Artificial jade based on gangue and manufacturing method thereof

A technology of artificial jade and coal gangue, applied in sustainable waste treatment, solid waste management, climate sustainability, etc., can solve the problems of groundwater air pollution, ecological environment hazards, unstable quality, etc., and achieve good mechanical properties, texture, etc. Delicate, tough, inexpensive effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

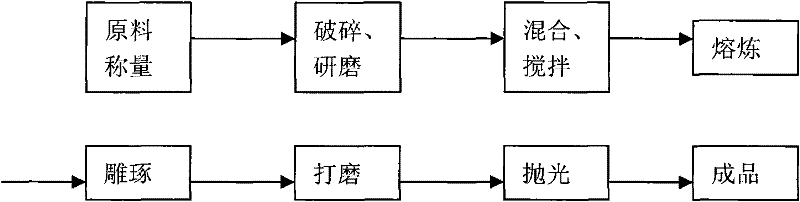

[0038] Example 1: Press figure 1 Shown, the production raw material and proportioning are:

[0039] Coal gangue: 5-85%

[0041] Aluminum Oxide or Aluminum Hydroxide: 5-15%

[0043] Soda ash: 5-25%

[0045] Borax: 10-30%

[0046] Sodium silicate: 10-30%

[0047] Calcium Oxide or Calcium Carbonate: 5-15%

[0048] Titanium dioxide: 1-5%

[0049] Potassium carbonate: 5-15%

[0050] Talc: 0-10%

[0051] Manganese dioxide: 0.2-8%

[0052] Preparation steps and process parameters are:

[0053] (1) Weigh various raw materials as required;

[0054] (2) Crushing and grinding blocky raw materials;

[0055] (3) Put various raw materials into the container and mix and stir to make the raw material components uniform;

[0056] (4) Pour the uniformly mixed raw materials into a crucible and put them into a smelting furnace for smelting. The characteristics are: put the raw materials into ...

Embodiment 2

[0059] Example 2: Press figure 1 Shown, the production raw material and proportioning are:

[0060] Coal gangue: 5-85%

[0061] Quartz powder: 25-85%

[0062] Zinc Oxide: 5-15%

[0063] Soda ash: 5-25%

[0064] Magnesium Oxide: 5-15%

[0065] Borax: 10-30%

[0066] Sodium silicate: 10-30%

[0067] Calcium Oxide or Calcium Carbonate: 5-15%

[0068] Titanium dioxide: 1-5%

[0069] Potassium carbonate: 5-15%

[0070]Talc: 0-10%

[0071] Copper oxide: 0.2-8%

[0072] Preparation steps and process parameters are:

[0073] (1) Weigh various raw materials as required;

[0074] (2) Crushing and grinding blocky raw materials;

[0075] (3) Put various raw materials into the container and mix and stir to make the raw material components uniform;

[0076] (4) Pour the uniformly mixed raw materials into a crucible and put them into a smelting furnace for smelting. The characteristics are: put the raw materials into the crucible, put them into the smelting furnace at room tem...

Embodiment 3

[0079] Embodiment 3: press figure 1 Shown, the production raw material and proportioning are:

[0080] Coal gangue: 5-85%

[0081] Quartz powder: 25-85%

[0082] Aluminum Oxide or Aluminum Hydroxide: 5-15%

[0083] Zinc Oxide: 5-15%

[0084] Soda ash: 5-25%

[0085] Magnesium Oxide: 5-15%

[0086] Calcium Oxide or Calcium Carbonate: 5-15%

[0087] Titanium dioxide: 1-5%

[0088] Potassium carbonate: 5-15%

[0089] Talc: 0-10%

[0090] Ferric oxide: 0.2-8%

[0091] Manganese dioxide: 0.2-8%

[0092] Preparation steps and process parameters are:

[0093] (1) Weigh various raw materials as required;

[0094] (2) Crushing and grinding blocky raw materials;

[0095] (3) Put various raw materials into the container and mix and stir to make the raw material components uniform;

[0096] (4) Pour the uniformly mixed raw materials into a crucible and put them into a smelting furnace for smelting. The characteristics are: put the raw materials into the crucible, put them i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com