Novel hollow sodium filled valve

A hollow valve technology, which is applied in the field of gas vehicle parts, can solve the problems of high working temperature, valves that cannot meet the requirements of internal combustion engines, and poor heat dissipation performance of valves, so as to ensure heat dissipation performance, reduce weight, ensure corrosion resistance and use The effect of longevity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the drawings.

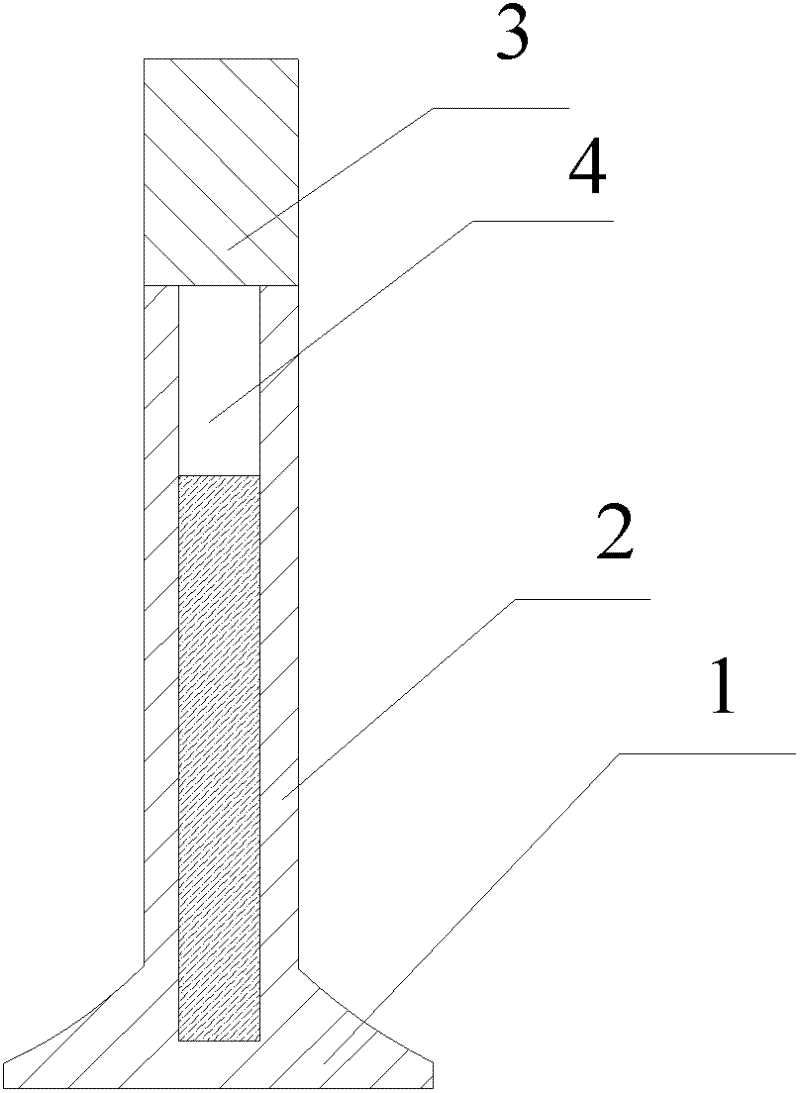

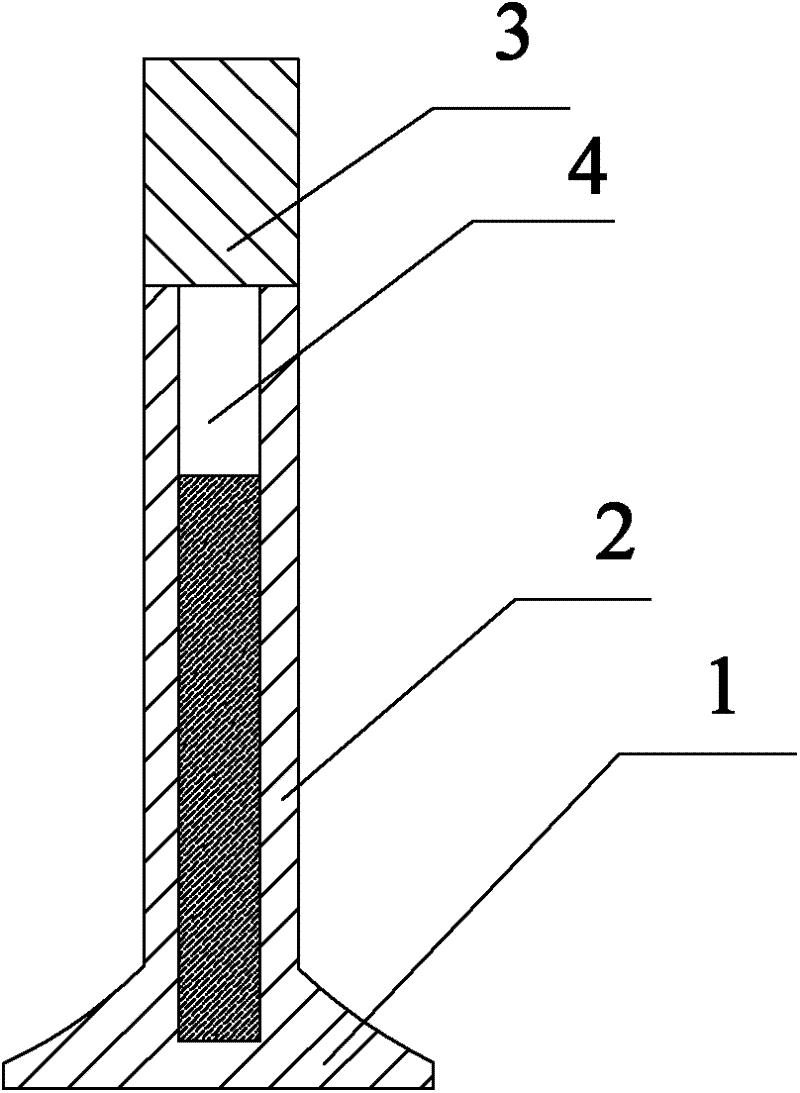

[0014] As shown in the figure, in order to solve the above technical problems, a new type of hollow sodium valve of the present invention is composed of a disc 1, a shaft 2 and a plug 3. The shaft 2 has a hollow part 4 along the axial direction. The hollow part 4 is filled with metallic sodium material, and the quantity of metallic sodium material is not limited. In this embodiment, in order to improve the heat dissipation of the valve, metallic sodium occupies 50%-60% of the volume of the hollow part 4, because metallic sodium It occupies 50%-60% of the volume of the hollow part. When the metallic sodium is converted from solid to liquid, it can make the liquid metallic sodium easier to flow up and down, ensuring the fluidity and thermal conductivity of the liquid metallic sodium, thereby further improving the cost Invention of heat dissipation.

[0015] During processing, the metal s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com