Fluorescent polynaphthalene as well as preparation method and application thereof

A fluorescent and polynaphthalene technology, applied in the field of analytical chemistry, can solve the problems of low molecular weight of polynaphthalene, and achieve the effects of low preparation cost, wide application prospects, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~9

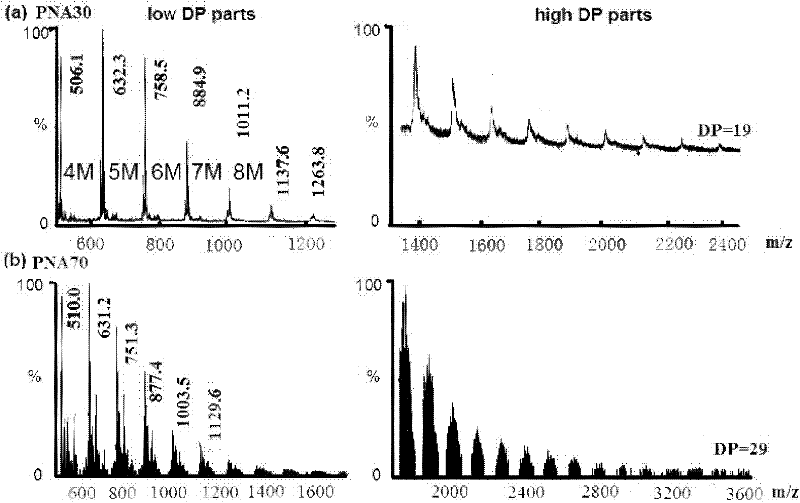

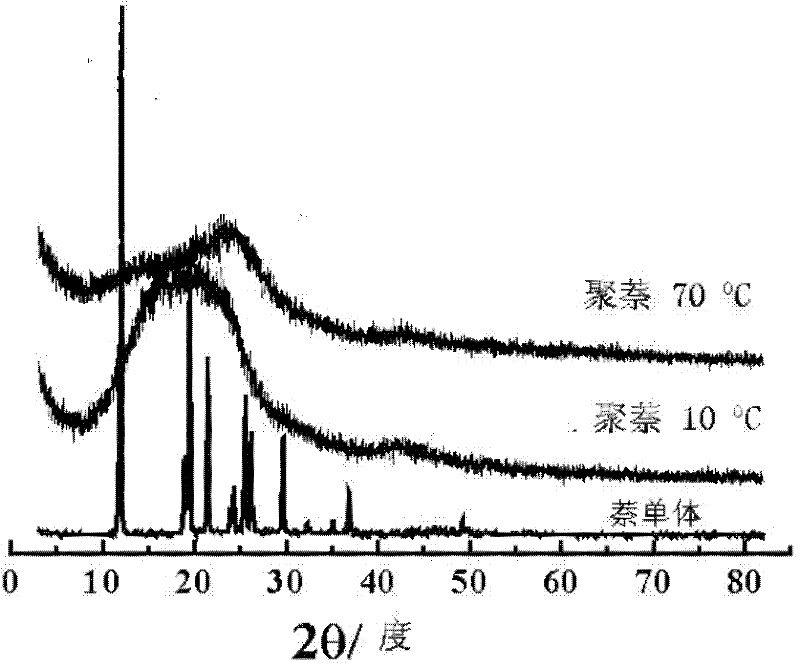

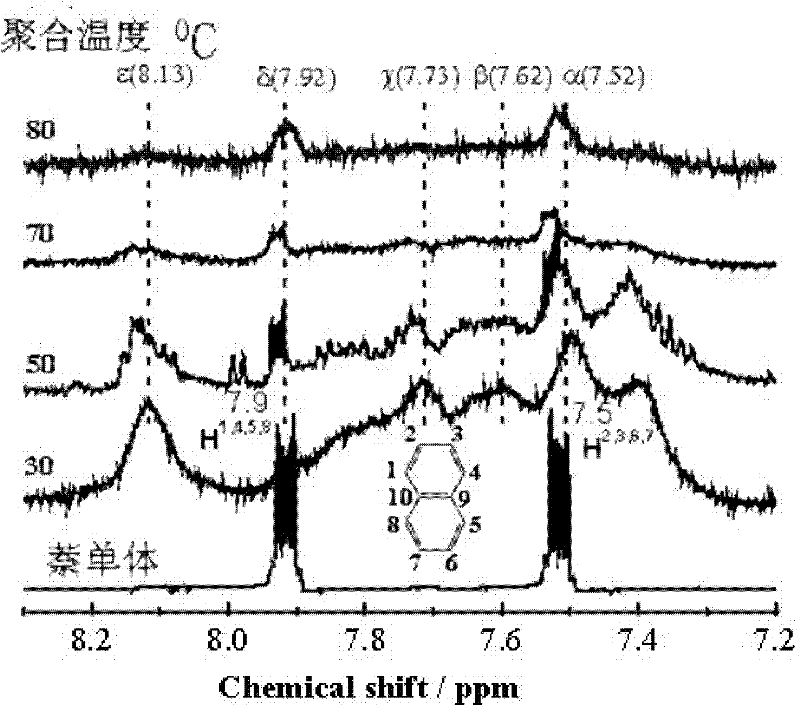

[0038] Embodiment 1~9: the synthesis of polynaphthalene

Embodiment 1

[0039] Embodiment 1: the iron trichloride of 1622.0mg (10.00mmol) is dissolved in 20mL nitromethane, ultrasonic 10 minutes promotes its dissolution, adopts single-layer filter paper to filter then, removes impurity, obtains the nitromethane of ferric chloride solution, and use precision pH test paper to measure the pH value of the ferric chloride solution; dissolve 2564 mg (2.00 mmol) of naphthalene monomer in 5 mL of nitromethane, and ultrasonically promote its dissolution for 5 minutes. The nitromethane solution of ferric chloride and the nitromethane solution of naphthalene were respectively placed in a constant temperature water bath with a temperature of 50° C. for 30 minutes. Then add the nitromethane solution of ferric chloride into the nitromethane solution of naphthalene monomer at one time, turn on the stirring device, and closely observe the reaction phenomenon. Dip the mixed solution with a glass rod to measure its pH value, and put a wet precision pH test paper on...

Embodiment 2

[0040] Embodiment 2: repeat embodiment 1, but change oxidizing agent and monomer molar ratio and be 3 / 1, promptly take by weighing ferric chloride 984.42mg (6.00mmol), all the other operations are the same as embodiment 1, obtain polynaphthalene productive rate and be 50.1% .

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com