Oxygen-containing concentrated laundry powder

A concentrated washing powder, powdered technology, applied in the directions of detergent compounding agent, detergent composition, washing composition bleaching agent, etc., can solve the problems of high damage clothes and fillers, high storage and transportation packaging costs, unfavorable environmental protection and other problems , to achieve the effect of protecting a wide range of clothing, good stability and overcoming poor detergency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

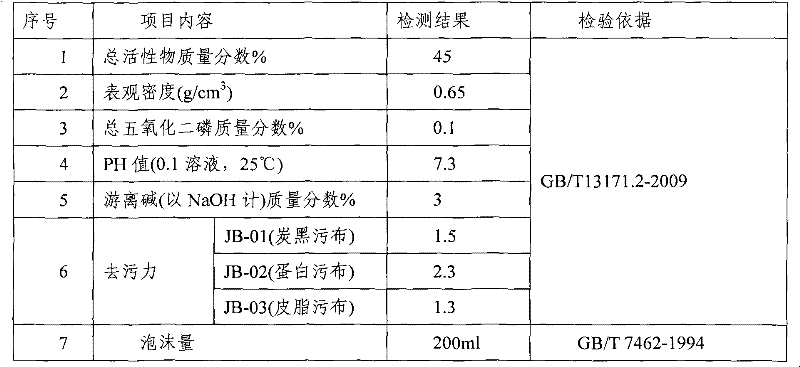

Image

Examples

Embodiment 1

[0037] Embodiment 1: a kind of oxygen-containing concentrated washing powder, its each component and mass parts thereof are:

[0038] Percarbamide 25%;

[0039] Fatty alcohol polyoxyethylene ether sodium sulfate (AES particles, activity 30%) 20%;

[0040] Sodium Lauryl Sulfate (Powder K12) 2%;

[0041] Sodium alpha olefin sulfonate (powdered AOS) 12%;

[0042] Sodium fatty acid methyl ester sulfonate (powdered MES) 1%;

[0043] Fatty alcohol polyoxyethylene (9) ether (AEO-9) 12%;

[0044] Fatty acid sodium salt 15%;

[0045] Silicone defoamer (powder) 1%;

[0046] Fluorescent whitening agent (CBS-X) 0.1%;

[0047] Ternary compound enzyme 0.3%;

[0048] Sodium Citrate 1.3%;

[0049] Bentonite 10%;

[0050] Fragrance 0.3%.

[0051] Wherein, the fluorescent whitening agent (CBS-X) is 4,4'-bistilbene derivatives; the fatty alcohol polyoxyethylene ether sodium sulfate (AES particles, activity 30%) was purchased from Weike ( Tianjin) Mining Co., Ltd.; the fatty acid sodiu...

Embodiment 2

[0052] Embodiment 2: the preparation method of the oxygen-containing concentrated washing powder described in embodiment 1:

[0053] 1) Select a solid mixing mixer, and accurately add 20% of fatty alcohol polyoxyethylene ether sodium sulfate (AES particles, activity 30%), sodium lauryl sulfate (powdered K12) according to the formula requirements (in terms of mass fraction) 2%, sodium alpha olefin sulfonate (powder AOS) 12%, sodium fatty acid methyl ester sulfonate (powder MES) 1%, fatty acid sodium salt 15%, stir and mix evenly;

[0054] 2) Heat 12 parts of fatty alcohol polyoxyethylene ether (AEO-9) to 40°C, then add 0.3% of essence, stir to make it dissolve evenly, atomize the liquid, spray it into the material system, stir to make it evenly mixed;

[0055] 3) Add 25% percarbamide, 1% powdered silicone defoamer, 0.1% whitening agent (CBS-X), 0.3% ternary compound enzyme, 1.3% sodium citrate, 10% bentonite, and stir to make it well mixed;

[0056]4) Sieve and pack to become...

Embodiment 3

[0057] Embodiment 3: a kind of oxygen-containing concentrated washing powder, its each component and mass parts thereof are:

[0058] Percarbamide 15%;

[0059] Fatty alcohol polyoxyethylene ether sodium sulfate (AES particles, activity 30%) 15%;

[0060] Sodium Lauryl Sulfate (Powder K12) 4%;

[0061] Sodium alpha olefin sulfonate (powdered AOS) 25%;

[0062] Sodium fatty acid methyl ester sulfonate (powdered MES) 3%;

[0063] Fatty alcohol polyoxyethylene (7) ether (AEO-7) 8%;

[0064] Fatty alcohol polyoxyethylene (3) ether (AEO-3) 2%;

[0065] Fatty acid sodium salt 10%;

[0066] Silicone defoamer (powder) 2%;

[0067] Fluorescent whitening agent (CBS-X) 0.1%;

[0068] Ternary compound enzyme 0.3%;

[0069] Sodium Citrate 1.3%;

[0070] Bentonite 14%;

[0071] Fragrance 0.3%.

[0072] Wherein, the fluorescent whitening agent (CBS-X) is 4,4'-bistilbene derivatives; the fatty alcohol polyoxyethylene ether sodium sulfate (AES particles, activity 30%) was purchased ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com