Laser cutting machine tool for quartz crystal

A technology of laser cutting and processing machine tools, applied in laser welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of time-consuming and labor-intensive, difficult to meet processing requirements, low processing efficiency, etc., to achieve a good overall feeling, simple and elegant appearance , the effect of high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

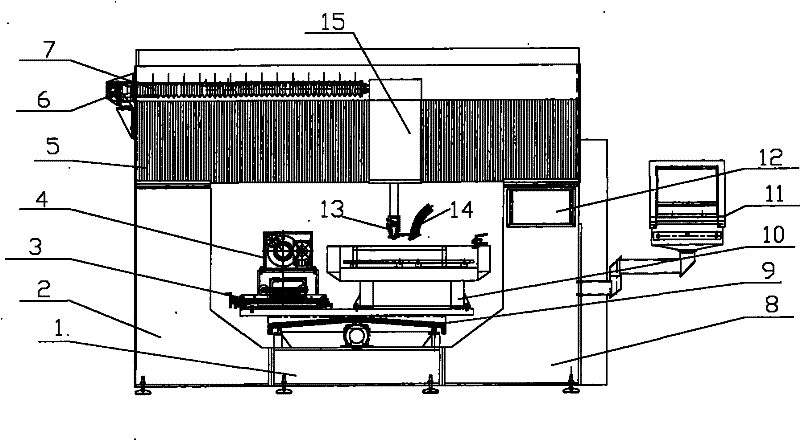

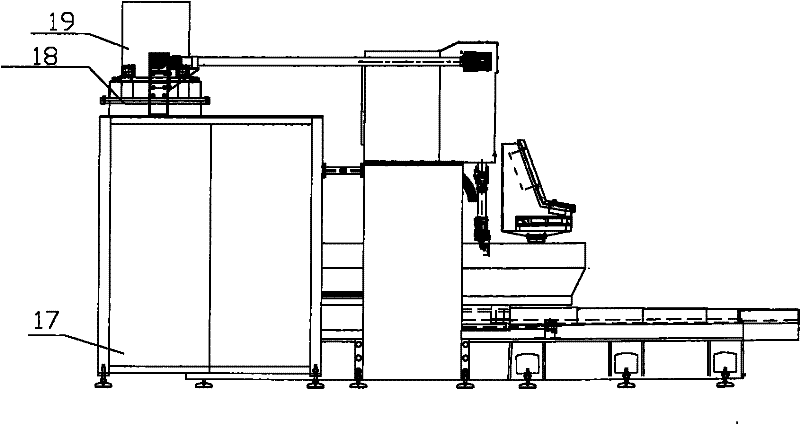

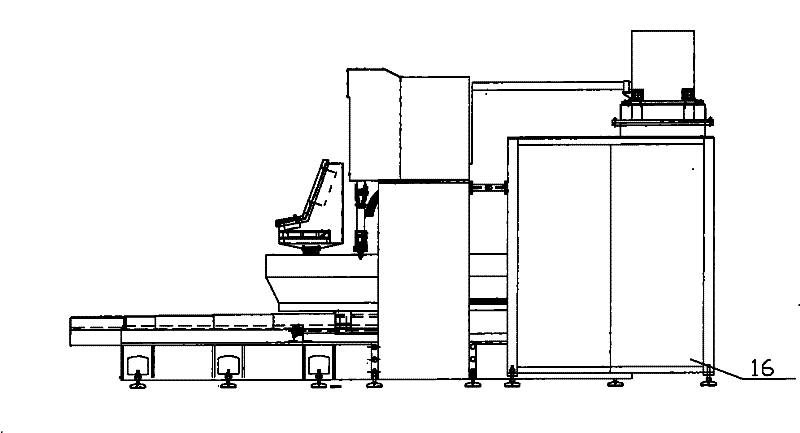

[0021] Laser cutting uses a focused high-power-density laser beam to irradiate the workpiece. Under the premise of exceeding the threshold power density, heat energy is absorbed by the material, which causes the temperature of the material at the irradiation point to rise sharply. After reaching the boiling point, the material begins to vaporize and pores form. As the beam moves relative to the workpiece, a kerf is formed in the material. The slag at the kerf is blown off by auxiliary gas at a certain pressure. The laser cutting method of quartz crystal plate and tube is obviously superior to the traditional processing method. The mechanism of cutting quartz crystal with laser is laser beam sublimation cutting. The task of air flow during sublimation cutting is to blow the vaporized substance away from the kerf before the surface lay...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com