Zero point self adjustment and calibration method for catalytic gas sensor

A gas sensor, catalytic technology, applied in the direction of material resistance, which can solve the problems of short calibration period and inability to realize real-time self-calibration zero point.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

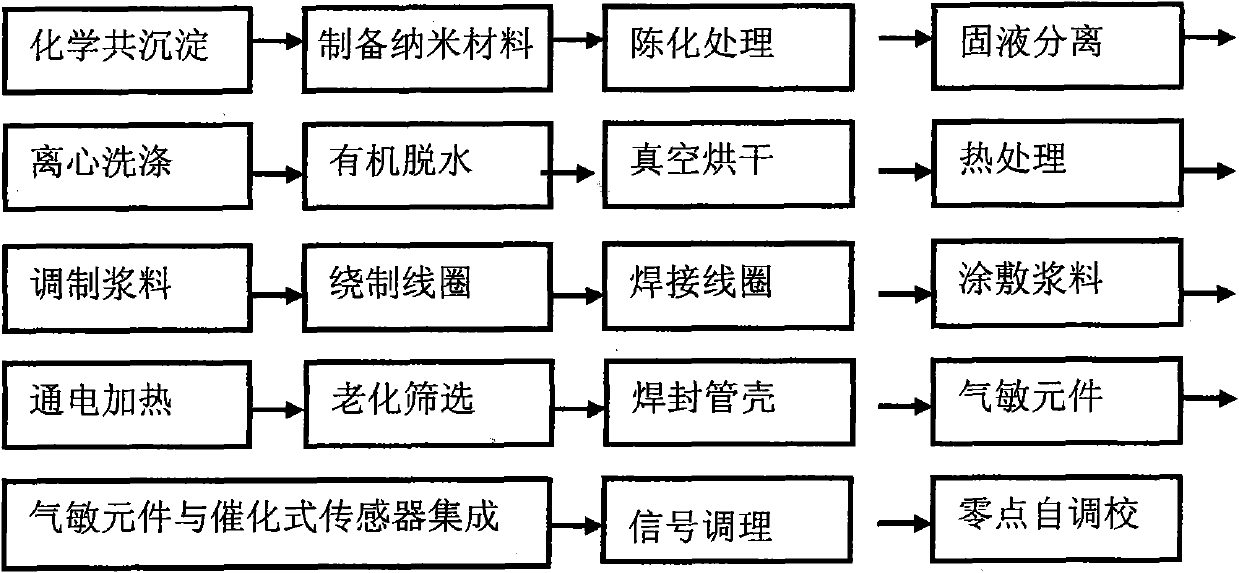

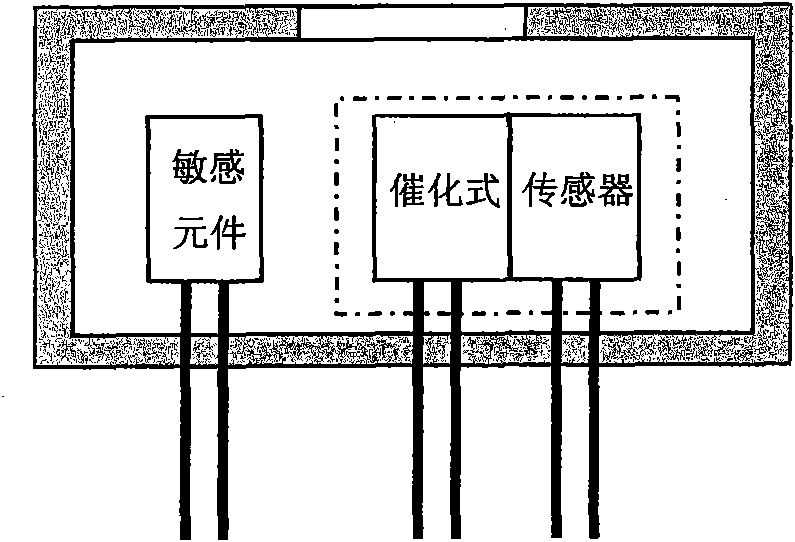

[0023] refer to figure 1 , indicating the process flow chart for the preparation of low-range gas sensor sensors. The process consists of the following process steps: preparation of nanocomposites-aging-solid-liquid separation-washing-dehydration-drying-heat treatment-slurry-coil winding- Welding-coating-heating-tube sealing-integration with catalytic gas sensor-zero point self-adjustment. The manufacturing methods between the various steps can be combined according to specific requirements.

[0024] The specific implementation is as follows:

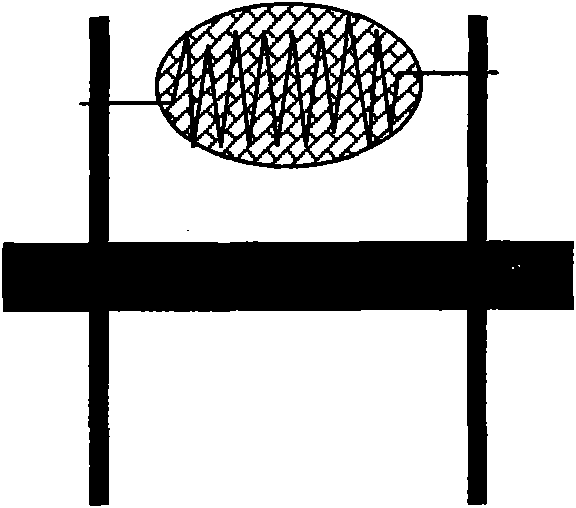

[0025] a. The nano-semiconductor tin dioxide, antimony pentoxide and cerium oxide composite sensitive materials are prepared by chemical co-precipitation method, and the materials are formed after aging, centrifugal solid-liquid separation, deionized washing, organic solvent dehydration, vacuum drying and heat treatment For sensitive materials with lower resistivity, when the sensitive material forms a spherical body with a diameter o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com