Preparation method and application of bitter gourd dietary fiber

A technology of dietary fiber and bitter gourd, which is applied in the field of preparation of bitter gourd dietary fiber, to achieve the effect of obvious regulation of blood sugar, wide source and obvious effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

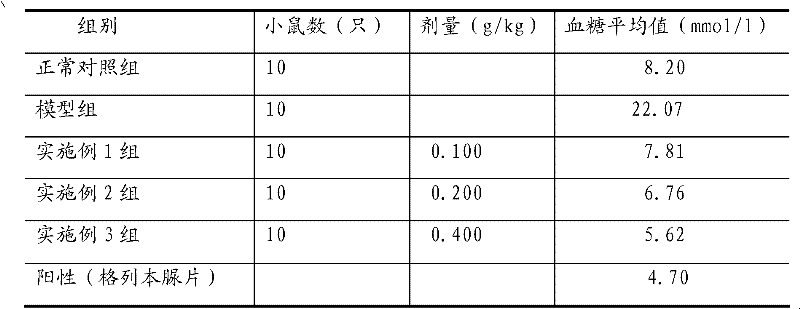

Examples

Embodiment 1

[0027] Take 1000.0g of bitter gourd, wash it dry, cut into sections, add 10L of water to make a slurry, pass the slurry through a colloid mill for 3 times, and pass through a high-pressure homogenization for 3 times. Heat to 100°C for 180 min, then cool down to room temperature. Ultrasonic treatment, the treatment conditions are 5000W, 90min. Adjust the pH value to 7.5 with 10 mol / L NaOH solution, and add 20,000 international units (specific activity) of neutral protease for enzymolysis at 50°C for 500 minutes. After protease hydrolysis, adjust the pH value to 7.5 with 10mol / L NaOH solution, heat up to 100°C, and add 20,000 international units (specific activity) of amylase for enzymolysis for 180 minutes. After enzymatic hydrolysis, heat to 95°C for 10 minutes, then cool down to room temperature. Centrifuge and filter to obtain 4.8L of filtrate and filter residue. Take 4.8L of the filtrate and add 95% ethanol to a final concentration of 85%, let stand overnight, centrifuge...

Embodiment 2

[0033] Take 1000.0g of bitter gourd, wash it dry, cut into sections, add 4L of water to make a slurry, pass the slurry once through a colloid mill, and once through a high-pressure homogenization. Heat to 80°C for 30 minutes, then cool down to room temperature. Ultrasonic treatment, the treatment conditions are 500W, 20min. Adjust the pH value to 6.5 with 10 mol / L NaOH solution, and add 1,000 international units (specific activity) of protease for enzymolysis at 40°C for 180 minutes. After the enzymatic hydrolysis with neutral protease, adjust the pH value to 6.5 with 10 mol / L NaOH solution, heat to 50°C, and add 0.1 thousand international units (specific activity) of amylase for enzymatic hydrolysis for 30 minutes. After enzymatic hydrolysis, heat to 95°C for 10 minutes, then cool down to room temperature. Centrifuge and filter to obtain 2.2L of filtrate and filter residue. Take 2.2L of the filtrate and add 95% ethanol to a final concentration of 60%, let it stand overnigh...

Embodiment 3

[0039] Take 1000.0g of bitter gourd, wash it dry, cut into sections, add 7L of water to make a slurry, pass the slurry once through a colloid mill, and once through a high-pressure homogenization. Heat to 90°C for 120min, then cool down to room temperature. Ultrasonic treatment, the treatment conditions are 3000W, 60min. Adjust the pH value to 7.0 with 10 mol / L KOH solution, and add 10,000 international units (specific activity) of protease for enzymolysis at 45°C for 240 minutes. After the enzymatic hydrolysis with neutral protease, adjust the pH value to 7.0 with 10 mol / L KOH solution, heat up to 80°C, and add 10,000 international units (specific activity) of amylase for enzymatic hydrolysis for 120 minutes. After enzymatic hydrolysis, heat to 95°C for 10 minutes, then cool down to room temperature. Centrifuge and filter to obtain 3.6L of filtrate and filter residue. Take 3.6L of the filtrate and add 95% ethanol to a final concentration of 75%, let stand overnight, centri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com