Tripentaerythritol-based polypropylene halogen-free flame retardant and preparation method thereof

A technology of tripentaerythritol and polypropylene, which is applied in the field of flame retardant, can solve the problems of few in-depth research on carbon sources, high hydrophilicity, and difficult processing, and achieves environmental adaptability, good flame retardant performance, and long-term stable application performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

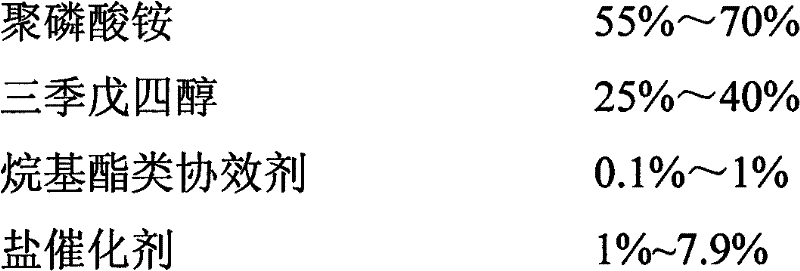

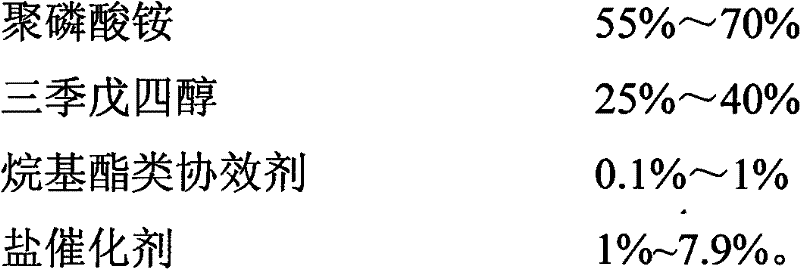

Embodiment 1

[0020] Grind 67g of ammonium polyphosphate (polymerization degree > 1000, water solubility of 0.5g / 100mL water), 30g of tripentaerythritol, 1g of trialkyl phosphate and 2g of nickel borate respectively, dry and mix, and stir evenly Finally, the polypropylene halogen-free flame retardant based on tripentaerythritol is obtained, which is in the form of white powder, and is stored in bags with heat and moisture insulation.

[0021] 30.5 g of the obtained tripentaerythritol-based polypropylene halogen-free flame retardant was dried at 60° C. for 4 h and mixed evenly with 69.3 g of polypropylene, 0.1 g of antioxidant 1010 and 0.1 g of antioxidant 168 to obtain A mixture, the obtained mixture is melted, kneaded, extruded, cooled, pelletized and dried on a twin-screw extruder with a diameter of 20 mm to obtain a halogen-free flame-retardant polypropylene composition pellet; the obtained halogen-free flame-retardant polypropylene composition pellet; After drying the pellets of the fla...

Embodiment 2

[0024] The ammonium polyphosphate of 62g (polymerization degree > 1000, water solubility is 0.5g / 100mL water), the dipentaerythritol of 33g, the dialkyl ester of the aromatic tetracarboxylic acid of 0.4g and the magnesium sulfate of 4.6g are ground respectively, Mix after drying, and stir evenly to obtain a tripentaerythritol-based polypropylene halogen-free flame retardant, which is in the form of white powder, and is stored in a heat-insulated and moisture-proof bag.

[0025] After drying 30.5 g of the obtained tripentaerythritol-based polypropylene halogen-free flame retardant at 60° C. for 4 h, mix it uniformly with 69.2 g of polypropylene, 0.1 g of antioxidant 1010 and 0.2 g of antioxidant 168 to obtain a Mixture, the obtained mixture is melted, kneaded, extruded, cooled, pelletized and dried on a twin-screw extruder with a diameter of 20 mm to obtain a halogen-free flame-retardant polypropylene composition pellet; the obtained halogen-free flame-retardant After the polyp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

| Thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com