Heat-curable ink composition

A thermosetting, composition technology, used in the field of electronics, which can solve the problem of expensive special fillers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

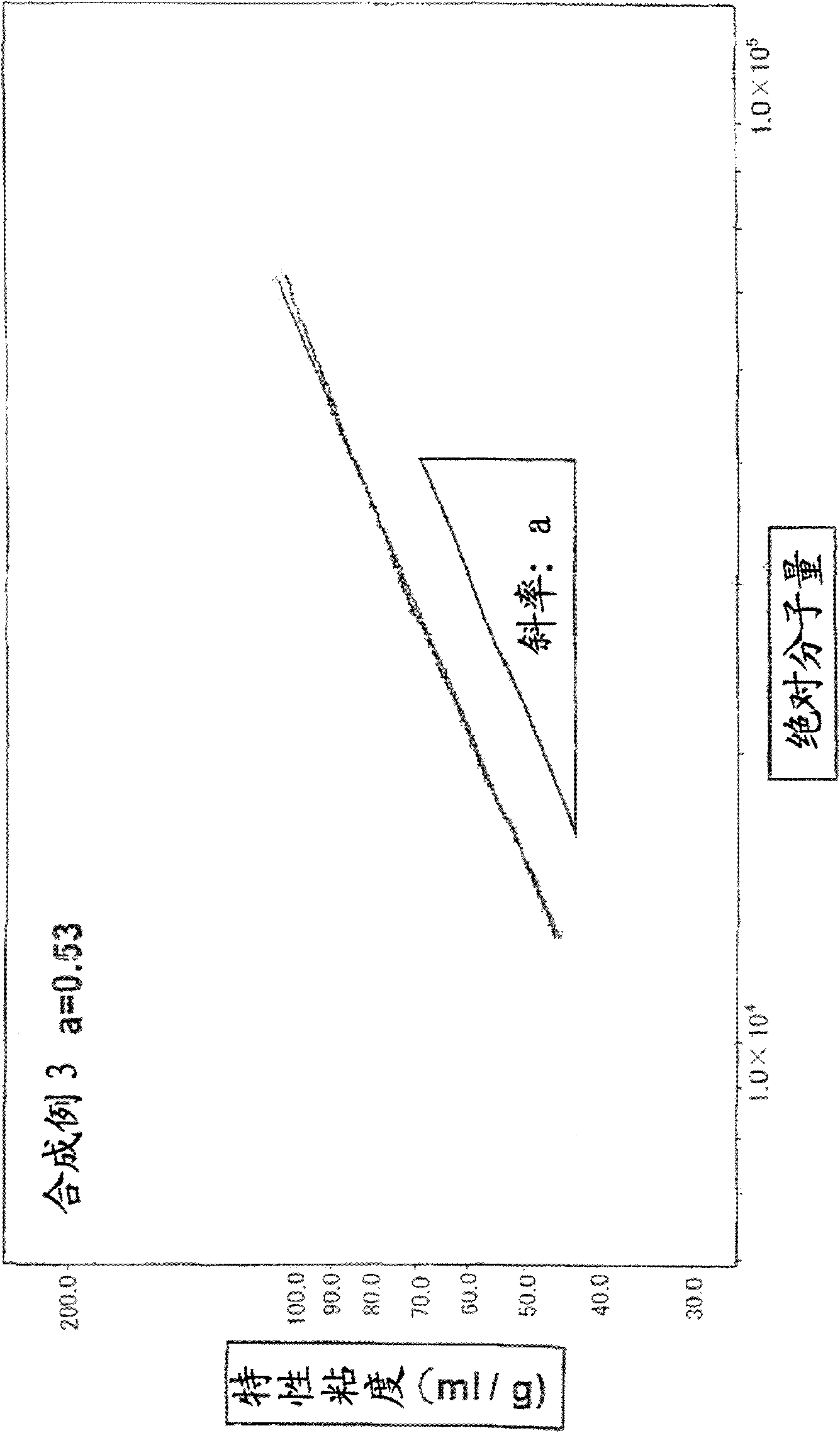

[0073] Hereinafter, the present invention will be more specifically described based on examples, but the present invention is not limited to these examples.

[0074]

[0075] The configuration and conditions of the GPC apparatus are as follows.

[0076] Pump: Alliance (registered trademark) 2695 manufactured by Waters,

[0077] Differential refractometer: Waters 2410,

[0078] Multi-angle light scattering detector: DAWN (registered trademark) HELEOS8+ (registered trademark) manufactured by Wyatt Corporation,

[0079] Intrinsic viscosity detector: ViscoStar (registered trademark) manufactured by Wyatt Corporation,

[0080] Column: Three Shodex (registered trademark) columns GPC KF805L, GPCKF803L, and GPCKF802.5L manufactured by Showa Denko Co., Ltd. were connected and used.

[0081] Solvent: THF

[0082] The absolute molecular weight and intrinsic viscosity were measured under the conditions of a sample concentration of 0.01 mg / ml, a flow rate of 1.0 ml / min, and a measure...

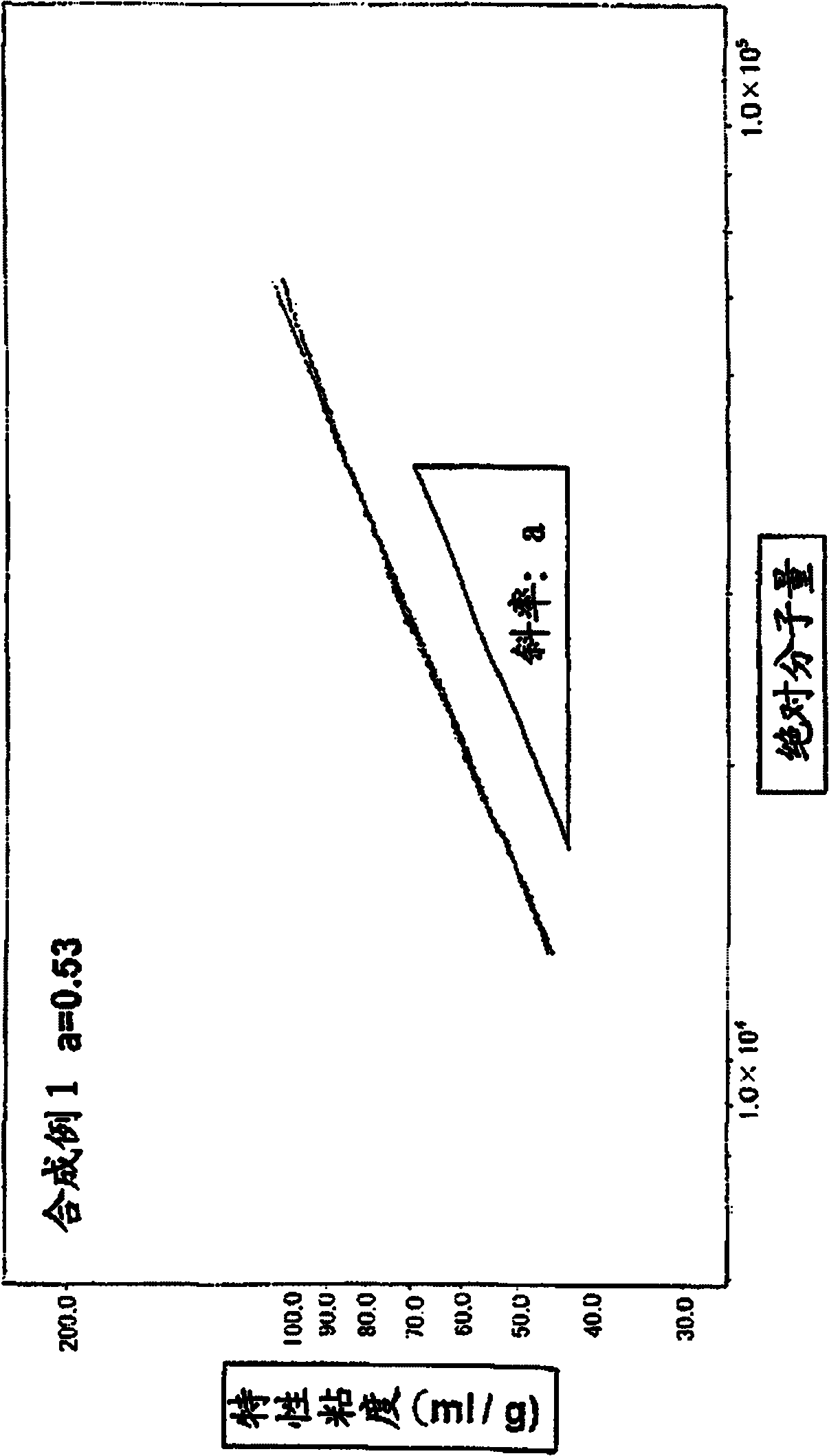

Synthetic example 1

[0089] "C-1015N" (polycarbonate diol, raw material diol molar ratio: 1,9-nonanediol: 2-methyl-1,8-octanediol=15:85, molecular weight 991) 219.8 g, 2,2-dimethylolbutyric acid (manufactured by Nippon Chemicals Co., Ltd.) which is a carboxyl group-containing dihydroxy compound 42.2 g, 2.4 g of trimethylolethane (manufactured by Mitsubishi Gas Chemical Co., Ltd.) as a trifunctional or higher polyhydric alcohol, 600.0 g of diethylene glycol monoethyl ether acetate (manufactured by Daicel Chemical Co., Ltd.) as a solvent, Heat to 100°C to dissolve all raw materials.

[0090] The temperature of the reaction solution was lowered to 90° C., and methylene bis(4-cyclohexyl isocyanate) (manufactured by Sumika Bayeluretan Co., Ltd. Trademark)) 134.3 g. It was made to react at 120 degreeC for 6 hours, and after confirming that almost all isocyanates disappeared, 2.1 g of isobutanol (made by Wako Pure Chemical Industries, Ltd.) was dripped, and it was made to react at 90 degreeC for 3 hour...

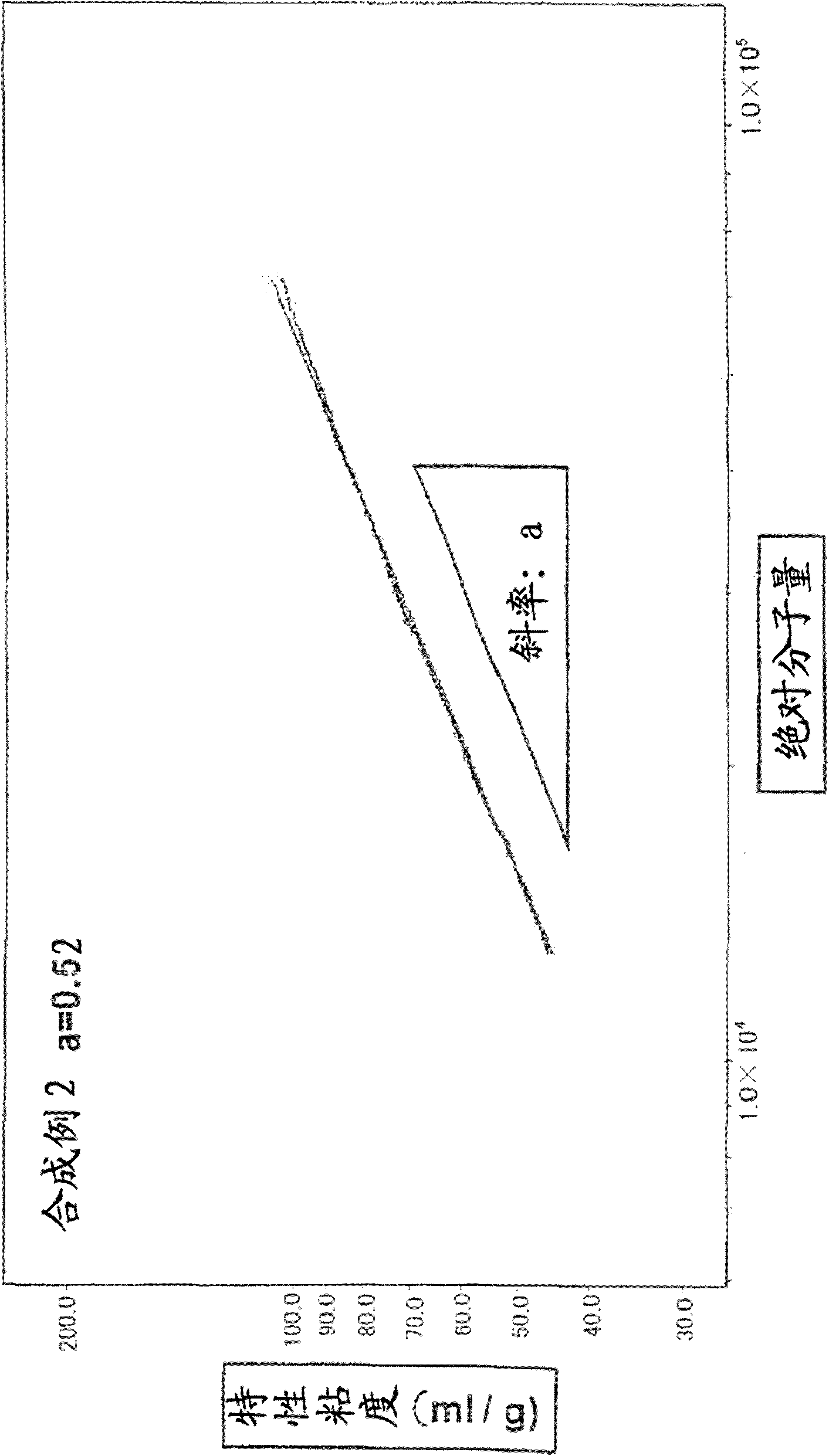

Synthetic example 2

[0095] Into a reaction vessel equipped with a stirring device, a thermometer, and a condenser, UH-CARB80 (registered trademark, a polycarbonate diol derived from 1,6-hexanediol) was added as a polyol compound manufactured by Ube Industries, Ltd. : Number average molecular weight (800) 177.4 g, 2,2-dimethylolpropionic acid (manufactured by Nippon Chemical Industry Co., Ltd.) 38.2 g as a carboxyl group-containing dihydroxy compound, trimethylol as a trifunctional or higher polyol 2.7 g of propane (manufactured by Mitsubishi Gas Chemical Co., Ltd.) and 600.0 g of diethylene glycol monoethyl ether acetate (manufactured by Daicel Chemical Co., Ltd.) as a solvent were heated to 100° C. to dissolve all the raw materials.

[0096] The temperature of the reaction solution was lowered to 90° C., and isophorone diisocyanate ("DesModule-I" (registered trademark) manufactured by Sumika Bayeruretan Co., Ltd.) 113.6 g. It was made to react at 120 degreeC for 6 hours, and after confirming th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com