Manufacture method for cutting liquid crystal display panel

A technology for liquid crystal display panels and manufacturing methods, which is applied in the direction of manufacturing tools, glass manufacturing equipment, glass cutting devices, etc., which can solve the problems of increased seam width of cutting screens, rough edges of liquid crystal panels, and only straight lines, etc., to achieve low cutting The effect of process cost, cutting cost reduction and yield improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] The invention discloses a method for cutting and manufacturing a liquid crystal display panel, comprising:

[0044] a. Disassemble and separate the LCD panel:

[0045] Disassemble the LCD screen panel from the LCD display;

[0046] b. Paste protective film: Paste a layer of plastic protective film on the polarizers on both sides of the LCD panel;

[0047] c. Positioning: According to the requirements of the cut size, plan the edge position of the LCD panel along the cutting direction, and remove the polarizer with the protective film to be cut off, and obtain the required chemical thinning on both sides of the LCD panel Protected and non-protected areas;

[0048] d. Thinning: Put the non-protected area of the LCD panel obtained in step c into the chemical thinning solution, adjust the degree of thinning by controlling the length of time, and obtain a cut area with a thickness of 0.1-0.2mm, take out the LCD panel and rinse ,drying;

[0049] e. Fragmentation: Use a ...

Embodiment 2

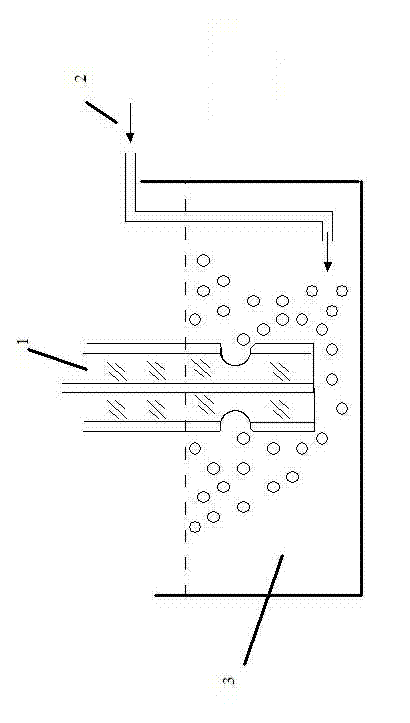

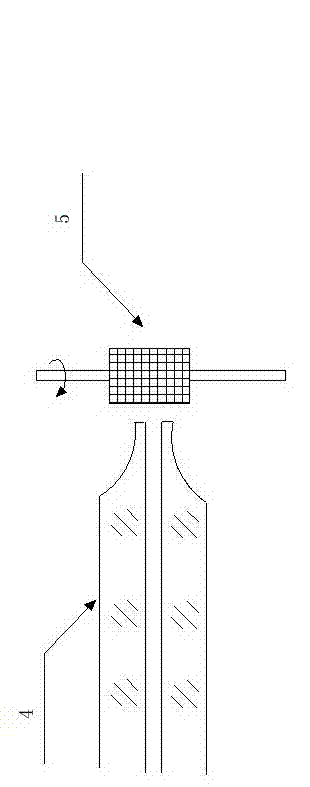

[0052] As a preferred embodiment of the present invention, on the basis of Example 1, refer to the description attached figure 2 , after step e, there are: f, edging: place the LCD panel on the glass edging machine for positioning, determine the diamond grinding tool's walking route; use the diamond grinding wheel to grind the broken section, and the diamond grinding tool will start from the cutting edge Grinding the thickness area of 0.1-0.2mm after the LCD panel is thinned in the longitudinal direction. In the d step, refer to the attached figure 1 , the temperature of the chemical thinning liquid is maintained at 50 degrees Celsius, and the chemical thinning liquid is stirred by bubbling.

Embodiment 3

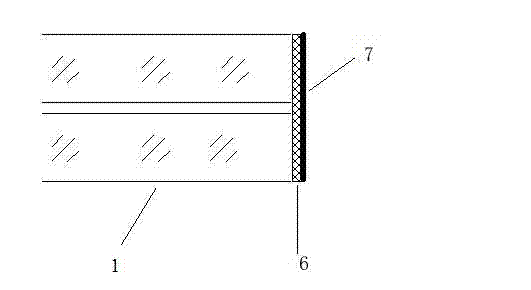

[0054] As the best implementation mode of the present invention, on the basis of embodiment 2, refer to the attached description image 3 , after the f step there is:

[0055] g. Film edge sealing: Use epoxy resin to seal the edge-grinding section of the fractured part of the LCD panel, and seal the edge with a metal film.

[0056] h. Connecting and forming, putting the edge-sealing LCD panel into a matching module to obtain an active matrix liquid crystal display with a special aspect ratio.

[0057] One side or two adjacent sides of the display are cutting edges, and sealing glue is encapsulated on the cutting edges. The sealing glue is in contact with the upper polarizer, the upper glass substrate, the liquid crystal material, the lower glass substrate and the lower polarizer of the display respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com