Heat conducting oil smoke residual heat recovery method

A recovery method and flue gas waste heat technology, which is applied in the field of flue gas waste heat utilization, can solve problems such as insufficient utilization of flue gas waste heat, uneconomical pressure in the water heat medium system, and increased loss of effective energy, so as to avoid dew point corrosion. , low pressure resistance requirements and equipment anti-corrosion requirements, and the effect of improving thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

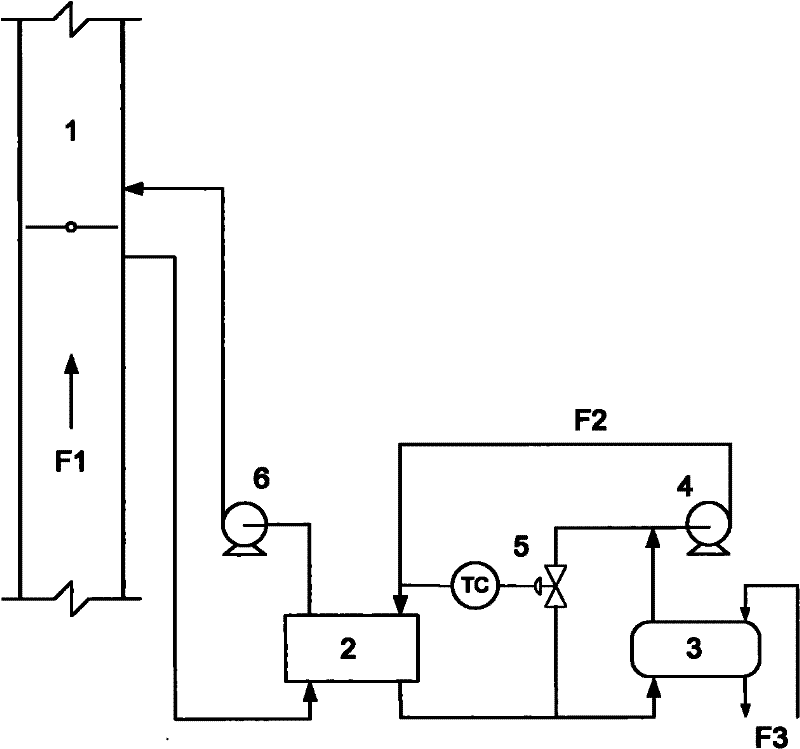

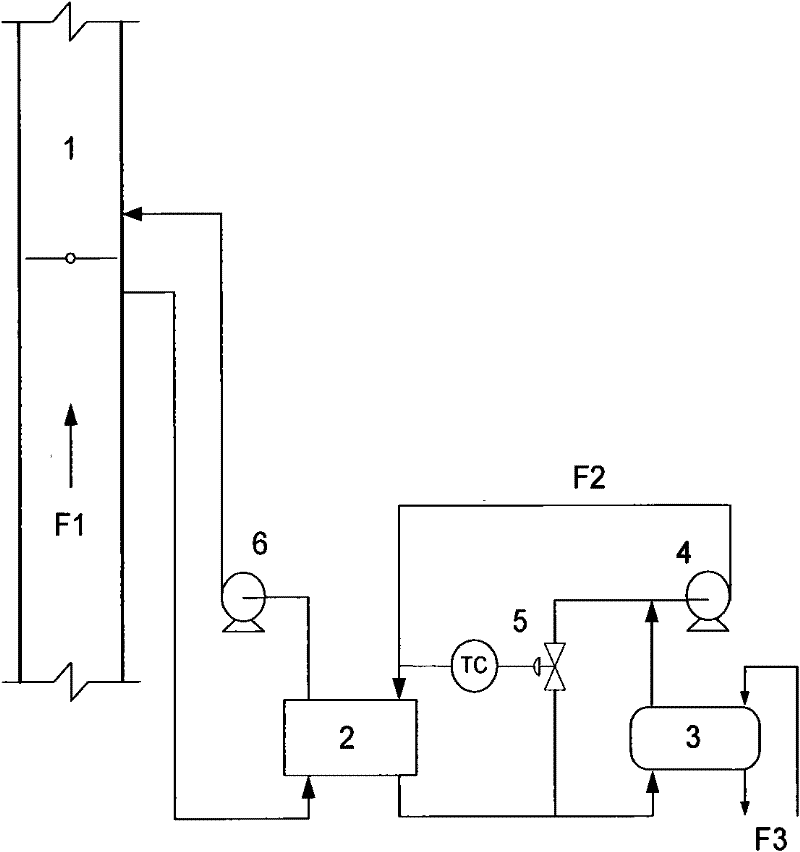

[0035] Process of the present invention see figure 1 . The process is described as follows: use the induced draft fan 6 to guide the flue gas F1 below the inner baffle of the flue 1 to the flue gas-heat transfer oil heat exchanger 2, exchange heat with the heat transfer oil F2, and return it to the upper side of the flue baffle through the induced draft fan to discharge . The flue gas-heat transfer oil heat exchanger 2 is a tubular heat exchanger, the flue gas goes through the shell side, and the heat transfer oil goes through the tube side. The heat transfer oil inlet temperature of the flue gas-heat transfer oil heat exchanger 2 is measured by a thermocouple, and the signal is sent to the bypass flow control valve 5 . The heat transfer oil is divided into two paths from the flue gas-heat transfer oil heat exchanger 2, one of which enters the air preheater 3 to exchange heat with the heating furnace air F3, and after the heat exchange, it is connected to the bypass control...

Embodiment 2

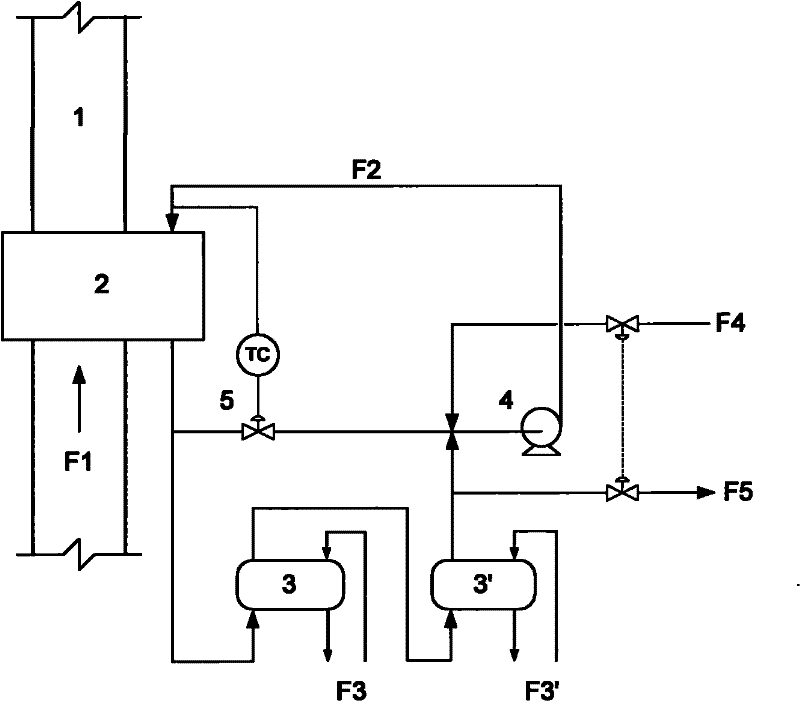

[0038] Process of the present invention see figure 2 . The process is described as follows: the flue gas-heat transfer oil heat exchanger 2 is installed in the flue 1, which is a plate heat exchanger, and the hot flue gas F1 exchanges heat with the heat transfer oil in the flue gas-heat transfer oil heat exchanger 2, and conducts heat The oil is hydrogenated tail oil. After the heat transfer oil passes through the flue gas-heat transfer oil heat exchanger 2, the temperature rises, and the high-temperature heat transfer oil is divided into two strands, and one strand enters the working medium heating area as a heat source, and is used to heat various low-temperature working medium 1F3 and working medium 2F3'. After heating, the temperature decreases and turns into low-temperature heat transfer oil. A part of the low-temperature heat transfer oil leaves the circulation, and the heat transfer oil F5 removed from the cycle enters the next step of the oil treatment process. The h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com