500kv and above 500kv power cable outdoor terminal

A power cable, outdoor technology, applied in the direction of cable terminals, etc., can solve the problems of difficult control of stress cone material quality, poor aging resistance, high temperature resistance, difficult to control material quality, etc., to achieve excellent process formability, good fluidity, Stable and reliable product performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

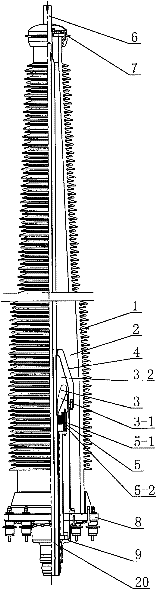

[0022] Such as figure 1 As shown, an outdoor terminal for power cables of 500kV and above includes a bushing 1, an insulating agent 2, a stress cone 3, an epoxy sleeve 4 and a spring compression mechanism 5, and also includes an outlet fitting 6 and an upper cover plate 7 , the lower bottom plate 8 and the tail pipe 9, the stress cone 3 is composed of a conductor 3-1 and an insulator 3-2, and the insulating agent 2 is insulating oil. The stress cone 3 is installed in the casing 1, and the epoxy sleeve 4 is placed on the outside of the stress cone 3. The casing 1 is filled with insulating oil, and the spring compression mechanism 5 connected with the tail pipe 9 is arranged under the stress cone 3. The tightening mechanism 5 includes a spring 5-1 and a spring seat 5-2. The spring 5-1 is arranged between the stress cone 8 and the spring seat 5-2. The stress cone 3 is made of liquid silicone rubber.

Embodiment 2

[0024] Such as figure 1 As shown, it is basically the same as the first embodiment, except that the insulating agent 2 is insulating gas, and the bushing 1 is filled with insulating gas.

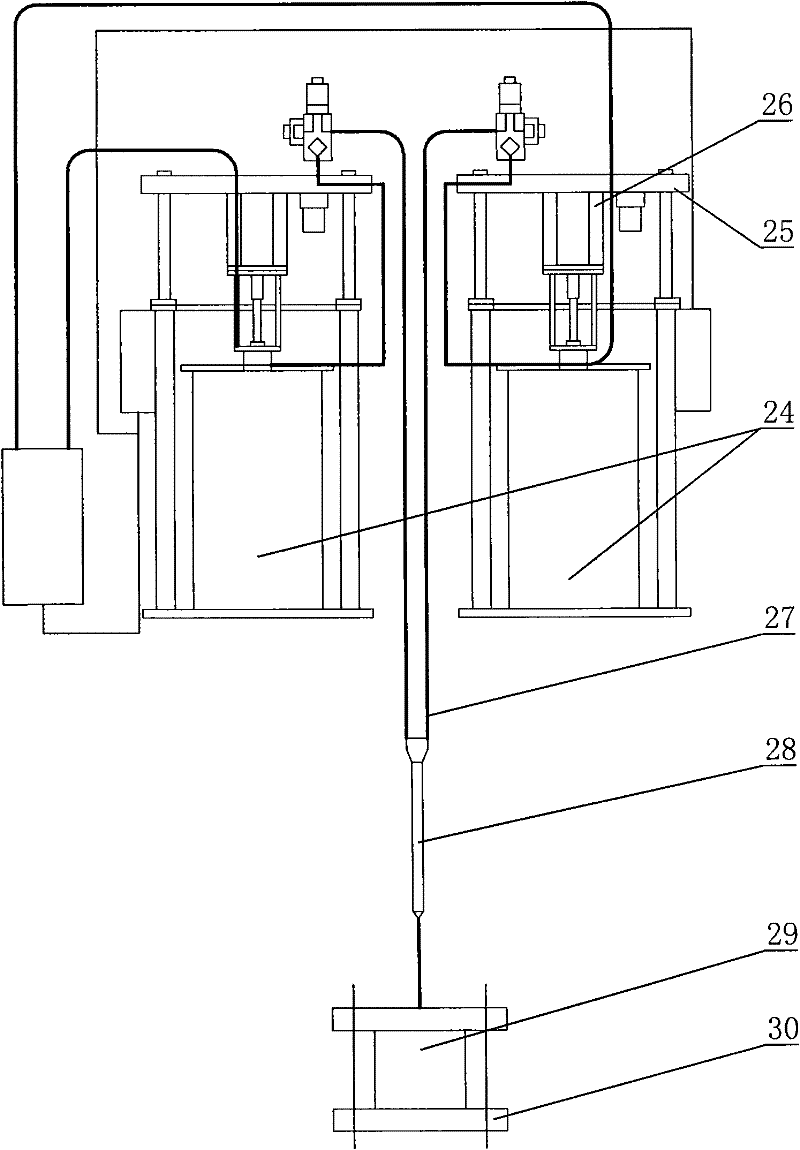

[0025] Such as figure 2 As shown, when the stress cone 3 of the present invention is made, a two-component glue injection machine for liquid silicone rubber is used. The tonnage of the glue injection machine required is 100 tons. The two-component liquid silicone rubber material of component B and component B is placed in the two rubber barrels 24 of the injection machine, and the material is injected into the material tube 27 through the injection pump 26 on the injection frame 25, and the material is mixed. After being mixed with the mold 28, it is injected into the mold cavity in the mold 29, and the mold 29 is locked by a clamping mechanism 30, and finally the mold 29 is heated and vulcanized to form the stress cone 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com