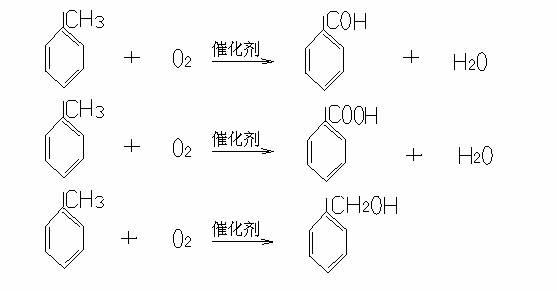

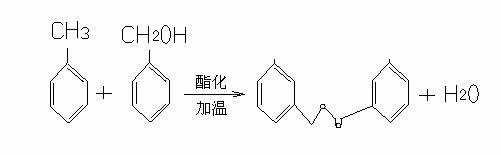

Method for preparing benzaldehyde, benzyl alcohol and benzyl benzoate through air catalytic oxidation of methylbenzene

A technology of benzyl benzoate and catalytic oxidation, which is applied in the field of preparation of benzaldehyde, benzyl alcohol, and benzyl benzoate, can solve problems such as corrosion and hidden dangers of production safety, and achieve low production costs, easy regeneration, and considerable economic benefits Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Add 500 grams of toluene to a 1000 ml pressure reactor, and at the same time add 6 grams of manganese sulfate, 2 grams of manganese acetate, and 1 gram of cerium sulfate to the reactor, close the mouth of the kettle, and when the temperature of the oil bath reaches 180 ° C, gradually introduce compressed air. The molar ratio of the amount of air added to toluene is 8:1, the temperature of the reactor is controlled at about 180°C, the pressure is 1.0 Mpa, and the gas supply is 1000ml / min. After 2 hours of reaction, stop the reaction and cool down to room temperature. The mixture was tested by internal standard method of Wenling 9700 gas chromatography, and the conversion rate of toluene was 11%, benzoic acid was 2%, benzaldehyde was 3.1%, and benzyl alcohol was 5.8%. The oxidizing solution mixture is first separated from toluene at normal pressure, and then reused in the oxidation tower for repeated reactions. The remaining high boilers are fractionated under reduced pres...

Embodiment 2

[0022] Add 500 grams of toluene to a 1000ml pressure reactor, add 5 grams of manganese sulfate and 2 grams of sodium acetate, close the mouth of the kettle, and when the oil bath is heated to 200 degrees, gradually introduce compressed air, and the molar ratio of the amount of air added to toluene is 6: 1. Control the reaction temperature to about 160 degrees, the air flow rate to 800 ml / min, the pressure to 0.6 Mpa, and the oxidation time to 1 hour, stop the reaction, and cool down to room temperature. The mixture was tested by internal standard method of Wenling 9700 gas chromatography, and the conversion rate of toluene was 10.2%, benzoic acid was 1.97%, benzaldehyde was 3.1%, benzyl alcohol was 4.9%. The oxidizing solution mixture is separated from the toluene at normal pressure, and then returned to the oxidation tower for repeated reactions. The remaining high boilers are fractionated under reduced pressure to obtain benzaldehyde, benzyl alcohol, and benzyl benzoate. Pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com