Method for making Tibetan paper by hand

A production method and paper storage technology, which is applied in the field of paper manufacturing, can solve the problems of cooking black liquor environmental pollution and low lignin removal efficiency, and achieve long-term preservation, improved flexibility and strength, and enhanced mildew and moth resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

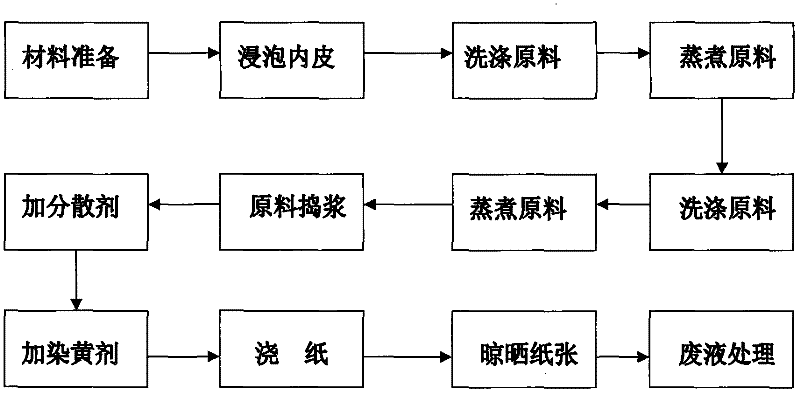

Method used

Image

Examples

Embodiment 1

[0027] Embodiment 1: Handmade Tibetan paper of the present invention is carried out by the following method.

[0028] 1. First use a wooden hammer to smash the stems and roots of Rhizoma daphnis to separate the skin from the inner stems. Use a knife to remove the black outer skin and wooden inner tendons of the stems and roots to obtain the inner skin fibrous tissue, and dry it for later use.

[0029] 2. Put the stems of Daphne daphne and the inner skin of chamaejasma root into a clear water pool, soak for 2-5 days depending on the temperature, until they become soft, and then rinse.

[0030] 3. Take about 50 grams of dry rhizomes of Coptidis Rhizome of Ranunculaceae plant per liter of water, wash, chop, soak in water for 24 hours, then heat and boil for 15 minutes, cool and stand for 2 hours, and then heat for 20-30 minutes , after cooling, gauze filter for later use.

[0031] 4. After pricking, washing, pulverizing and beating the cactus, centrifuge to get the juice, and fi...

Embodiment 2

[0040] Embodiment 2: also can prepare by following method.

[0041] 1. First use a wooden hammer to smash the stems and roots of Rhizoma daphnis to separate the skin from the inner stems. Use a knife to remove the black outer skin and wooden inner tendons of the stems and roots to obtain the inner skin fibrous tissue, and dry it for later use.

[0042]2. Put the stems of Daphne daphne and the inner skin of chamaejasma root into a clear water pool, soak for 2-5 days depending on the temperature, until they become soft, and then rinse.

[0043] 3. Take about 100 grams of dry rhizome of Coptidis Rhizome of Ranunculaceae plant per liter of water, wash, chop, soak in water for 24 hours, then heat and boil for 15 minutes, cool and stand for 2 hours, and then heat for 20-30 minutes , after cooling, gauze filter for later use.

[0044] 4. After pricking, washing, pulverizing and beating the cactus, centrifuge to get the juice, and filter it for later use.

[0045] 5. Mix 8 parts of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com