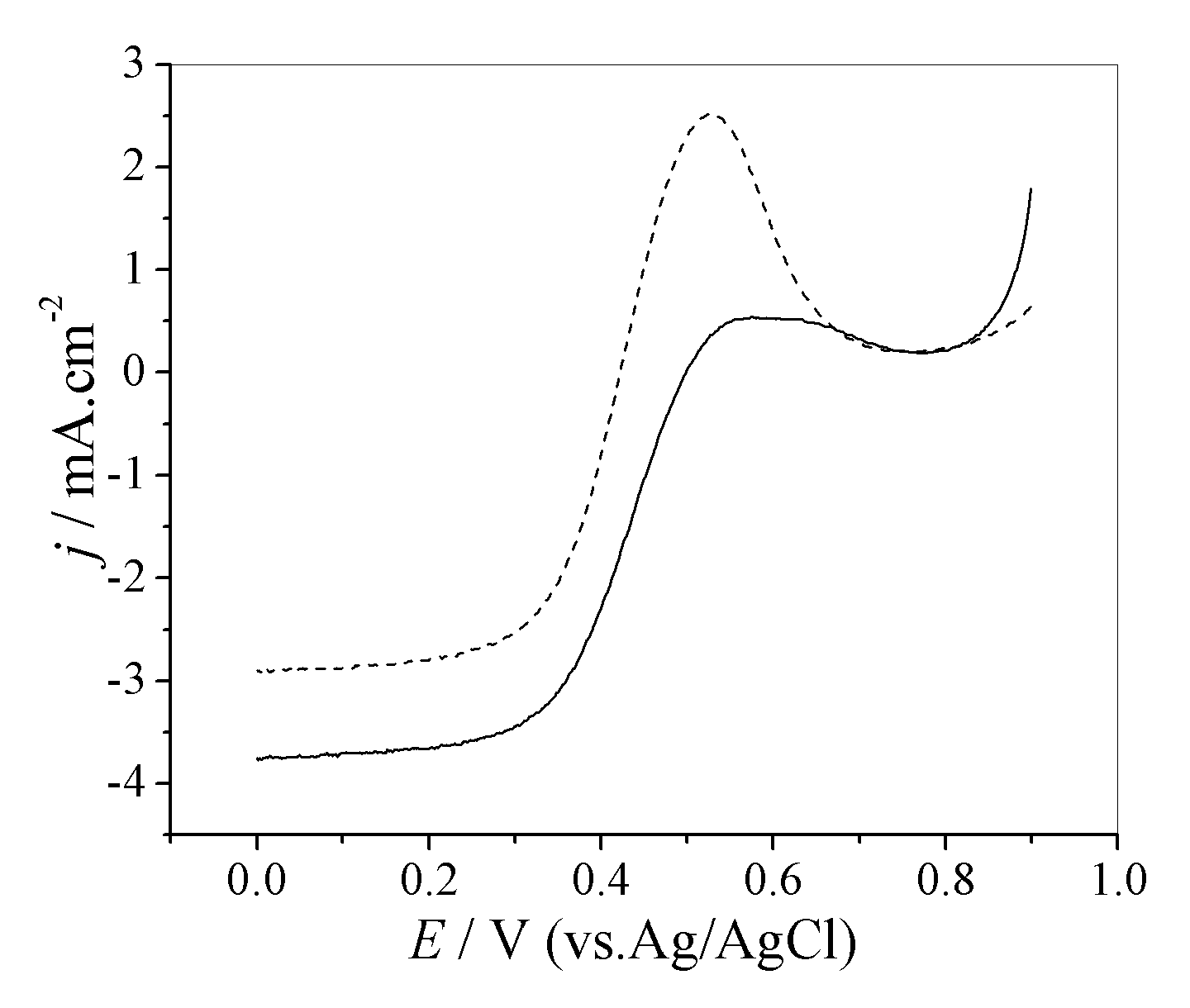

[0020] exist figure 2 Shown embodiment is, the prepared Pt-Co / C of this method (catalyst electrode O 2 Linear scan curve at saturation, 25°C, 0.5mol L -1 h 2 SO 4 solution, 1000 rpm. Experiment specific conditions and steps are as follows: 1, the preparation of working electrode: get the catalyst 5.0mg that makes and 0.2mL water, 0.25mL percentage by weight is 5wt.% Nafion (the solution of the DoPond company that buys...

specific Embodiment approach 3

[0022] Specific embodiment three: the preparation method of carbon-supported Pt-based nano-catalyst in the present embodiment is carried out according to the following steps:

[0023] 1. Put 1g of activated carbon into 15mL mixed acid solution. The mixed acid solution is prepared from analytically pure concentrated sulfuric acid and analytically pure concentrated nitric acid in a volume ratio of 3:1, then add 150mL triple distilled water, stir at room temperature for 30min, and then cool to room temperature , suction filtered until the filtrate is neutral, and vacuum-dried at 80°C for 10 hours;

[0024] 2. Add 0.1g of activated carbon treated in step 1 into 10mL of ethylene glycol, then ultrasonically oscillate for 2 hours under the condition of ultrasonic frequency of 40kHz and ultrasonic power of 80W, and then add 5.03mL of chloroplatinic acid and chloride Cobalt mixed solution, the molar ratio of Pt element and Co element in the mixed solution of chloroplatinic acid and cob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com