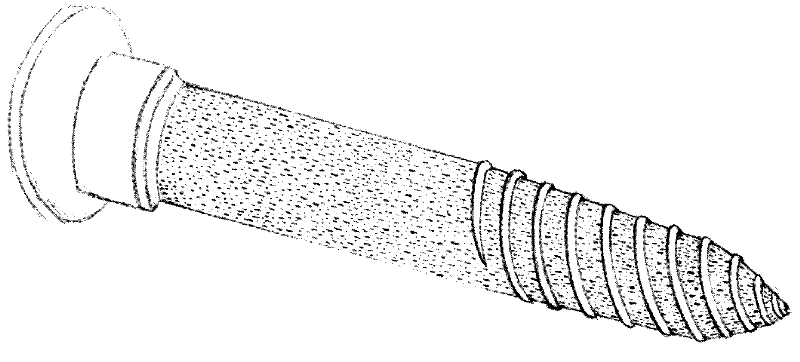

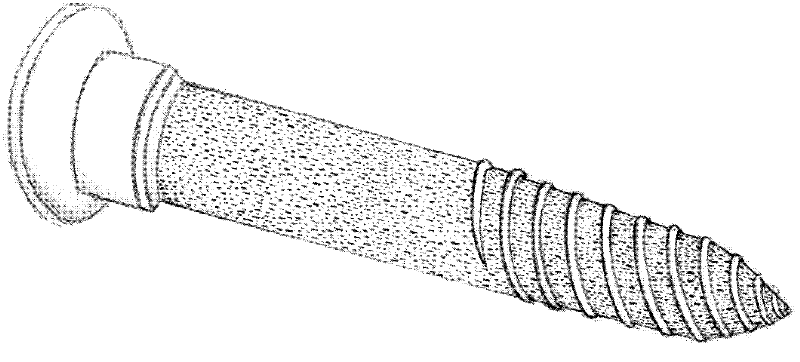

Degradable fiber-enhanced polycaprolactone degradable bone nail and preparation method thereof through solution method

A technology of polycaprolactone and degradable fiber, which is applied in the fields of medical science and surgery, can solve the problems of low breaking strength and easy fatigue, and achieve the effects of good compatibility, pain relief and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A polycaprolactone (PCL) degradable bone nail reinforced with degradable fibers, the bone nail is a nail-like object, comprising: degradable fibers and PCL resin; wherein the weight ratio of the degradable fibers in the bone nail It is 20%; the degradable fiber dispersed in the bone nail plays the role of strengthening and toughening, while the PCL resin plays the role of the bone nail matrix.

[0030] The preparation includes: (1) Take some PLA slices and dry them under vacuum at 150°C for 5 hours; then extrude them in a melt spinning machine to obtain PLA primary single fibers; The diameter is 0.05 mm; the fibers are cut into staple fibers with an average length of 8 mm long.

[0031] (2) Weigh 98 g of PCL and 2 g of TBC with a balance, and put PCL and TBC into 50 ml of ethyl acetate for dissolution to obtain a PCL solution.

[0032] (3) Put PLA short fibers into PCL solution, the weight ratio of fiber to PCL is PLA:PCL=10:100, and stir evenly.

[0033] (4) Cast the...

Embodiment 2

[0036] (1) Take a number of PGA slices and dry them under vacuum at 120°C for 6 hours; then extrude them in a melt spinning machine to obtain PGA primary single fibers; after stretching, obtain PGA stretched fibers with a single filament diameter of 0.08 mm; the fibers were cut into staple fibers with an average length of 10 mm long.

[0037] (2) Weigh 98 g of PCL and 2 g of dodecyl methacrylate with a balance, and put PCL and dodecyl methacrylate into 50 ml of ethyl acetate for dissolution to obtain a PCL solution.

[0038] (3) Put the PGA short fiber into the PCL solution, the weight ratio of the fiber to the PCL is PLA:PCL=15:100, and stir evenly.

[0039] (4) Cast the PCL solution mixed with PGA short fibers into a cylindrical mold several times, and vacuumize to remove the solvent; after the casting is completed, put the mold into an oven after the solvent is basically removed, and set it at 45°C for 1 hour Allow the compound to cure.

[0040] (5) Take out the PGA fiber...

Embodiment 3

[0042] (1) Take a number of PGLA slices and dry them under vacuum at 120°C for 6 hours; then extrude them in a melt spinning machine to obtain PGLA primary fiber bundles, each bundle of fibers has 8 single fibers; after stretching, PGLA fibers are obtained. Stretch the fiber bundle, and its single fiber diameter is 0.03mm; Preserve the fiber bundle in the state of long filament bundle.

[0043] (2) Weigh 98 g of PCL and 2 g of myristyl methacrylate with a balance, and put PCL and myristyl methacrylate into 50 ml of ethyl acetate for dissolution to obtain a PCL solution.

[0044] (3) Arrange the PGLA fiber bundles neatly in the mold so that the axial direction of the fiber bundles is parallel to the central axis of the cylindrical mold, and the weight ratio of the fibers to PCL is PGLA:PCL=20:100.

[0045] (4) Cast the PCL solution into a cylindrical mold several times, and remove the solvent by vacuuming; after the casting is completed, the mold is put into an oven after the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com