Method for separating and recovering sulfur and arsenic from sulfur and arsenic containing materials

A technology for separation and recovery of materials, applied in magnetic separation, solid separation, chemical instruments and methods, etc., can solve problems such as difficult separation of sulfur-containing and arsenic minerals, and achieve good economic benefits, good separation effects, and high resource utilization. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

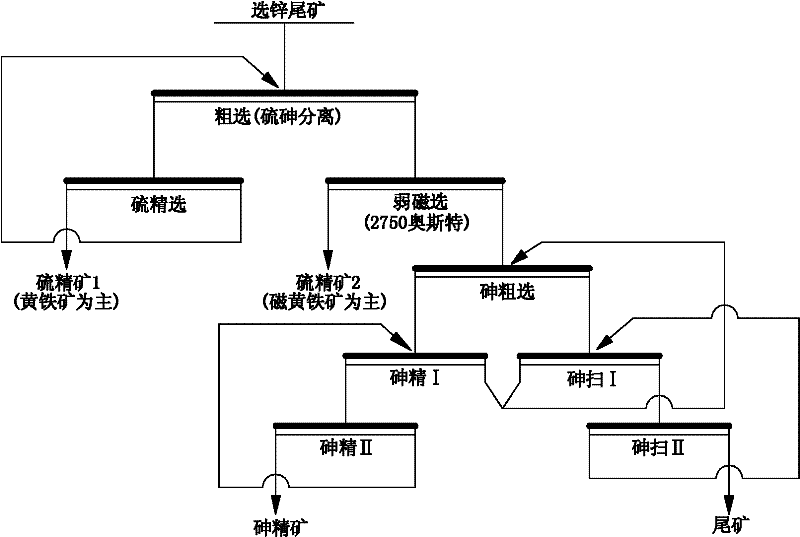

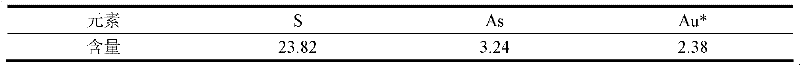

[0034] Adopt the method of the present invention to carry out sulfur, arsenic separation test research on the tailings of a gold-lead-zinc polymetallic mine in Tongling, Anhui Province, the sulfur and arsenic minerals contained in the tailings are pyrrhotite, pyrite and arsenopyrite, and the others are Some gangue minerals such as carbonate and quartz etc. Among the three minerals, pyrrhotite has the highest content, followed by arsenopyrite and pyrite. Gold is mainly fine-grained gold, distributed in all three minerals, but higher in arsenopyrite. The specific multi-element analysis of the tailings is shown in Table 1.

[0035] Table 1 Tailings multi-element analysis results / %

[0036]

[0037] *g / t

[0038] As can be seen from the data in Table 1, the recyclable elements of the tailings are S, As, and Au. According to the properties of the raw ore, the floating-magnetic combined process of the present invention is adopted. The specific process flow is shown in figure ...

Embodiment 2

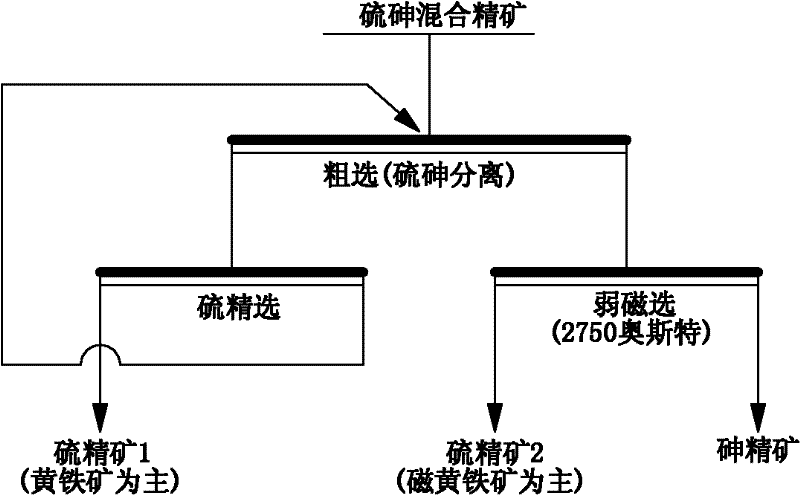

[0052] The mixed concentrate of sulfur and arsenic selected from a polymetallic mine in Tongling, Anhui has too high arsenic content to be sold as sulfur concentrate, and separation of sulfur and arsenic is required. It is proposed to use the method of the present invention to separate sulfur and arsenic to obtain qualified sulfur and arsenic. concentrates and arsenic concentrates for sale. The minerals contained in the sulfur and arsenic mixed concentrate mainly include pyrrhotite, pyrite, arsenopyrite and a small amount of gangue minerals. The specific multi-element analysis is shown in Table 3. .

[0053] Table 3 Multi-element analysis results of sulfur arsenic concentrate / %

[0054]

[0055] *g / t

[0056] From the data in Table 3, it can be seen that the recoverable elements of the tailings are S, Fe, As, and Au, and the gold is mainly fine-grained gold, which is scattered and distributed in pyrrhotite, pyrite, and arsenopyrite. , but its content is higher in arsenop...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Magnetic field strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com