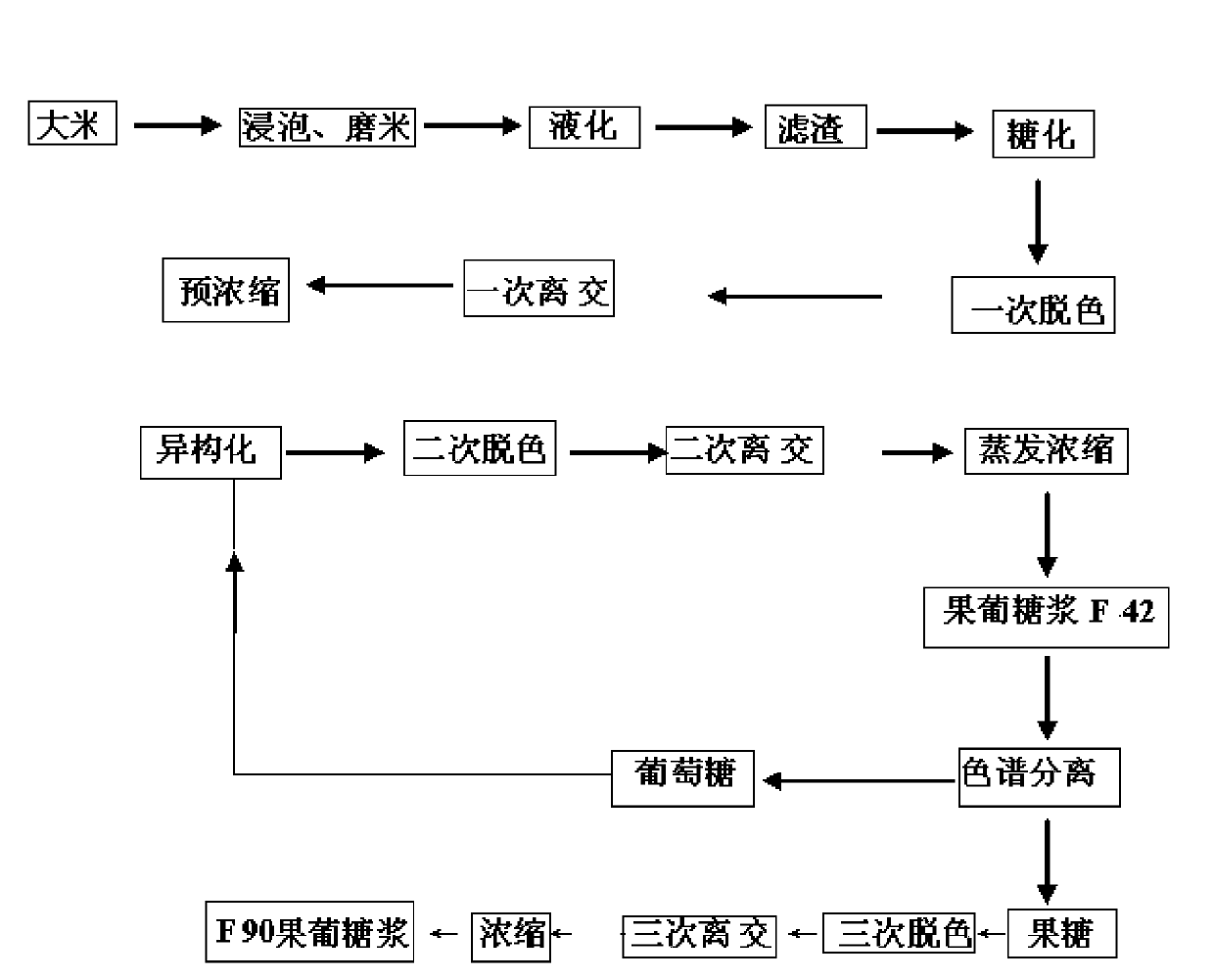

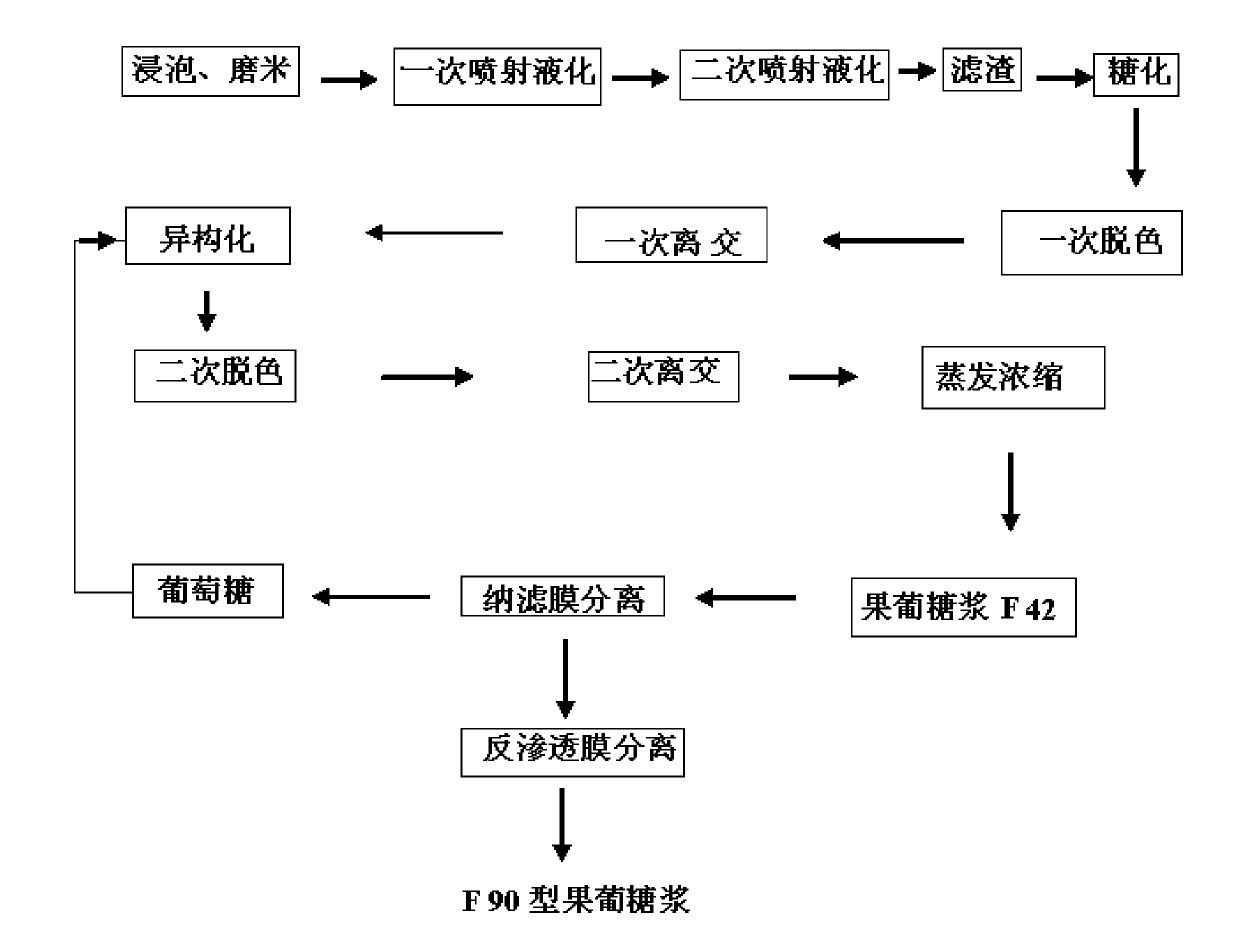

Technology for producing fructose-glucose syrup containing 90% of fructose from rice

A fructose syrup and rice technology, which is applied in the technical field of rice production with a content of 90% fructose syrup, can solve the problems of large deionized water consumption, high labor intensity, and large equipment investment, and achieve simple and compact equipment structure, The effect of reducing product ash content and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The implementation of the present invention will be described in detail below in conjunction with the accompanying drawings, but they do not constitute a limitation to the present invention, and are only examples. At the same time, the advantages of the present invention will become clearer and easier to understand.

[0026] 1. Raw and auxiliary materials

[0027] 1) Acceptance of rice: The relevant inspection standards of food hygiene standards such as GB1354-86 and GB2715-2005 are implemented for rice.

[0028] 2) Acceptance of auxiliary materials: high temperature resistant α-amylase, glucose glucoamylase, glucose isomerase, activated carbon, hydrochloric acid, liquid caustic soda, yin and yang resin, magnesium sulfate heptahydrate, etc. are accepted according to national standards.

[0029] The present invention uses rice to produce the technology of fructose syrup with a content of 90%.

[0030] 1) Soak and grind rice

[0031] a) Before starting the machine, che...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com