A kind of silk fibroin tubular scaffold and preparation method thereof

A silk fibroin and tubular technology, applied in the field of silk fibroin tubular scaffolds and its preparation, can solve the problems of limited application space and low mechanical properties of silk fibroin scaffold materials, and achieve good tissue compatibility and excellent biocompatibility Effects on sexual and mechanical properties, good cytocompatibility and degradation properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The embodiment of the invention discloses a method for preparing a silk fibroin tubular scaffold, comprising:

[0030] Weaving the boiled silk thread of silkworm into tubular braid;

[0031] degumming, dialysis and purification of silkworm raw silk to obtain silk fibroin solution;

[0032] Put the tubular braid, silk fibroin solution and adhesive into the mold, take out the tubular mold after being frozen at -80°C to -20°C, and obtain an outer layer of silk fibroin film, a core layer of braid and an inner layer in sequence. Silk fibroin tubular scaffold for silk fibroin membrane.

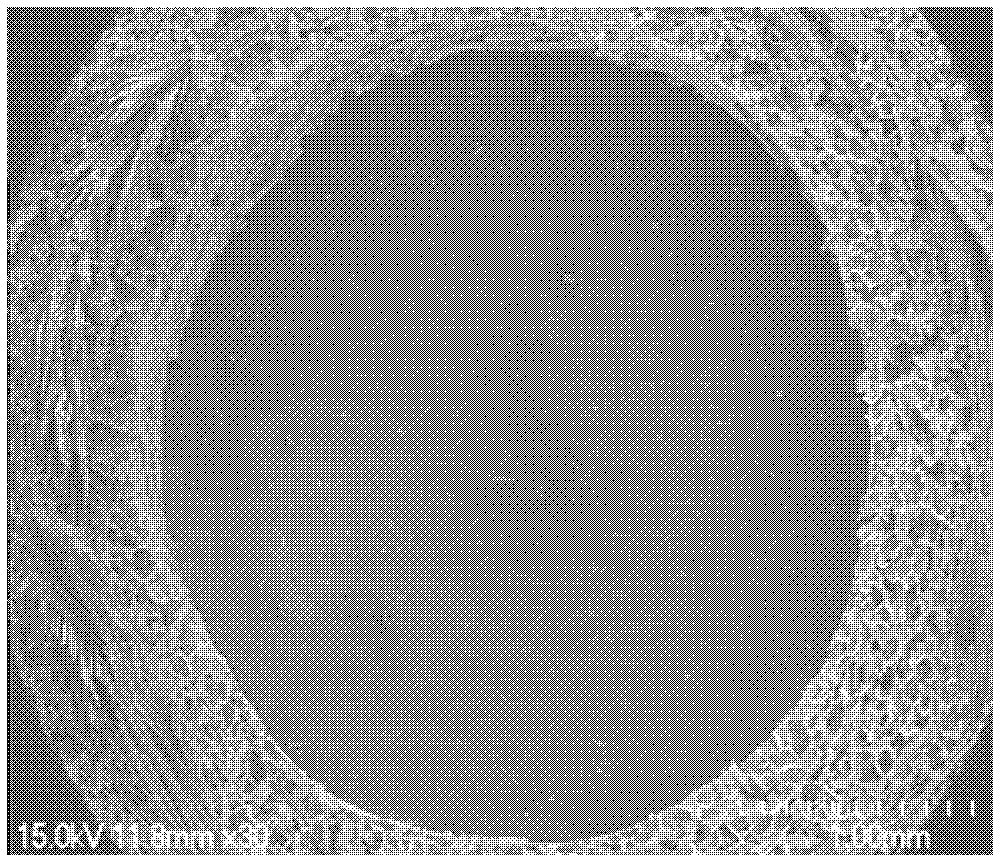

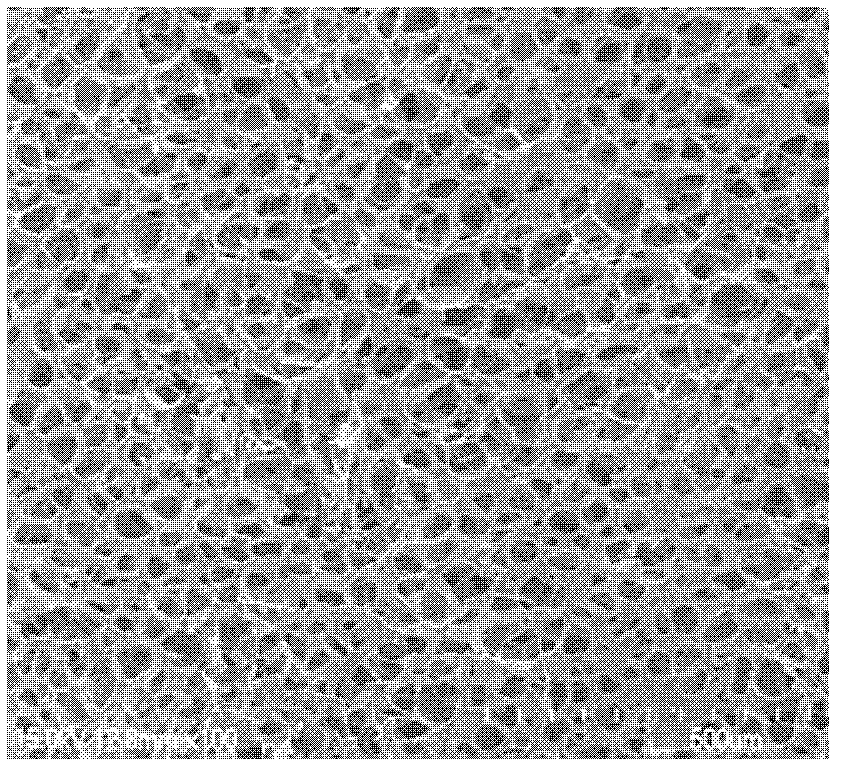

[0033] The silk fibroin tubular stent prepared as above includes sequentially arranged: an outer layer, a core layer and an inner layer, the outer layer and the inner layer are silk fibroin membranes, and the core layer is a braided silkworm silk thread. Among them, the core layer is the skeleton of the entire tubular stent, and the cooked silk thread is a thread formed by twisting several ...

Embodiment 1

[0047] 1. Weave 8×(20 / 22) boiled silk threads into a small-diameter tubular braid with an inner diameter of 3mm.

[0048] 2. Put 0.2 kg silkworm raw silk into 10 liters of sodium carbonate aqueous solution with a concentration of 0.25 g / L, and treat it three times at 98-100° C., and use tap water for the first two times, each time for 30 minutes. For the third time, use deionized water for 45 minutes. Then the silk is fully washed with water, loosened, and dried in an oven at 60° C. to obtain degummed silkworm silk fiber.

[0049] 3. Weigh 10 grams of degummed silkworm silk fibroin and dissolve it in 100 ml of calcium chloride-ethanol aqueous solution with a molar ratio of 1:2, and dissolve at 70° C. for 2 hours to obtain silkworm silk fibroin solution.

[0050] 4. Pour the silkworm fibroin solution into the dialysis bag. The wall of the dialysis bag is a semi-permeable membrane with a molecular weight cut-off of 3.0-20.0kDa. Place the dialysis bag filled with the silkworm si...

Embodiment 2

[0056] 1. Weave 8×(20 / 22) boiled silk threads into a small-diameter tubular braid with an inner diameter of 3mm.

[0057] 2. Put 0.2 kg of silkworm silkworm silk into 10 liters of sodium carbonate aqueous solution with a concentration of 0.25 g / L, and treat it three times at 98-100 ° C. The water in the aqueous sodium carbonate solution used for the first two times is tap water, and each treatment is 30 minutes, and the water in the aqueous sodium carbonate solution used for the third time is deionized water, and the treatment time is 45 minutes. Then the silk is fully cleaned with deionized water, loosened, and dried in an oven at 60° C. to obtain degummed silkworm silk fiber.

[0058] 3. Weigh 10 grams of degummed silkworm silk fibroin and dissolve it in 100 ml of calcium chloride-ethanol aqueous solution with a molar ratio of 1:2, and dissolve at 70° C. for 2 hours to obtain silkworm silk fibroin solution.

[0059] 4. Pour the silkworm fibroin solution into the dialysis ba...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Caliber | aaaaa | aaaaa |

| Tube wall thickness | aaaaa | aaaaa |

| Caliber | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com