Halogen-free flame-retardant epoxy resin composition and prepreg and printed circuit board made therefrom

A halogen epoxy resin and epoxy resin technology, which is applied in the field of epoxy resin compositions, can solve the problems of reducing the solder dip resistance of substrates, poor electrical characteristic dissipation factor and dielectric constant, and reducing the adhesion of copper foil to substrates, etc. Achieve good dip solder resistance and avoid brittleness problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

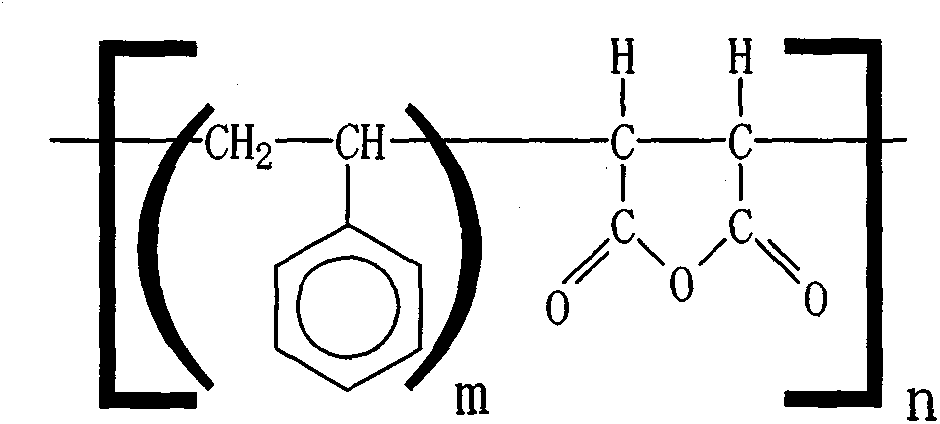

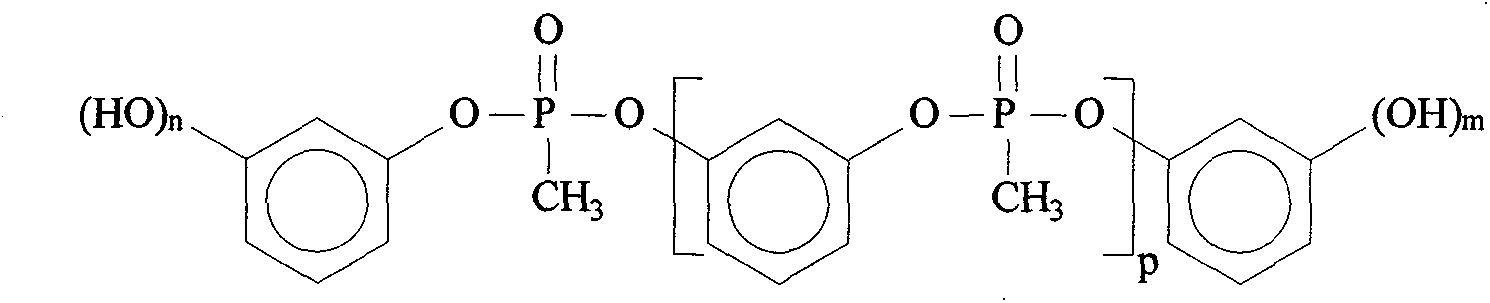

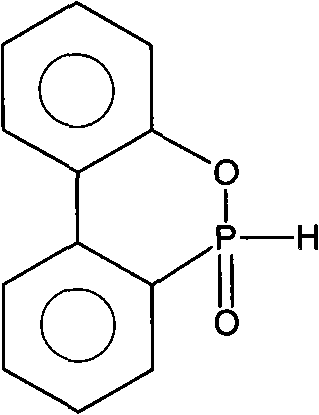

[0031] 100 parts by weight of phosphorus-containing (DOPO) o-cresol novolac epoxy resin, 15 parts by weight of styrene-maleic anhydride copolymer, 40 parts by weight of polymethyl phosphate 1,3-phenylene ester, 0.5 parts by weight Parts of 2-methylimidazole and 15 parts by weight of silicon dioxide were mixed using a stirrer at room temperature for 60 minutes, and then 30 parts by weight of methyl ethyl ketone was added. After the above materials were stirred at room temperature for 120 minutes, a halogen-free flame-retardant epoxy resin composition varnish was formed.

Embodiment 2

[0033] 100 parts by weight of phosphorus-containing (DOPO) o-cresol novolac epoxy resin, 15 parts by weight of styrene-maleic anhydride copolymer, 30 parts by weight of polymethyl phosphate 1,3-phenylene ester, 0.5 parts by weight Parts of 2-methylimidazole and 15 parts by weight of silicon dioxide were mixed using a stirrer at room temperature for 60 minutes, and then 30 parts by weight of methyl ethyl ketone was added. After the above materials were stirred at room temperature for 120 minutes, a halogen-free flame-retardant epoxy resin composition varnish was formed.

Embodiment 3

[0035] 100 parts by weight of phosphorus-containing (DOPO) o-cresol novolac epoxy resin, 15 parts by weight of styrene-maleic anhydride copolymer, 60 parts by weight of polymethyl phosphate 1,3-phenylene ester, 0.5 parts by weight Parts of 2-methylimidazole and 15 parts by weight of silicon dioxide were mixed using a stirrer at room temperature for 60 minutes, and then 30 parts by weight of methyl ethyl ketone was added. After the above materials were stirred at room temperature for 120 minutes, a halogen-free flame-retardant epoxy resin composition varnish was formed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com