Method for producing guanosine by fermentation with bacillus

A technology of bacillus and guanosine, applied in the field of guanosine production, can solve problems such as no patent reports, and achieve the effects of releasing metabolic regulation, improving transformation rate, and being easy to popularize.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

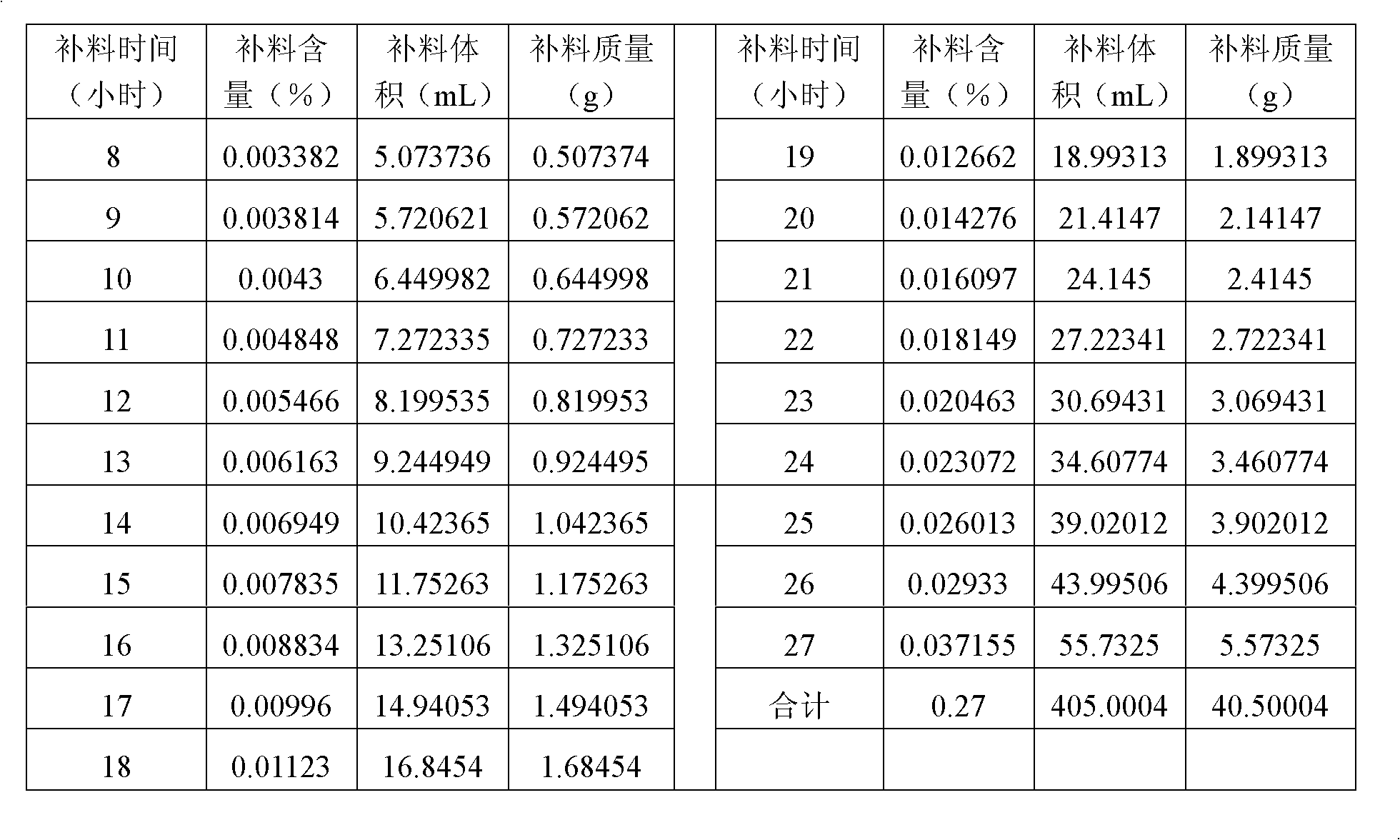

Examples

Embodiment 1

[0037] (1) Cell activation

[0038] Streak inoculation of Bacillus subtilis CGMCC No.4587 on the slant of nutrient broth agar test tube, then transfer to the slant of agar eggplant bottle to cultivate and mature, ready for transplantation; culture medium and agar eggplant for nutrient broth agar test tube slant culture The culture medium for bottle slant culture is: glucose 5g / L, peptone 10g / L, yeast extract 10g / L, NaCl 5g / L, agar 20g / L, pH 7.0-7.2, culture temperature uniform 32℃, culture time uniform for 24-48 hours.

[0039] (2) Seed cultivation

[0040] Bacillus subtilis JSIM-G518 slant refrigerated strains were streaked and inoculated on the slant of nutrient broth agar test tube. The slant medium consisted of: glucose 5g / L, peptone 10g / L, yeast extract 10g / L, NaCl 5g / L L. Agar 20g / L, pH 7.2, cultured at 32°C for 48 hours, it is mature.

[0041] On the clean bench in the sterile room, pick a ring of activated test tube slant bacteria and inoculate it into the sterilize...

Embodiment 2

[0047] Step (1) is with embodiment 1.

[0048] Step (2) Seed culture

[0049] Bacillus subtilis JSIM-G518 slant refrigerated strains were streaked and inoculated on the slant of nutrient broth agar test tube. The slant medium consisted of: glucose 5g / L, peptone 10g / L, yeast extract 10g / L, NaCl 5g / L L. Agar 20g / L, pH 7.2, cultivated at 32°C for 48 hours. Then transfer to the slant of the agar eggplant bottle (the composition of the medium is the same as that of the test tube slant), culture at 32° C. for 48 hours, and mature.

[0050] Prepare a sterile triangular flask with glass beads inside, scrape and wash the mature fungal slime on the slope of the eggplant bottle with sterile water, put it into the triangular flask, oscillate and disperse the fungal slime to obtain a uniform bacterial suspension; press the bacterial suspension to 10% of the inoculum was inserted into a 100-liter seed tank, and the filling factor of the seed tank was 70% (V / V). The composition of the see...

Embodiment 3

[0060] 1. Collect 70 liters of guanosine fermentation liquid, send it into the storage tank, heat the jacket to about 95°C, and keep it warm for 15 minutes; filter it with a plate and frame filter press while heating, and the filtration pressure is 0.40Mpa. The bacteria are used as feed protein, and the filtrate is sent to the storage tank;

[0061] 2. Add 0.2% volume of natural flocculant ZTC-II (or one of chitosan, chitin, and sodium alginate) to the filtrate (prepared to a solution with a weight concentration of 1%), and keep the jacket at 32°C , flocculation and sedimentation for 12 hours to remove protein, take the supernatant and send it to the storage tank.

[0062] 3. The supernatant was treated with a ceramic membrane, and the membrane filtration temperature was 75°C; the filtrate was concentrated to 1 / 5 volume under reduced pressure and vacuum at 60°C.

[0063] 4. After adjusting the pH of the concentrated solution to 7.0, send it to a crystallization tank, stir, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com