Nitrogen-doped aramid-based enhanced multistage hole carbon fiber preparation method

A technology of nitrogen doping and carbon fiber, which is applied in the fields of fiber chemical characteristics, rayon manufacturing, textiles and paper making, etc. It can solve the problems of unsatisfactory mechanical strength and achieve the goal of improving electromagnetic wave adsorption performance, strong controllability and improving mechanical strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

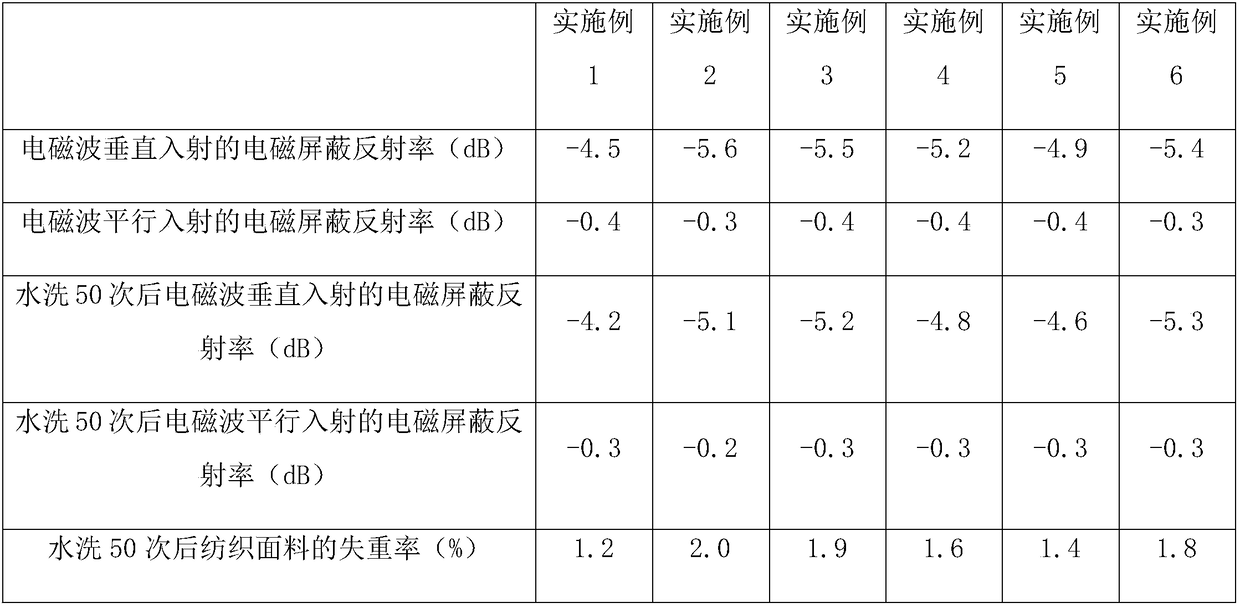

Examples

Embodiment 1

[0024] (1) Add ferric citrate to Kevlar's aramid pulp and mix it evenly to form a spinning solution, where the content of metal citrate in the spinning solution is 1wt%, and the spinning solution is transferred to the static In the injector of the spinning device, the spinning voltage is 20kV, the inner diameter of the spinneret is 0.5mm, the flow rate of the spinning solution is 0.1mL / h, the spinning distance is 10cm, the collecting roller speed is 5m / min, and the spinneret is transverse. The moving speed is 10cm / min, and the aramid fiber containing metal citrate is formed by electrostatic spinning.

[0025] (2) Put the as-spun aramid fiber containing citrate metal salt in an oxygen atmosphere, perform pre-oxidation treatment at 220°C for 5 minutes, and place it in an atmosphere containing 50% ammonia gas, and carbonize it at 1000°C for 10 minutes , To obtain nitrogen-doped aramid-based porous carbon fiber.

[0026] (3) According to the solid-liquid ratio of 1g:25mL, the nitrogen...

Embodiment 2

[0028] (1) Add nickel citrate, copper citrate and zinc citrate with a mass ratio of 1:1:1 to Kevlar’s aramid pulp, and mix them evenly to form a spinning solution. Among them, the spinning solution The content of metal citrate is 10wt%. The spinning solution is transferred to the syringe of the electrospinning device. The spinning voltage is 30kV, the spinneret inner diameter is 0.8mm, and the spinning solution flow rate is 0.6mL / h. The silk distance is 15cm, the speed of the collecting roller is 8m / min, the spinneret's lateral movement speed is 25cm / min, and the aramid fiber containing citrate metal salt is prepared by electrostatic spinning.

[0029] (2) Put the as-spun aramid fiber containing citrate metal salt in an oxygen atmosphere, perform a pre-oxidation treatment at 300°C for 10 minutes, place it in an atmosphere containing 80% ammonia, and carbonize it at 1500°C for 30 minutes , To obtain nitrogen-doped aramid-based porous carbon fiber.

[0030] (3) According to the so...

Embodiment 3

[0032] (1) Add aluminum citrate, sodium citrate and potassium citrate with a mass ratio of 1:1:1 to Kevlar's aramid pulp, and mix them evenly to form a spinning solution. Among them, the spinning solution The content of citrate metal salt is 5wt%, and the spinning solution is transferred to the syringe of the electrostatic spinning device. The spinning voltage is 25kV, the spinneret inner diameter is 0.6mm, and the spinning solution flow rate is 0.3mL / h. The silk distance is 12cm, the speed of the collecting roller is 6m / min, the spinneret's lateral movement speed is 15cm / min, and the aramid fiber containing citrate metal salt is prepared by electrostatic spinning.

[0033] (2) Put the as-spun aramid fiber containing citrate metal salt in an oxygen atmosphere, perform a pre-oxidation treatment at 2500°C for 6 minutes, place it in an atmosphere containing 60% ammonia, and carbonize it at 1400°C for 20 minutes , To obtain nitrogen-doped aramid-based porous carbon fiber.

[0034] (3)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com