Preparation method of organosilicon powder waterproofing agent

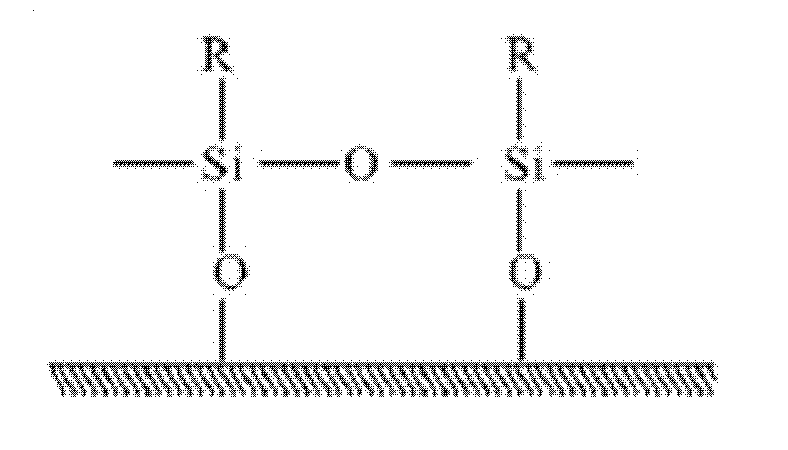

A technology of organosilicon powder and water repellent, which is applied in the chemical field to achieve the effects of good workability, excellent hydrophobicity and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

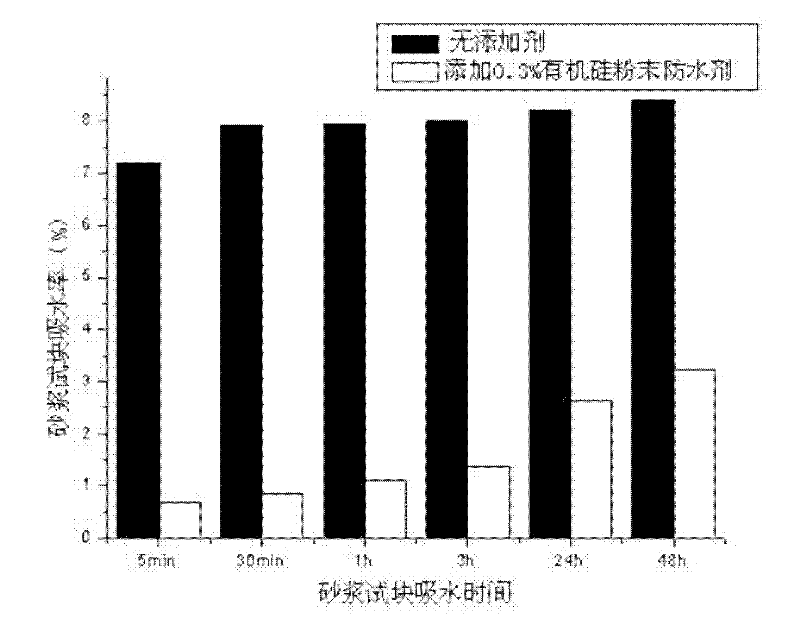

Examples

Embodiment 1

[0043] (1) Dissolve the film-forming substance polyvinyl alcohol powder in water at room temperature, and add it into the water while stirring. If the dissolution is not complete, heat it to 50°C, preferably 70°C, and the dissolution time is about 30min, then cool to At room temperature, it remains in a solution state with a mass fraction of 3%.

[0044] (2) The nano-calcium carbonate is prepared into ethanol suspension, and the mass ratio of calcium carbonate and ethanol is 1:2.

[0045] Mix the nano-calcium carbonate carrier and the octyltriethoxysilane waterproofing agent to form a uniform binary dispersion, wherein the quality of the nano-calcium carbonate is 8% of the mass of the octyltriethoxysilane waterproofing agent, and the stirring speed is 600r / min , stirring time 30min.

[0046] (3) Add a polyvinyl alcohol aqueous solution with a mass fraction of 3% to the binary dispersion of the nanometer calcium carbonate carrier-octyltriethoxysilane high-efficiency waterproof...

Embodiment 2

[0052] (1) Dissolve the film-forming substance polyvinyl alcohol powder in water at room temperature, and add it into the water while stirring. If the dissolution is not complete, heat it to 50°C, preferably 70°C, and the dissolution time is about 30min, then cool to At room temperature, it remains in a solution state with a mass fraction of 5%.

[0053] (2) The nano-calcium carbonate is prepared into ethanol suspension, and the mass ratio of calcium carbonate and ethanol is 1:3.

[0054] Mix the nano-calcium carbonate carrier and the polydimethylsiloxane waterproofing agent to form a uniform binary dispersion, wherein the quality of the nano-calcium carbonate is 15% of the mass of the polydimethylsiloxane waterproofing agent, and the stirring speed is 900r / min , stirring time 45min.

[0055] (3) Add polyvinyl alcohol aqueous solution with a mass fraction of 5% to the binary dispersion of nano calcium carbonate carrier-polydimethylsiloxane high-efficiency waterproofing agent,...

Embodiment 3

[0060] (1) Dissolving the film-forming substance hydroxyethyl cellulose in water at room temperature, and adding it into the water while stirring, the dissolution time is more than 20 minutes, and the mass fraction is 5%.

[0061] (2) Mix the nano-silica carrier with octyltriethoxysilane-polydimethylsiloxane composite high-efficiency waterproofing agent to form a uniform binary dispersion, in which octyltriethoxysilane and polydimethylsiloxane The base siloxane is compounded according to the ratio of 97:3, the nano-silica is 18% of the mass of the waterproofing agent, the stirring speed is 1500r / min, and the stirring time is 1h.

[0062] (3) the hydroxyethyl cellulose aqueous solution that mass fraction is 5% is added in the binary dispersion of nano-silica carrier-octyltriethoxysilane and polydimethylsiloxane composite waterproofing agent, and Stir to form a homogeneous ternary dispersion of hydroxyethyl cellulose film-forming material-nano-silica carrier-octyltriethoxysilane...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com