Silver doped titanium dioxide thin film and preparation method thereof

A titanium dioxide, silver doping technology, applied in the direction of nanostructure manufacturing, manipulating single atoms, nanotechnology, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] 1) Preparation of TiO 2 sol, the TiO 2 The sol is composed of tetrabutyl titanate with a mass fraction of 20.00%, hydrochloric acid with a mass fraction of 8.00% and ethanol in the balance;

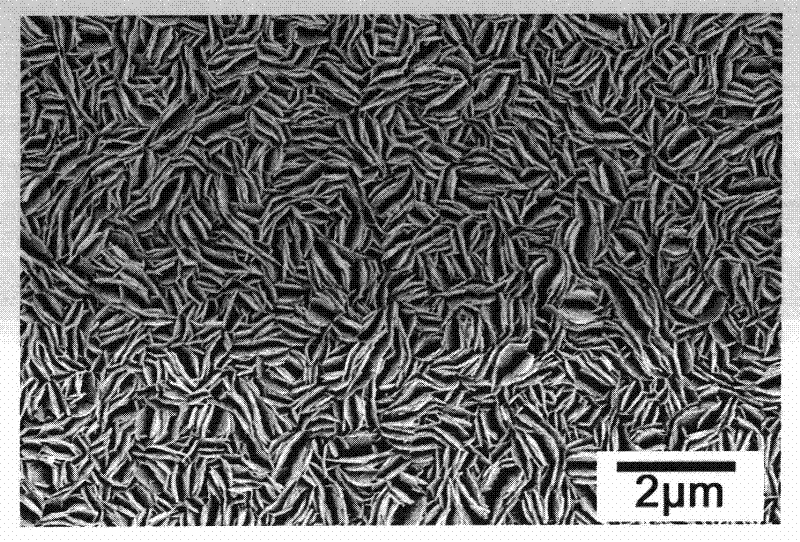

[0027] 2) with the TiO obtained in step 1) 2 The sol is coated on the surface of a clean glass substrate, and the coating amount is 12mL / m 2 , and then the coated TiO 2 The glass substrate of the sol is calcined at 500°C for 2 hours in a muffle furnace; TiO with a diameter of 20-50nm is obtained on the surface of the glass substrate 2 nanoparticles;

[0028] 3) Preparation of Ag / TiO for solvothermal synthesis 2 Precursor sol, the Ag / TiO 2 The precursor sol is composed of tetrabutyl titanate with a mass fraction of 2.00%, silver nitrate with a mass fraction of 1.00%, and the balance of glacial acetic acid;

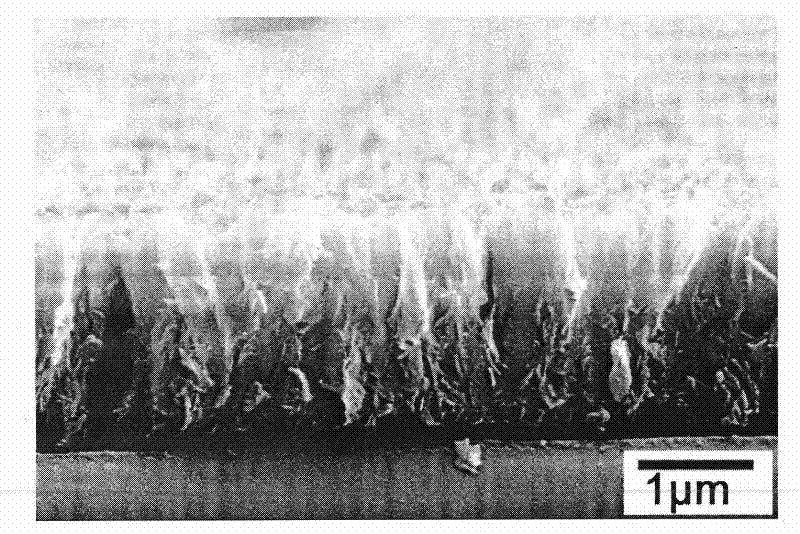

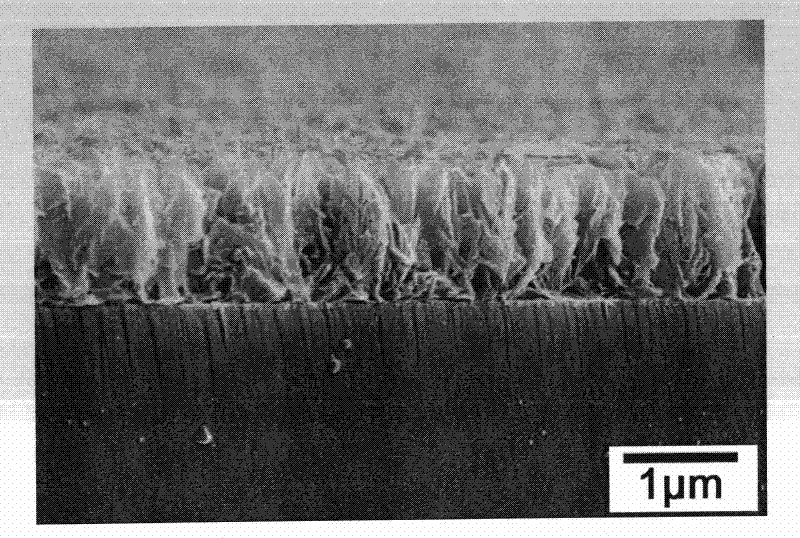

[0029] 4) covered with TiO obtained in step 2) 2The Ag / TiO 2 In the precursor sol, seal the container and put it in an oven, heat it at 150°C for 48 hours, take out the...

Embodiment 2

[0031] 1) Preparation of TiO 2 sol, the TiO 2 The sol is composed of tetraethyl titanate with a mass fraction of 12.50%, hydrochloric acid with a mass fraction of 6.00% and ethanol in the balance;

[0032] 2) with the TiO obtained in step 1) 2 The sol is coated on the surface of a clean silicon wafer substrate, and the coating amount is 20mL / m 2 , and then the coated TiO 2 The silicon substrate of the sol was calcined at 550°C for 3 hours in a muffle furnace; TiO with a diameter of 10-50nm was obtained on the surface of the silicon substrate. 2 nanoparticles;

[0033] 3) Preparation of Ag / TiO for solvothermal synthesis 2 Precursor sol, the Ag / TiO 2 The precursor sol is composed of tetrapropyl titanate with a mass fraction of 1.50%, silver fluoride with a mass fraction of 0.50%, and the balance of glacial acetic acid;

[0034] 4) covered with TiO obtained in step 2) 2 Step 3) Ag / TiO obtained by immersing the nanoparticle silicon wafer substrate into the container 2 In ...

Embodiment 3

[0036] 1) Preparation of TiO 2 sol, the TiO 2 The sol is composed of tetrapropyl titanate with a mass fraction of 8.60%, hydrochloric acid with a mass fraction of 2.00% and the rest of ethanol;

[0037] 2) with the TiO obtained in step 1) 2 The sol is coated on the surface of a clean silicon wafer substrate, and the coating amount is 2mL / m 2 , and then the coated TiO 2 The silicon substrate of the sol is calcined in a muffle furnace at 450°C for 1 hour; TiO with a diameter of 10-20nm is obtained on the surface of the silicon substrate. 2 nanoparticles;

[0038] 3) Preparation of Ag / TiO for solvothermal synthesis 2 Precursor sol, the Ag / TiO 2 The precursor sol is composed of tetraethyl titanate with a mass fraction of 0.25%, silver acetate with a mass fraction of 0.05% and the balance of glacial acetic acid;

[0039] 4) covered with TiO obtained in step 2) 2 Step 3) Ag / TiO obtained by immersing the nanoparticle silicon wafer substrate into the container 2 In the precur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com