A simple method for preparing titanium dioxide multi-shell hollow spheres and sphere-in-sphere structures

A technology of titanium dioxide and hollow spheres, which is applied in the direction of titanium dioxide, titanium oxide/hydroxide, nanostructure manufacturing, etc., to achieve the effect of simple and easy method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

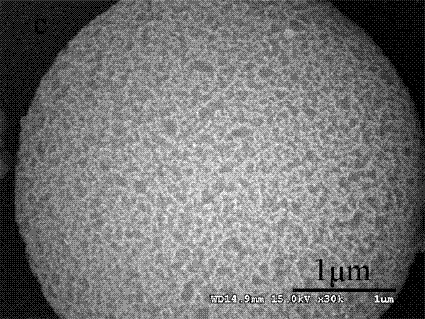

[0029] Preparation of multi-shell hollow spheres

[0030] 1) Prepare porous polymer spheres as templates:

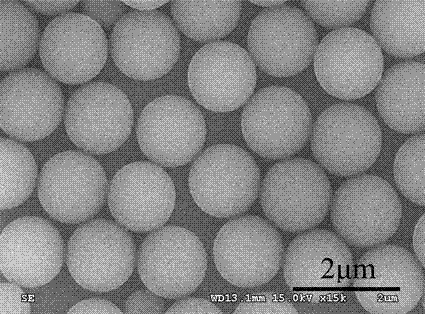

[0031] ① Prepare polystyrene microspheres as seed bulbs. Dissolve polyvinylpyrrolidone (2.0g) in a mixed solvent of ethanol (60.4g) and water (7.6g), then add styrene (30g) and azobisisobutylacetonitrile (0.3g), protect with nitrogen for 30min, and stir at 100rpm 30min, then be warming up to 70 DEG C, react 12h. After the reaction, it was centrifuged and washed several times with water and ethanol. structured as figure 1 shown.

[0032] ② Disperse the bulbs in 0.4% sodium lauryl sulfate aqueous solution (0.27g / ml). Then azobisisobutylcyanide (0.026g) was dissolved in polystyrene (4.4ml), added to aqueous sodium lauryl sulfate solution (30ml, 0.4%), and emulsified in an ultrasonic bath. Add the above-mentioned emulsion dropwise to the bulb dispersion, keep it warm at 35°C for 12 hours, remove the upper layer of oil layer that has not been absorbed by the bulbs with ...

Embodiment 2

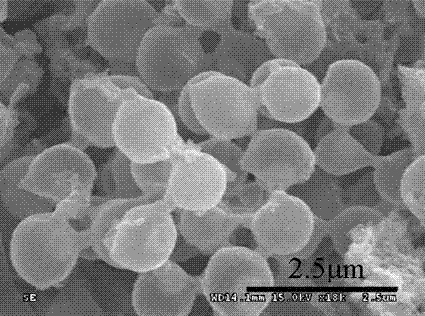

[0039] Preparation of sphere-in-sphere structures

[0040] 1) Prepare porous polymer spheres as templates:

[0041] ① Prepare polystyrene microspheres as seed bulbs. Dissolve polyvinylpyrrolidone (2.0g) in a mixed solvent of ethanol (60.4g) and water (7.6g), then add styrene (30g) and azobisisobutylacetonitrile (0.3g), protect with nitrogen for 30min, and stir at 100rpm 30min, then be warming up to 70 DEG C, react 12h. After the reaction, it was centrifuged and washed several times with water and ethanol.

[0042] ② Disperse the bulbs in 0.4% sodium lauryl sulfate aqueous solution (0.27g / ml). Then azobisisobutylcyanide (0.026g) was dissolved in polystyrene (4.4ml), added to aqueous sodium lauryl sulfate solution (30ml, 0.4%), and emulsified in an ultrasonic bath. Add the above-mentioned emulsion dropwise to the bulb dispersion, keep it warm at 35°C for 12 hours, remove the upper layer of oil layer that has not been absorbed by the bulbs with a separatory funnel, and then a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com