Starter and preparation method and use thereof

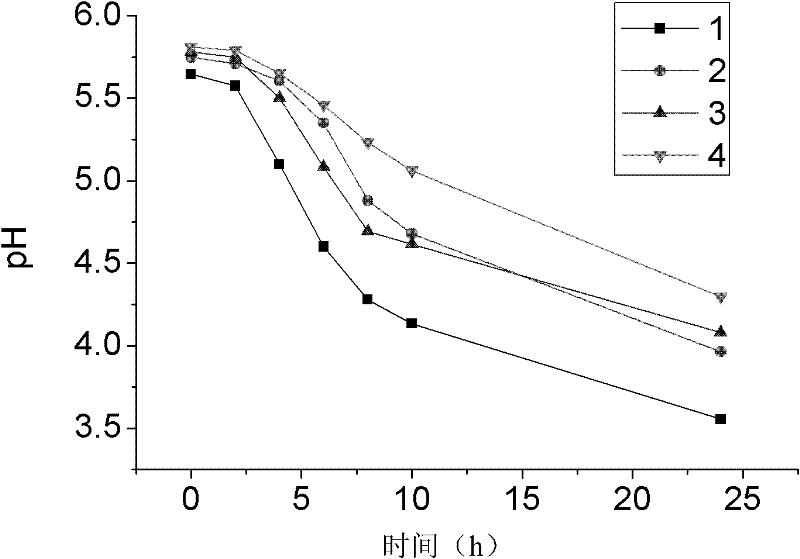

A technology of direct input starter and fermented sausage, which is applied in the field of fermentation, can solve the problems that have not yet appeared in the application of industrialization, and achieve the effects of optimizing the culture process of bacteria and freeze-drying process, high activity, and fast acid production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The preparation method of leavening agent of the present invention, its step is as follows:

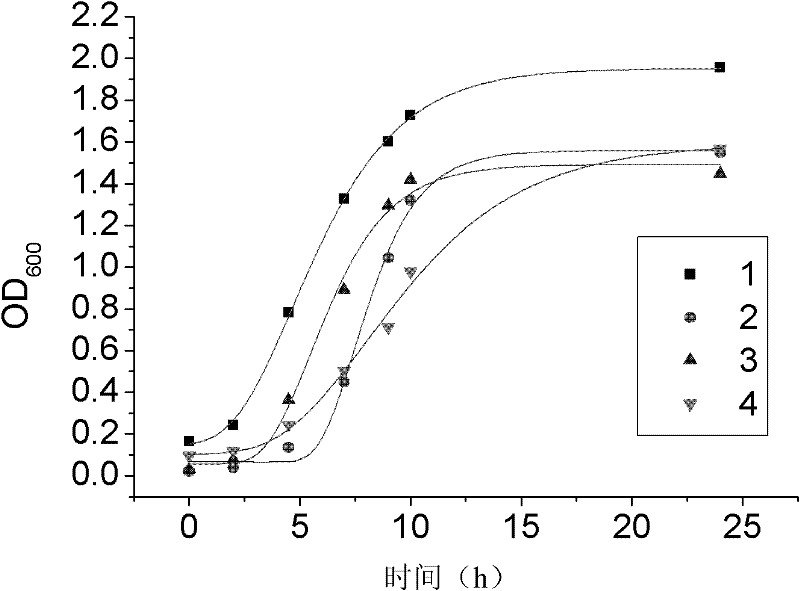

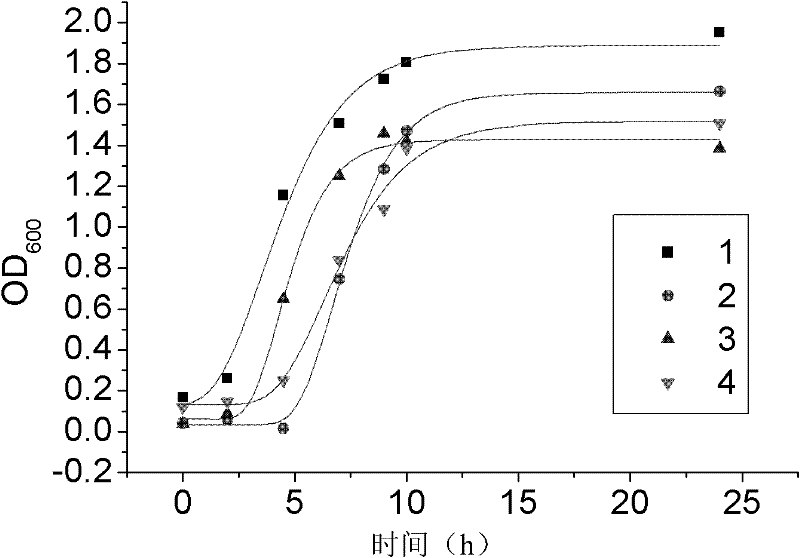

[0033] 1) Cell culture

[0034] Lactobacillus pentosus GMCC No.2313 seed solution was inoculated into the improved MRS medium at a 1% inoculation amount for batch culture, and cultured at 30°C for 10 hours at a speed of 300r / min; then the temperature was adjusted to 40°C and the speed of 300r / min Min continue to cultivate for 3h, the 40°C high temperature culture process can induce the heat resistance of the bacteria; control pH 6.5 during the above culture process;

[0035] Among them, the proportion of the above-mentioned MRS medium is that 1 liter of medium contains: glucose 22g, peptone 4g, beef extract 6g, yeast extract 5g, dipotassium hydrogen phosphate 2g, diammonium hydrogen citrate 2g, sodium acetate 2g, Magnesium sulfate 0.4g, manganese sulfate 0.1g, Tween 1ml, the balance is water, pH6.5.

[0036] 2) Collect bacteria

[0037]Centrifuge the culture solution obtaine...

Embodiment 2

[0042] The preparation method of leavening agent of the present invention, its step is as follows:

[0043] 1) Cell culture

[0044] Lactobacillus pentosus GMCC No.2313 seed liquid was inoculated into the improved MRS medium according to the inoculation amount of 0.5% for batch culture; the initial pH of the medium was 6.5, and then the pH was controlled to 7.0, and the rotation speed was 250r / min; the culture stage 1 The temperature of the stage 2 was 32°C, and the incubation time was 11 hours; the temperature of the stage 2 was 35°C, and the incubation time was 4 hours;

[0045] Among them, the proportion of the above-mentioned MRS medium is that 1 liter of medium contains: 24g of glucose, 3g of peptone, 8g of beef extract, 7g of yeast extract, 2g of dipotassium hydrogen phosphate, 2g of diammonium hydrogen citrate, 2g of sodium acetate, Magnesium sulfate 0.5g, manganese sulfate 0.2g, Tween 1ml, balance water, pH 6.5.

[0046] 2) Collect bacteria

[0047] Centrifuge the c...

Embodiment 3

[0052] The preparation method of leavening agent of the present invention, its step is as follows:

[0053] 1) Cell culture

[0054] Lactobacillus pentosus GMCC No.2313 seed solution was inoculated into the improved MRS medium according to the inoculation amount of 0.1% for batch culture; the initial pH of the medium was 7.0, and then the pH was controlled to 7.0, and the rotation speed was 200r / min; The temperature is 33°C, and the incubation time is 12h; the temperature of the cultivation stage 2 is 38°C, and the incubation time is 2h;

[0055] Wherein, the proportion of the above-mentioned MRS medium is that 1 liter of medium contains: 20 g of glucose, 2 g of peptone, 4 g of beef extract, 3 g of yeast extract, 2 g of dipotassium hydrogen phosphate, 2 g of diammonium hydrogen citrate, 2 g of sodium acetate, Magnesium sulfate 0.6g, manganese sulfate 0.3g, Tween 1ml, balance water, pH 6.5.

[0056] 2) Collect bacteria

[0057] Centrifuge the culture solution obtained from t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com