A kind of high temperature proton transport composite membrane for fuel cell and preparation method

A fuel cell and composite membrane technology, which is applied to fuel cell parts, fuel cells, battery pack parts, etc., can solve problems such as electrical conductivity decline, improve sealing performance, improve overall performance, and enhance toughness and plasticity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The invention relates to a high-temperature proton transport composite membrane and a preparation method thereof. The membrane has good proton conductivity, high mechanical strength and stability, good alcohol resistance and processability in the temperature range of 150-350°C sex.

[0030] The present invention adopts following technical scheme:

[0031] Combining ammonium phosphate (base complex) with high proton conductivity and high thermal stability with sulfonated polyaryletherketone (sulfone) polymers with good mechanical strength, high thermal stability and alcohol resistance, combining the two Advantages to realize the preparation of new organic-inorganic high-temperature proton transport composite membranes.

[0032] The preparation of the high-temperature proton transport composite membrane can adopt the casting method: the ammonium polyphosphate (base complex) micro / nanoparticles are added to the sulfonated polyaryletherketone (sulfone) polymer solution, an...

Embodiment 1

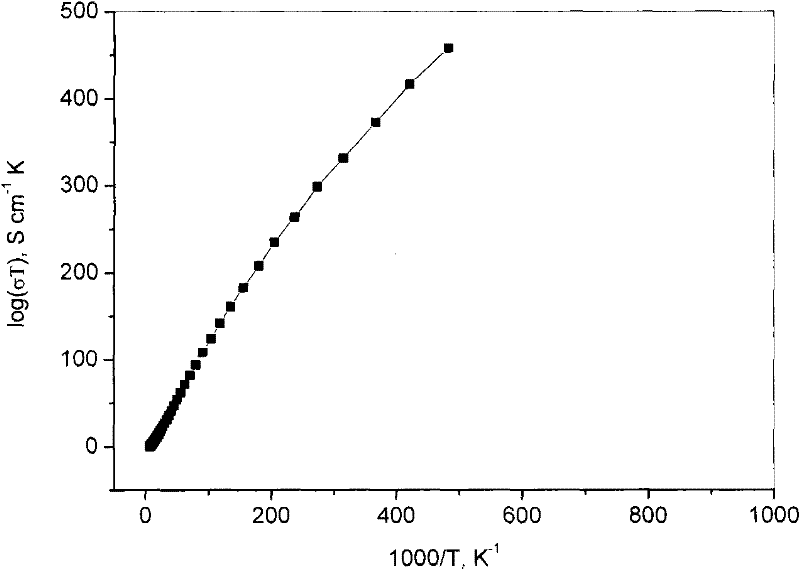

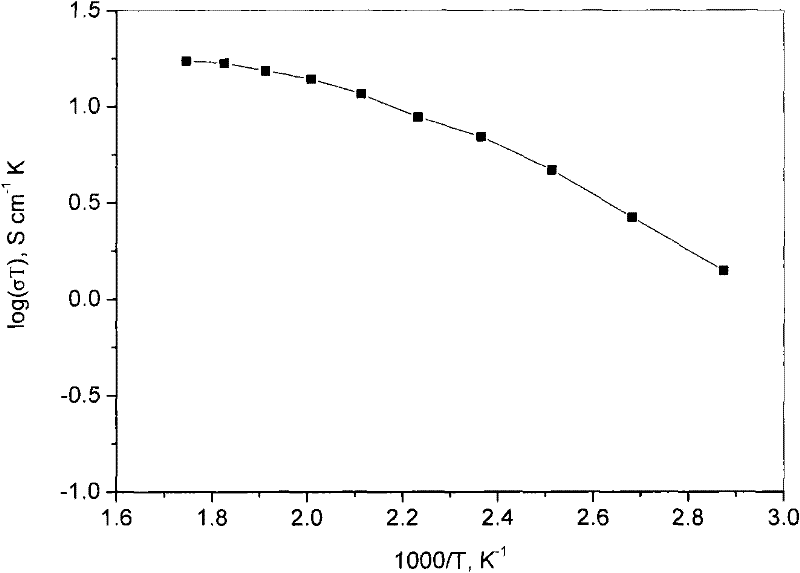

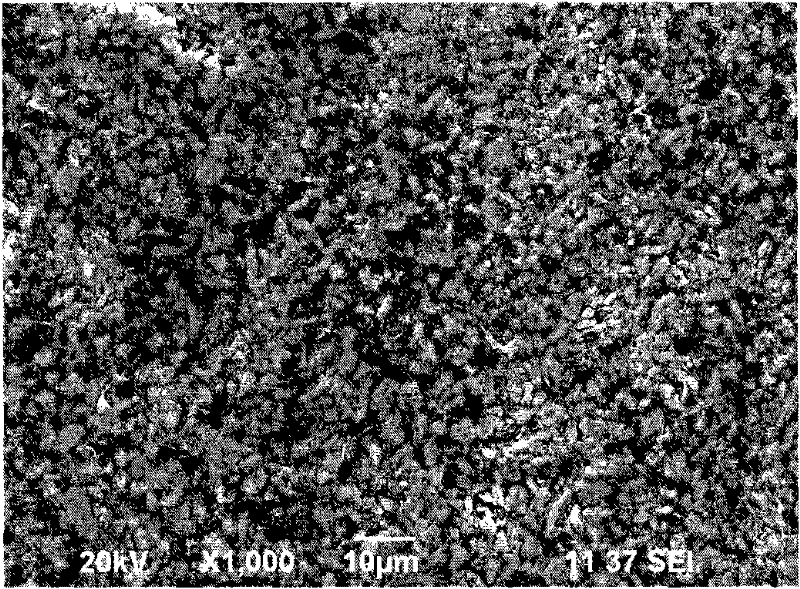

[0038] 5g of sulfonated polyaryletherketone was dissolved in N-methylpyrrolidone to prepare a polymer solution with a volume concentration of 30%, and then 15g of (NH 4 ) 2 Si 0.5 Ti 0.5 P 4 o 13 Added to the polymer solution to form a suspension. Heating to 120°C and stirring for 5 hours (h), ultrasonication for 3 hours, and then using a casting method to obtain an organic-inorganic composite proton membrane, the obtained membrane was completely dried in an oven, and the thickness of the obtained membrane was 0.24mm. The impedance spectrum of the composite film is shown in figure 1 , the Arrhenius curve of conductivity as a function of temperature in humid hydrogen is shown in figure 2 .

Embodiment 2

[0040] 4.5g (NH 4 ) 2 Si 0.7 Ti 0.3 P 4 o 13 and 0.5g NH 4 PO 3 Add it to N, N-dimethylacetamide, stir for 40 minutes, and then sonicate for 2 hours to make it evenly mixed. Mix 5g of 20% by mass sulfonated polyarylethersulfone N-methylpyrrolidone solution with it, stir at 100°C at a speed of 250rpm for 6h, and then sonicate for 2h to obtain a uniformly distributed suspension, and then cast The organic-inorganic composite proton membrane was obtained by the method, and the obtained membrane was completely dried in an oven, and the thickness of the obtained membrane was 0.22 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com