Dye sensitized solar cell with metal line layer and electrodes thereof

A solar cell and dye-sensitized technology, which is applied in the field of metal wire layers of electrodes, can solve problems such as unsatisfactory, time-consuming and labor-intensive, and limit the use of dye-sensitized solar cells, and achieve the effect of reducing the impedance value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Embodiment 1: Preparation of a working electrode with a metal wire layer of the present invention

[0043] [preparation]

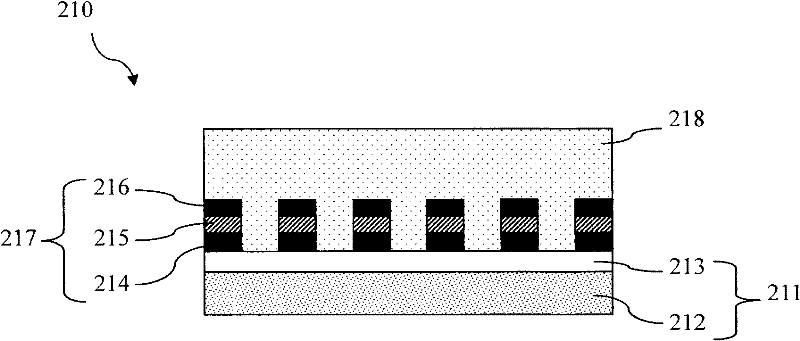

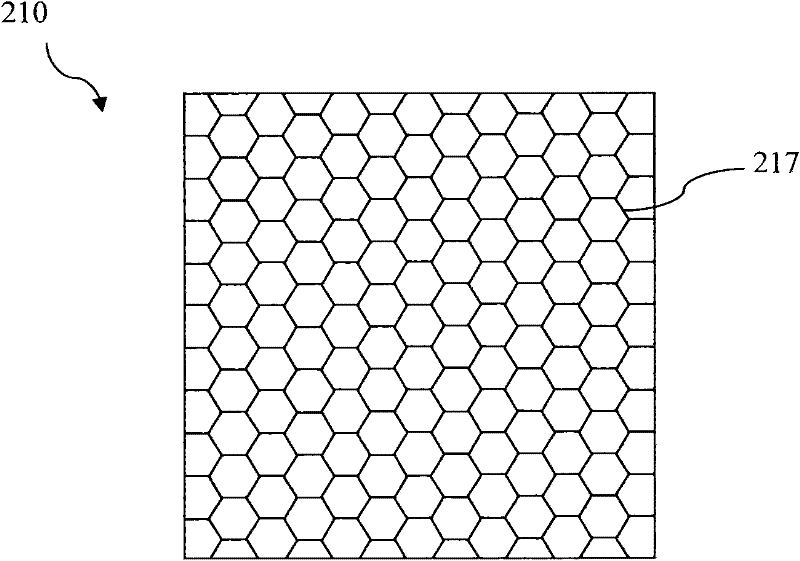

[0044] see Figure 2A , choose glass as the substrate 212 of the conductive substrate 211 of the working electrode (anode) 210 in this embodiment, and fluorine-doped tin oxide (FTO, Fluorine-Doped Oxide) is deposited on the substrate by chemical vapor deposition (CVD) A conductive layer 213 is formed on the surface. implanting nickel metal on the aforementioned conductive layer 213 by vapor deposition to form the first nickel wire layer 214, and then implanting aluminum metal on the aforementioned first nickel wire layer 214 by vapor deposition, An aluminum wire layer 215 is formed, and finally nickel metal is implanted on the aluminum wire layer 215 by evaporation to form a second nickel wire layer 216 . The aforementioned first nickel wire layer 214, aluminum wire layer 215 and second nickel wire layer 216 together constitute the metal wire lay...

Embodiment 2

[0051] Embodiment 2: Preparation of the counter electrode with the metal wire layer of the present invention

[0052] see Figure 3A Select flexible polyethylene naphthalate (PEN) as the substrate 312 of the conductive substrate 311 of the working electrode (anode) 310 in this embodiment, and indium tin oxide (ITO, Indium Tin Oxide) A conductive layer 313 is formed on the surface of the substrate by sputtering. Then titanium metal is implanted on the aforementioned conductive layer 313 by evaporation to form the metal line layer 314 of this embodiment. The shape of the aforementioned metal line layer 314 is as follows Figure 3B As shown, they are parallel lines to maintain good light transmittance of the counter electrode (cathode) 310 .

[0053] Then, a platinum layer is covered on the surface of the conductive layer 313 provided with the metal wire layer 314 by vacuum coating as a catalyst layer 315 (thickness is 1 nm), and the counter electrode (cathode) 310 of this emb...

Embodiment 3

[0054] Embodiment 3: Preparation of the electrochemical device of the present invention

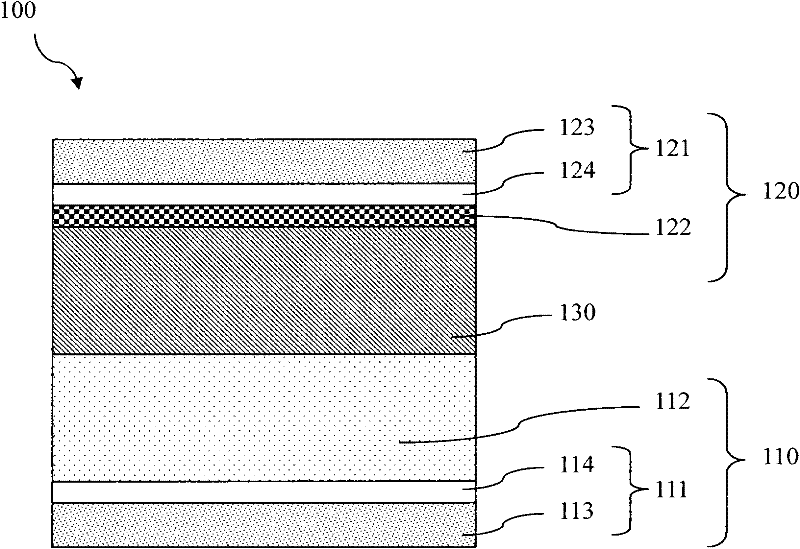

[0055] see Figure 4 , taking the dye-sensitized solar cell 400 as an example of the electrochemical device of this embodiment, the structure of each layer is described as follows:

[0056] A flexible titanium plate (Ti) is selected as the conductive substrate 411 of the working electrode (anode) 410 of this embodiment, and then titanium dioxide nanoparticles (TiO 2 ) coated on it to make TiO with a thickness of about 15 μm 2 / Ti electrode. Then the aforementioned TiO 2 After the / Ti photoelectrode was cut into an area of 8 cm x 8 cm (length x width), it was placed in an electric furnace and sintered at 500 ° C for 30 minutes to strengthen the connection force between titanium dioxide nanoparticles. Then at room temperature, the TiO 2 / Ti photoelectrode soaked in 0.3mmol / L photoexcitable dye solution (dissolve 0.036 g of N719 dye in 100 ml of tert-butanol and acetonitrile mixture, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com