Static suspension six-axis micro accelerometer and manufacturing method thereof

A micro-accelerometer, electrostatic levitation technology, applied in the direction of measuring acceleration, velocity/acceleration/impact measurement, manufacturing microstructure devices, etc., can solve the problems of high manufacturing cost, high processing equipment cost, complex process, etc. Sensitivity, small device damage, and low temperature effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

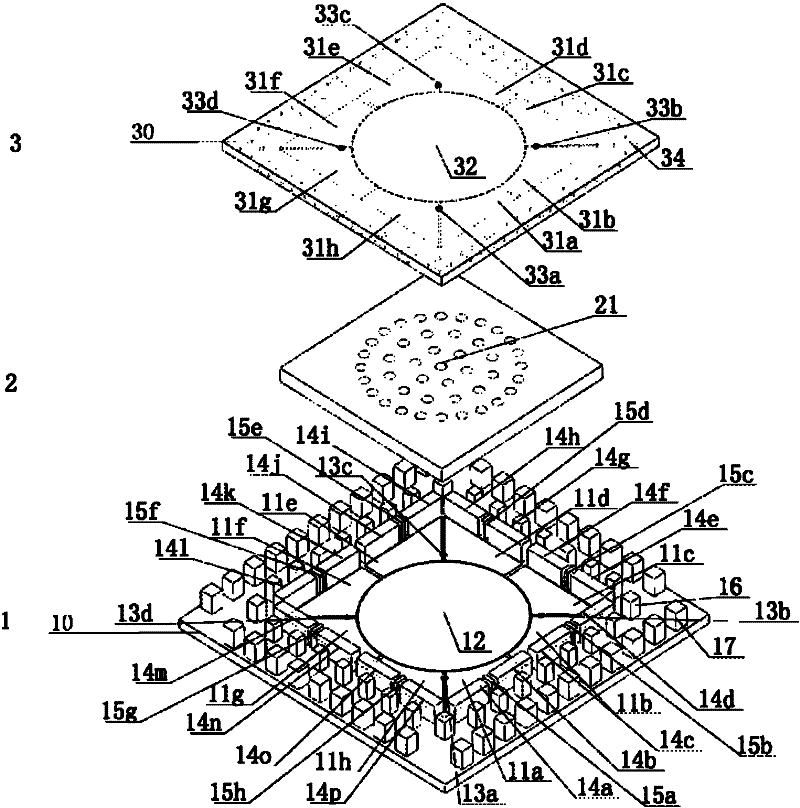

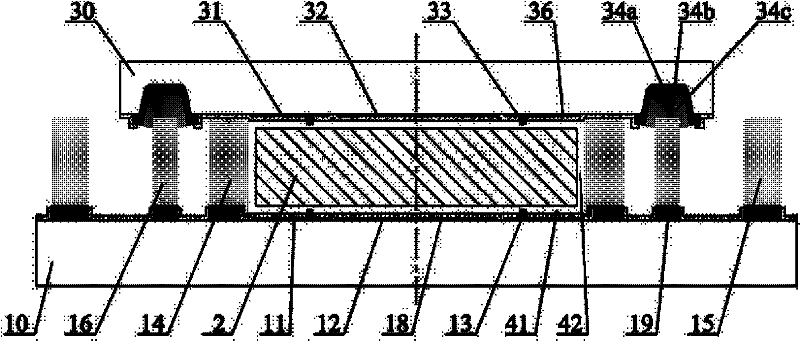

[0059] Such as figure 1 , figure 2 As shown, this embodiment adopts a sandwich-type three-layer bonded structure: a lower stator 1 , a suspended sensitive mass 2 with a square plate structure, and an upper stator 3 .

[0060] Such as figure 1 , figure 2 As shown, thin-film metal axial electrodes 11, axial stoppers 13, thick metal structures 14-17 and lead wires are arranged on the lower stator 1, wherein the thin-film metal electrodes include axial suspension control electrode pairs arranged along the X-axis 11a, 11b and 11e, 11f, the axial suspension control electrode pairs 11e, 11d and 11g, 11h arranged along the Y axis, and the center is a circular common electrode 12; set between the pairs of adjacent axial suspension control electrodes There are four axial stop posts 13 above the plane of the membrane electrode. The thick metal structure includes lateral electrodes 14, lateral stoppers 17, pins 15 and upper pole plate lead posts 16, wherein: the upper pole plate lea...

Embodiment 2

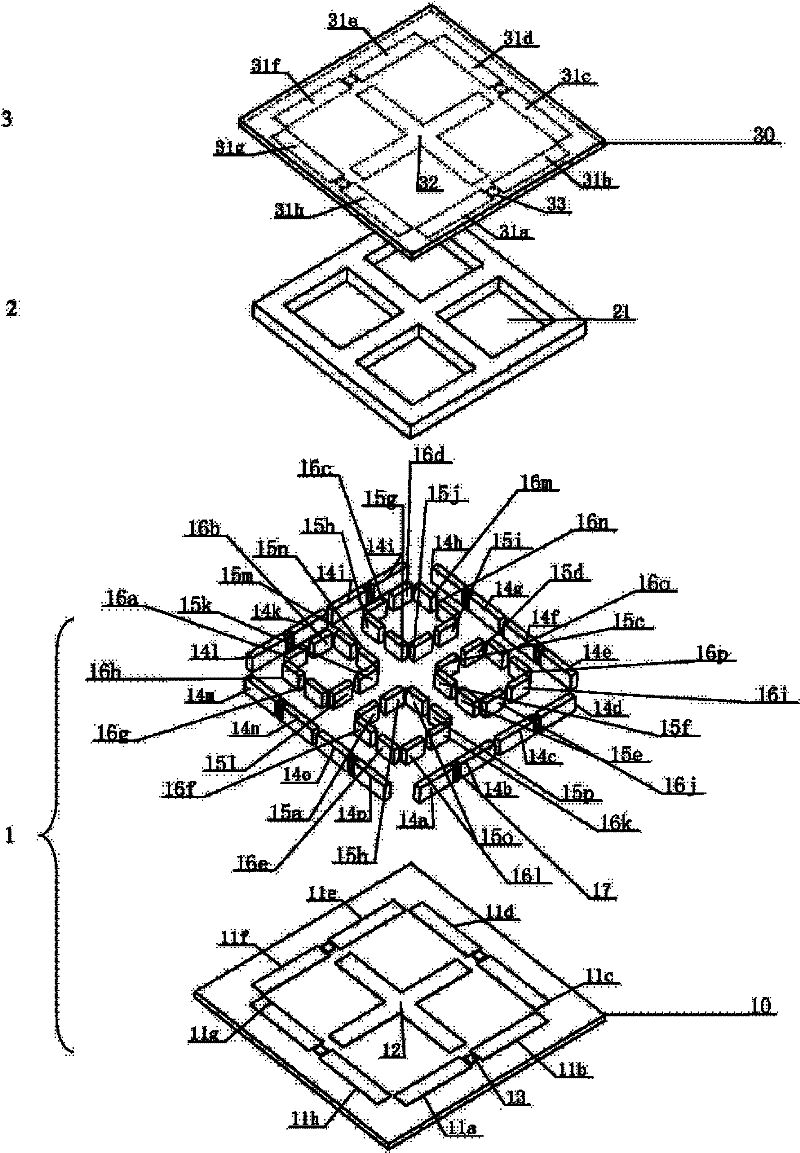

[0063] Such as image 3 Shown is another embodiment of the electrostatic levitation six-axis micro accelerometer of this embodiment. It also adopts a sandwich-type three-layer bonding structure, which is composed of a lower stator 1, a square sensitive mass 2 and an upper stator 3 respectively. In this embodiment, the square sensitive mass 2 is a square-shaped structure with square hollow holes 21 at its four corners. Same as the first embodiment, the stator structure also includes thin-film metal electrodes, stoppers, thick metal structures and leads; corresponding to the square-shaped mass block, the different structures are mainly thin-film electrodes and lateral electrodes. That is, the inner lateral electrodes are mainly arranged in the four square holes of the square-shaped mass block to improve the lateral displacement detection sensitivity of the suspended mass block. image 3 Only the structure of electrodes and stoppers are drawn in the figure.

[0064] Such as ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com