Three-layer multi-metal oxide catalyst and preparation method thereof

A technology of multi-metal oxides and catalysts, applied in metal/metal oxide/metal hydroxide catalysts, catalyst activation/preparation, preparation of carbon-based compounds, etc., can solve the problem of high initial catalyst activity, permanent reduction in reaction activity, Reduce catalyst utilization and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

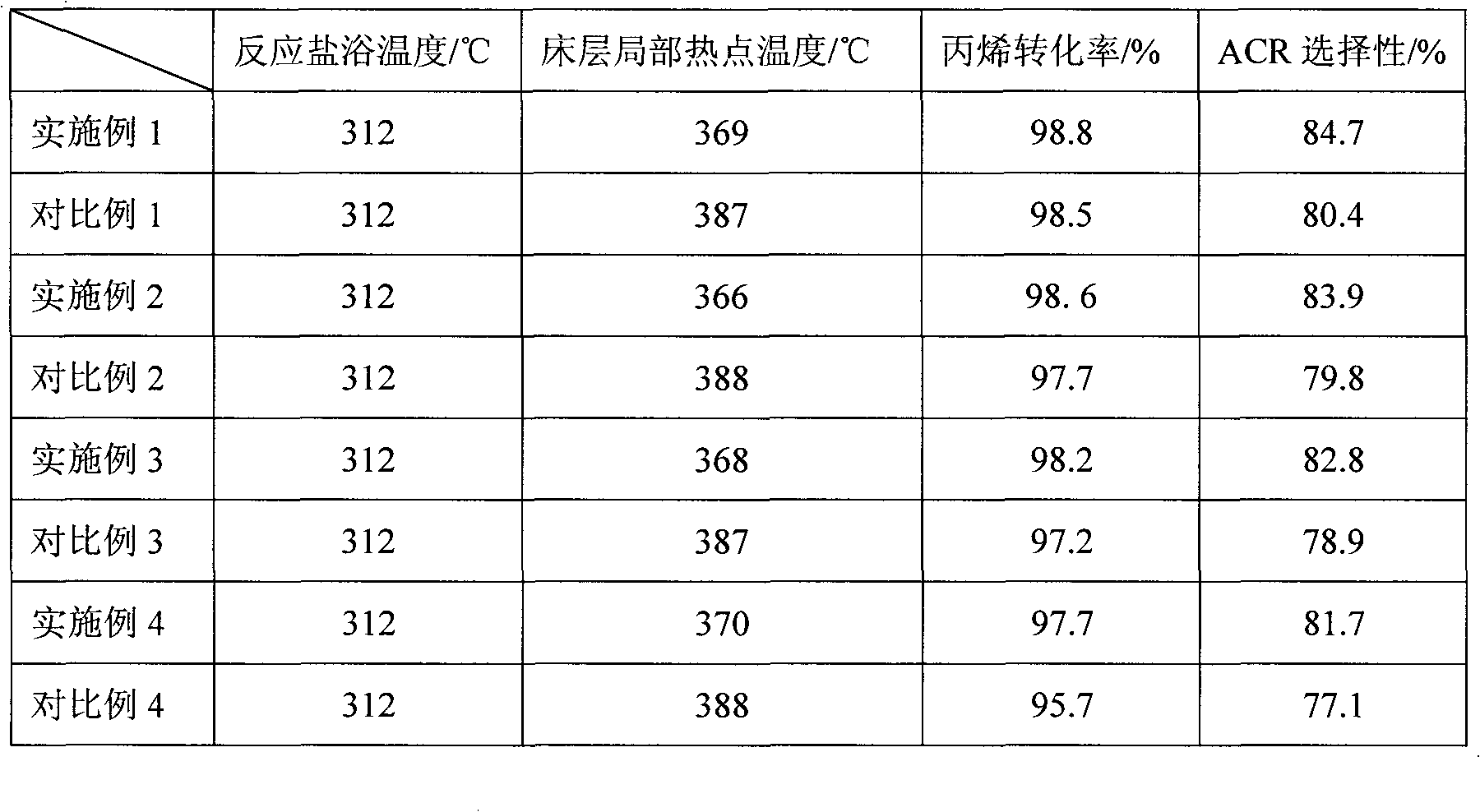

Embodiment 1

[0036] Preparation of Catalyst 1

[0037] The first step: preparation of catalyst inner layer matrix

[0038] (1) Preparation of active component slurry (a)

[0039] Under stirring conditions, 123.6 grams of ammonium molybdate, 24.9 grams of nickel acetate and 14.56 grams of cobalt nitrate were dissolved in 500 ml of pure water (water temperature above 65°C) to obtain a slurry (1), and then 145.3 grams of bismuth nitrate was dissolved in dilute nitric acid , to obtain solution (2). Then, the slurry (2) is mixed with the slurry (1), and then 30 grams of silicon oxide powder is added to obtain the slurry (3), and vigorously stirred for co-precipitation reaction to obtain the active component slurry (a).

[0040] (2) Preparation of auxiliary material slurry (b)

[0041] Under heating and stirring, 2.53 grams of potassium nitrate, 36.9 grams of magnesium nitrate, 46.52 grams of copper nitrate and 3.8 grams of ammonium chromate were dissolved in 250 ml of pure water, and vigorou...

Embodiment 2

[0053] Preparation of Catalyst 2

[0054] The first step: preparation of catalyst inner layer matrix

[0055] (1) Preparation of active component slurry (a)

[0056] Under stirring conditions, 97 grams of ammonium molybdate, 58.2 grams of nickel nitrate and 29.1 grams of cobalt nitrate were dissolved in 500 ml of pure water (water temperature above 65°C) to obtain a slurry (1), and then 169.8 grams of bismuth nitrate was dissolved in dilute nitric acid , to obtain slurry (2). Then, the slurry (2) was mixed with the slurry (1), and then 21 grams of silicon oxide powder was added to obtain the slurry (3), and vigorously stirred for co-precipitation reaction to obtain the active component slurry (a).

[0057] (2) Preparation of auxiliary material slurry (b)

[0058] Under heating and stirring, 20.2 grams of potassium nitrate, 60.6 grams of ferric nitrate and 6.2 grams of boric acid were dissolved in 250 ml of pure water, vigorously stirred and mixed uniformly to obtain catalys...

Embodiment 3

[0070] Preparation of Catalyst 3

[0071] The first step: preparation of the catalyst inner layer matrix

[0072] (1) Preparation of active component slurry (a)

[0073] The preparation of the active component slurry (a) is the same as that of catalyst 1. Take 105.9 grams of ammonium molybdate, 37.3 grams of nickel acetate, 43.7 grams of cobalt nitrate, 194 grams of bismuth nitrate and 18 grams of silicon oxide powder, and other conditions remain unchanged.

[0074] (2) Preparation of auxiliary material slurry (b)

[0075] The preparation of auxiliary material slurry (b) is the same as catalyst 1, 10.6 grams of strontium nitrate, 9.9 grams of potassium manganate and 21 grams of sodium nitrate are taken, and other conditions remain unchanged.

[0076] (3) Preparation of catalyst inner layer matrix

[0077] The preparation of the catalyst inner layer matrix is the same as catalyst 1, and the composition of the catalyst inner layer matrix is Mo 12 Bi 8 Ni 3 co 3 Si 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com