Novel cathode material of vanadium oxide nanometer lithium ion battery and preparation method thereof

A lithium-ion battery and cathode material technology, which is applied in the direction of battery electrodes, circuits, electrical components, etc., can solve problems such as not found, and achieve the effects of improving conductivity, simple operation, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

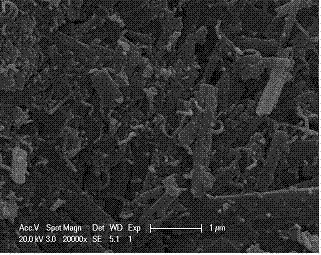

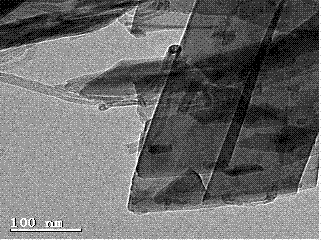

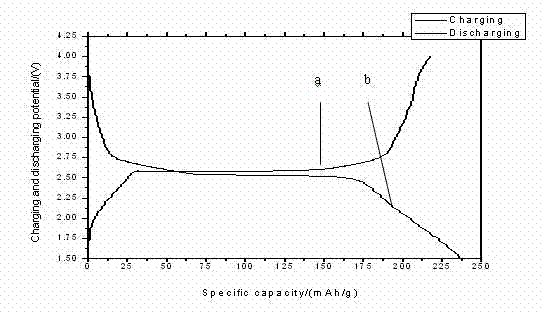

Image

Examples

Embodiment 1

[0026] Embodiment 1: a kind of preparation method of lithium battery cathode material, comprises the following steps,

[0027] 1. Preparation of Vanadium Oxysol

[0028] Vanadyl sol was prepared by sol-gel method, and 1gV 2 o 5 The powder and hydrogen peroxide (30% concentration) are mixed at a mass / volume ratio of 1:30 (g / ml), stirred magnetically in a water bath at 5°C, and will be accompanied by violent oxygen and heat release shortly thereafter. The whole process takes about 1 hour . Finally, an orange-red vanadium oxysol is generated.

[0029] 2. Dispersion of carbon nanotubes

[0030] Take 1 g of original carbon nanotubes and add them into 50 mL of concentrated sulfuric acid / concentrated nitric acid with a volume ratio of 5:1, and react for 1 hour. After cooling, centrifuge at 1000 rpm for 10 minutes to remove the mixed acid in the upper layer, then filter and wash until neutral.

[0031] 3. Preparation of colloidal suspension

[0032] The prepared vanadyl sol was...

Embodiment 2

[0041] 1. Preparation of Vanadium Oxysol

[0042] Vanadyl sol was prepared by sol-gel method, and 1gV 2 o 3 The powder and hydrogen peroxide (30% concentration) are mixed at a mass / volume ratio of 1:20 (g / ml), stirred magnetically in a water bath at 5°C, and will be accompanied by violent oxygen and heat release shortly thereafter. The whole process takes about 1 hour . Finally, an orange-red vanadium oxysol is generated.

[0043] 2. Dispersion of carbon nanotubes

[0044] 1 g of original carbon nanotubes was added into 50 mL of concentrated sulfuric acid / concentrated nitric acid with a volume ratio of 7:1, and reacted for 1 hour. After cooling, centrifuge at 1000 rpm for 10 minutes to remove the mixed acid in the upper layer, then filter and wash until neutral.

[0045] 3. Preparation of colloidal suspension

[0046] The prepared vanadyl sol was mixed with 0.2 g of dispersed carbon tubes and magnetically stirred for ~1 hour until a black colloidal suspension was formed....

Embodiment 3

[0055] 1. Preparation of Vanadium Oxysol

[0056] Prepare vanadium oxysol by sol-gel method, mix 1g of vanadium powder and hydrogen peroxide (30% concentration) at a mass / volume ratio of 1:40 (g / ml), stir magnetically in a water bath at 5°C, and soon thereafter With intense oxygen and heat release, the whole process takes about 1 hour. Finally, an orange-red vanadium oxysol is generated.

[0057] 2. Dispersion of carbon nanotubes

[0058] Take 1g of original carbon nanotubes and add 100mL60 o C in water, magnetically stirred for 2 days, then filtered and washed to neutral.

[0059] 3. Preparation of colloidal suspension

[0060] The prepared vanadyl sol was mixed with 0.18 g of dispersed carbon tubes and magnetically stirred for ~1 hour until a black colloidal suspension was formed.

[0061] 4. Preparation of vanadium oxide nanosheets under hydrothermal conditions

[0062] The black colloidal turbid liquid was transferred into a hydrothermal reaction kettle for 2 days of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com