Enzymolysis method for starchy material and method for preparing citric acid

A starch raw material and amylase technology, which is applied in the directions of microorganism-based methods, biochemical equipment and methods, microorganisms, etc., can solve the problems of low yield of liquefied clear liquid, high viscosity of filter residue, and high consumption of sugar-making grains, so as to reduce the Residual starch content, the effect of reducing grain consumption and cost, and reducing grain consumption for sugar production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

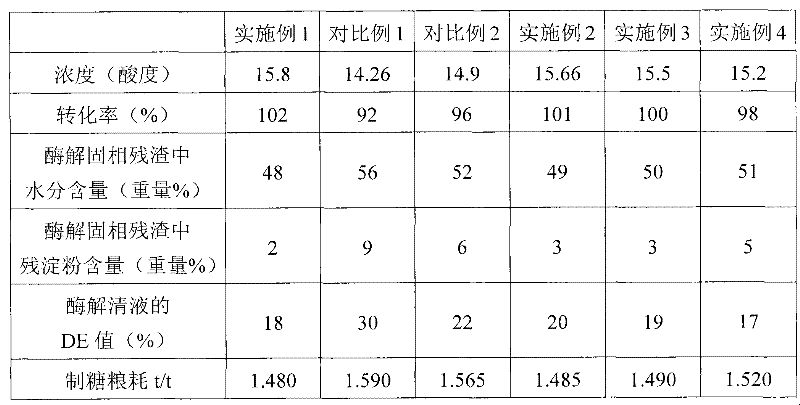

Examples

preparation example Construction

[0031] The present invention also provides a method for preparing citric acid. The method includes inoculating Aspergillus niger into a fermentation broth and fermenting to produce citric acid. The fermentation broth contains an enzymatic hydrolysis product of a starch material, characterized in that the starch The preparation method of the enzymatic hydrolysis product of the raw material is the above-mentioned enzymatic hydrolysis method.

[0032] According to the present invention, the content of each component in the fermentation broth can be changed within a wide range, and preferably, a supplementary nitrogen source can be added to the fermentation broth as needed, and the content of the supplementary nitrogen source can be 0.05-0.2% by weight of the total weight of the fermentation broth. According to the present invention, the type of the supplementary nitrogen source is well known to those skilled in the art. For example, the supplementary nitrogen source may be at least ...

Embodiment 1

[0053] This example is used to illustrate the enzymatic hydrolysis method of corn raw material and the method of preparing citric acid of the present invention.

[0054] (1) Crushing of corn raw materials

[0055] 100 parts by weight of corn (moisture content of 14% by weight) were pulverized to obtain a pulverized product with an average particle diameter of 400 microns, and the pulverized product was mixed with 300 parts by weight of water to obtain a starch slurry.

[0056] (2) Enzymatic hydrolysis

[0057] At 50 ℃, the starch slurry obtained in step (1) (the pH value is adjusted to 6.0) is mixed with 30% by weight of the total weight of the amylase (the total amount of amylase is based on the crushed per gram Based on the dry weight of the product, add 30 enzyme activity units of high-temperature resistant α-amylase) to obtain a mixture, and spray the mixture with steam at 170°C in an ejector (the weight ratio of steam to mixture is 0.05:1) , The contact time is 2 seconds, so tha...

Embodiment 2

[0074] This example is used to illustrate the enzymatic hydrolysis method of corn raw material and the method of preparing citric acid of the present invention.

[0075] (1) Crushing of corn raw materials

[0076] 100 parts by weight of the same corn raw material as in Example 1 was pulverized to obtain a pulverized product with an average particle diameter of 600 microns, and the pulverized product was mixed with 300 parts by weight of water to obtain a starch slurry.

[0077] (2) Enzymatic hydrolysis

[0078] At 60°C, the starch slurry obtained in step (1) (pH adjusted to 7.0) is mixed with 40% by weight of the total weight of amylase enzyme (the total amount of amylase is based on the amount of crushed per gram Based on the dry weight of the product, add 20 enzyme activity units (high temperature resistant α-amylase) to obtain a mixture, and spray the mixture with steam at 160°C in an ejector (the weight ratio of steam to mixture is 0.06:1) , The contact time is 3 seconds, so that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com