Method for improving desulfurization and denitrification efficiencies of flue gas in biomembrane packing tower by using artificial compound functional bacteria simultaneously

A denitrification efficiency and biofilm technology, which is applied in the field of biological industrial waste gas purification, can solve the problems of the adverse effects of desulfurization and denitrification, the weak ability of the micro-ecosystem to resist the impact of changes in external conditions, etc. Ecosystem optimization, functional microbial population structure, and the effect of improving the micro-ecosystem and increasing the type and quantity of bacteria

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3

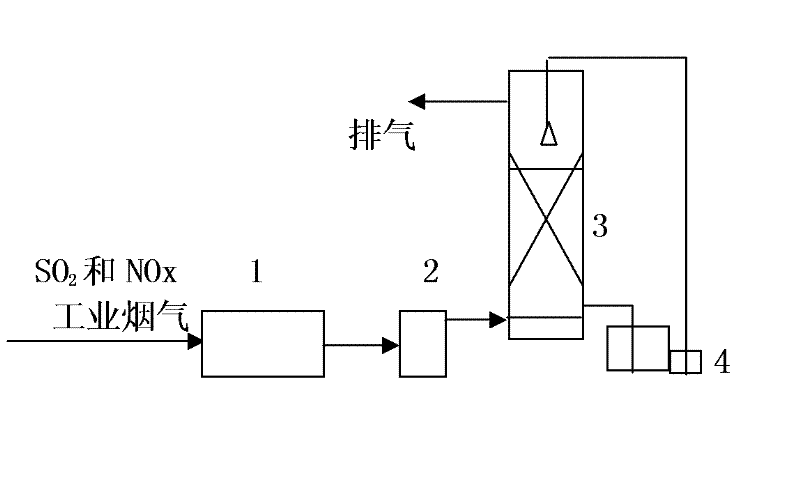

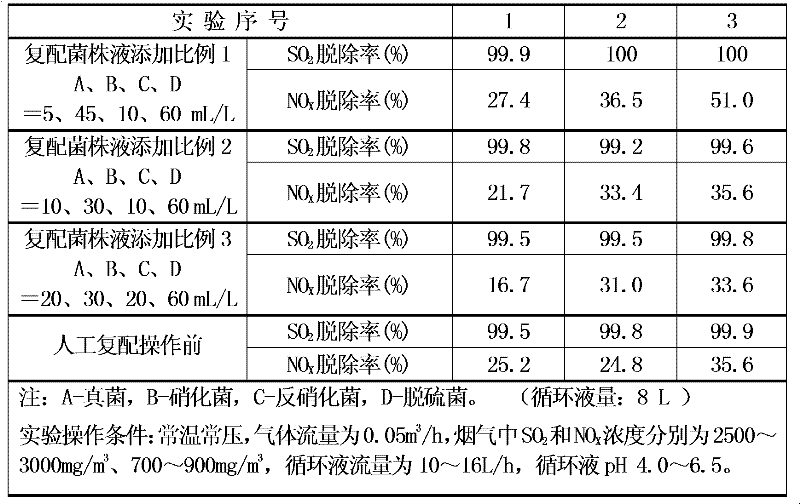

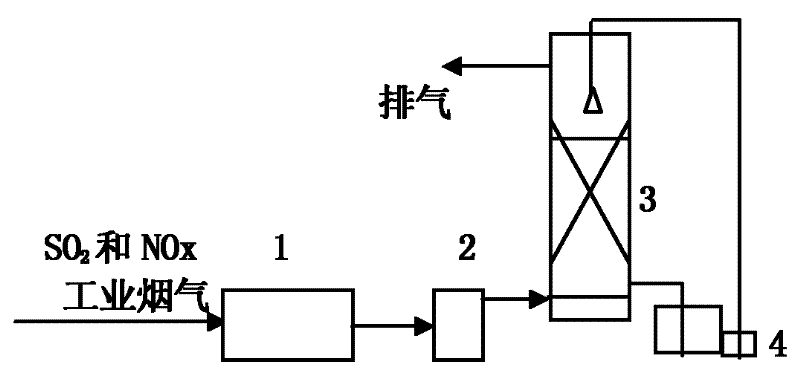

[0025] Simultaneous removal of SO in flue gas by artificially compounding functional bacteria on a biofilm packed tower system for waste gas purification 2 and NOx treatment experiments. The biofilm packed tower system consists of a pre-processor, an induced draft fan, a biofilm packed tower, a circulating liquid storage tank and a circulating pump. figure 1 shown. The biofilm packed tower is a small glass biofilm packed tower with a tower diameter of 55mm. The packed tower is filled with spherical ceramsite with a diameter of 15-25mm, and the packing volume is 1.19L. The experimental operations were carried out under normal temperature and pressure conditions, and the gas flow rate was 0.05m. 3 / h, SO in flue gas 2 and NO x The concentration is 2500~3000mg / m 3 , 700~900mg / m 3 , the circulating fluid flow is 10~16L / h, and the circulating fluid pH is 4.0~6.5. Use 10% NaHCO when the pH of the circulating fluid decreases 3 buffer to adjust. Biofilm packed tower inlet and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com