Sulfonic self-doped aniline copolymer with controllable nanometer structure and synthesis method thereof

A technology of aniline copolymer and nanostructure, which is applied in the preparation of sulfonic acid, organic chemistry, etc., can solve the problems of poor processing performance and achieve the effect of simple synthesis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

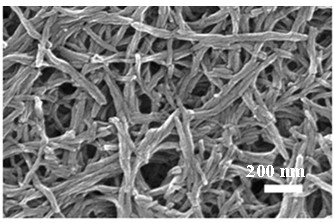

[0107] Synthesis of pure aniline nanofibers as an aniline / aniline-2-sulfonic acid (100 / 0) copolymer

[0108] The molar ratio of aniline / aniline-2-sulfonic acid copolymerization is 100 / 0, that is, accurately weigh 470 mg (5 mmol) aniline and dissolve in 25 mL 1.0 mol / L hydrochloric acid to form a comonomer solution;

[0109] According to the initiator N - The molar ratio of phenylphenylenediamine and aniline monomer is 1:50, weigh 23.5 mg (0.1 mmol) N - phenylphenylenediamine was dissolved in 1.0 mL methanol to form an initiator solution;

[0110] According to the molar ratio of oxidant and aniline monomer of 1 / 1, 1152.5 mg (5 mmol) of oxidant ammonium persulfate was weighed and dissolved in 25 mL of 1.0 mol / L hydrochloric acid aqueous solution to form an oxidant solution.

[0111] After mixing the initiator solution and the aniline monomer solution evenly, the oxidant solution was added immediately, shaken vigorously for 15 seconds, and then left to react for 24 h. After th...

Embodiment 2

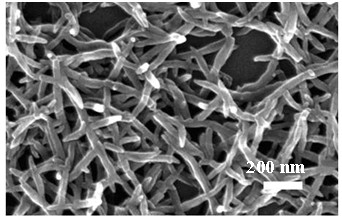

[0114] Synthesis of Aniline / Aniline-2-sulfonic acid (70 / 30) Copolymer

[0115] The molar ratio of aniline / aniline-2-sulfonic acid copolymerization is 70 / 30, that is, accurately weigh 329 mg (3.5 mmol) of aniline and 273 mg (1.5 mmol) of aniline-2-sulfonic acid in 25 mL of 1.0 mol / L hydrochloric acid , forming a comonomer solution;

[0116] According to the initiator N - Phenylphenylenediamine and comonomer molar ratio is 1 / 50 and weighed 23.5 mg (0.1 mmol) N - phenylphenylenediamine was dissolved in 1.0 mL methanol to form an initiator solution;

[0117] According to the molar ratio of oxidant and comonomer as 1 / 1, 1152.5 mg (5 mmol) of ammonium persulfate was weighed and dissolved in 25 mL of 1.0 mol / L hydrochloric acid aqueous solution to form an oxidant solution.

[0118] After mixing the initiator solution and the comonomer solution evenly, the oxidant solution was added immediately, shaken vigorously for 15 seconds, and then left to react for 24 h. After the reaction ...

Embodiment 3

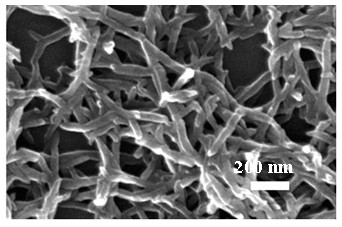

[0120] Synthesis of Aniline / Aniline-2-sulfonic acid (50 / 50) Copolymer

[0121] The molar ratio of aniline / aniline-2-sulfonic acid copolymerization was 50 / 50, and Example 2 was repeated to finally obtain black aniline / aniline-2-sulfonic acid (50 / 50) copolymer powder particles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com