Preparation method of styrene-maleic anhydride random copolymer

A technology of random copolymer and maleic anhydride, which is applied in the field of preparing styrene-maleic anhydride random copolymer by precipitation polymerization, can solve the problems of high toxicity of toluene, pollute the environment and the like, and achieves simple processing, simple reaction system, The effect of reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] St and MAn molar ratio 8: 2, wherein MAn 0.23g, St 1.0g; Initiator is dicumyl peroxide (DCP) 0.006g; Medium is ethyl butyrate, 7.5mL (monomer mass concentration 15% ). Heat in an oil bath, react at a temperature of 130°C under the protection of nitrogen, and take samples after the reaction for 10min, 20min, 30min, 60min, 120min, and 150min respectively to obtain the dispersion system of random copolymer of styrene and maleic anhydride , the dispersion system was centrifuged and dried to obtain a white powder of styrene-maleic acid drunk random copolymer. The polymerization yields under different reaction times were 14%, 31%, 38%, 50%, 56%, and 62%, respectively, and the MAn content in the copolymer was measured to be 35%, 32%, and 30% by acid-base titration. , 27%, 25%, 24%. The prepared copolymer of styrene and maleic anhydride is a random copolymer.

Embodiment 2

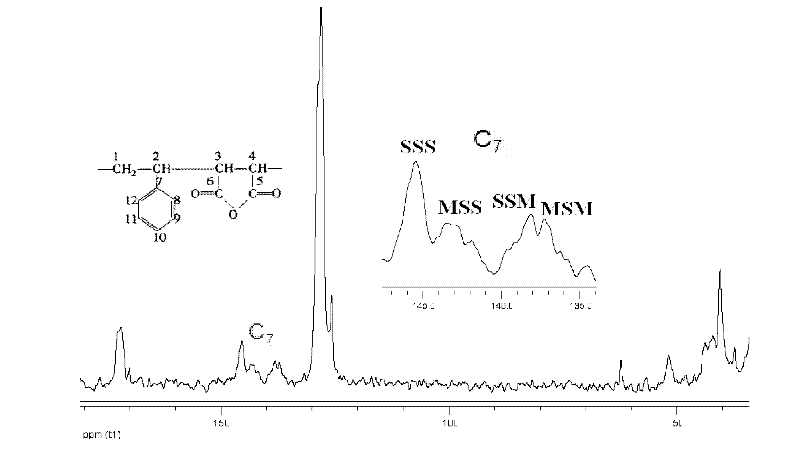

[0032] St and MAn molar ratio 8: 2, wherein MAn 1.37g, St 5.80g; initiator is dicumyl peroxide (DCP) 0.357g; medium is ethyl butyrate, 30mL (monomer mass concentration 20%) . Heated in an oil bath and reacted at 120°C for 24 hours under the protection of nitrogen to obtain a dispersion system of random copolymer of styrene and maleic anhydride. The dispersion system was centrifuged and dried to obtain styrene-maleic anhydride White powder of random copolymer. The polymerization yield was 82%, and the content of MAn in the copolymer measured by acid-base titration was 21%. The number average molecular weight of the copolymer was 14000 g / mol, and the molecular weight distribution coefficient was 1.7. The carbon NMR spectrum of the prepared copolymer ( 13 C-NMR) spectrum see figure 1 , illustrating that the copolymer of styrene and maleic anhydride prepared using the present invention is a random copolymer.

Embodiment 3

[0034] St and MAn molar ratio 9.7: 0.3, wherein MAn 0.21g, St 7.03g; Initiator is dicumyl peroxide (DCP) 0.179g; Medium is ethyl butyrate, 30mL (monomer mass concentration 20% ). Heated in an oil bath and reacted at 110°C for 24 hours under the protection of nitrogen to obtain a dispersion system of random copolymer of styrene and maleic anhydride. The dispersion system was separated by filtration and dried to obtain styrene-maleic anhydride White powder of random copolymer. The polymerization yield was 50%, and the content of MAn in the copolymer measured by acid-base titration was 5%. The prepared copolymer of styrene and maleic anhydride is a random copolymer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Number average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com