Pretreatment and Recovery Method of Ammonia Nitrogen in Acrylic Fiber Wastewater

A recovery method, ammonia nitrogen recovery technology, applied in textile industry wastewater treatment, water/sewage treatment, water/sludge/sewage treatment, etc., can solve problems such as unsatisfactory biochemical effects, impact of biochemical treatment, system collapse, etc., and achieve good results Socio-economic benefits, reduced processing costs, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0029] The test took the high ammonia nitrogen wastewater produced in the dimethylacetamide (DMCA) production section of the wet acrylic fiber production process of a chemical fiber factory in Jilin as the research object. The ammonia nitrogen content was 975.36-1030.07mg / L, the phosphorus content was not detected, and the COD was 208.51 ~216.43mg / L.

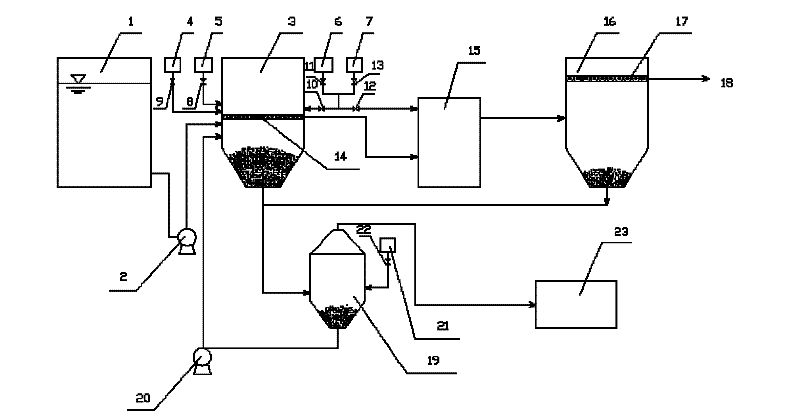

[0030] Such as figure 1 As shown, it is a schematic flow diagram of the system, including struvite crystallization steps, struvite pyrolysis regeneration and ammonia nitrogen recovery steps, recycling steps after regeneration, etc.

[0031] Struvite crystal formation steps:

[0032] First analyze the ammonia nitrogen concentration of the waste water in the waste water storage tank 1, calculate the magnesium source and the phosphorus source amount that need to set up, then pass through the acid solution (10%H 2 SO 4 ) pool 6 and lye pool (10% NaOH) 7 to adjust the pH value of wastewater to 10.25-10.75.

[0033] After adjustin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com