Vulcanization method for hydrogenation catalyst and application thereof

A hydrogenation catalyst and catalyst technology, applied in the direction of catalyst activation/preparation, catalyst regeneration/reactivation, chemical instruments and methods, etc., can solve problems such as self-heating of sulfided catalysts, troublesome start-up, etc., and achieve good sulfidation rate , short start-up time and good catalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

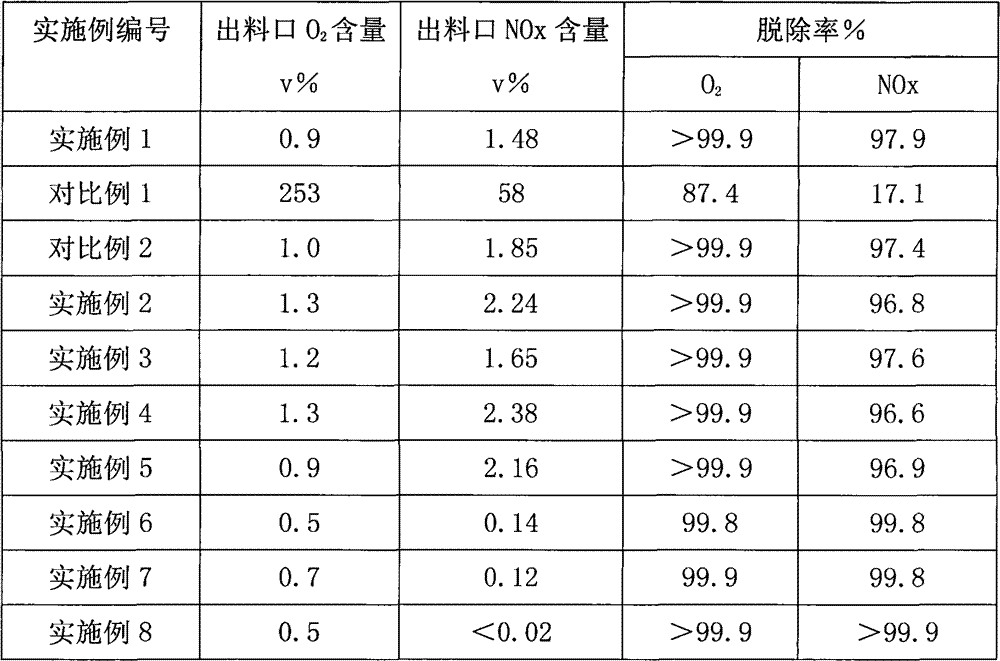

Embodiment 1

[0032] (1) Preparation of phosphorus-containing alumina by sulfuric acid method

[0033] Add 400 ml of deionized water into a container, raise the temperature to 65°C, add an aqueous solution of aluminum sulfate with a specific gravity of 1.14 and an aqueous solution of sodium metaaluminate with a specific gravity of 1.37 under stirring conditions, keep the temperature at 65°C, and adjust the aqueous solution of aluminum sulfate The flow ratio to the sodium metaaluminate aqueous solution is 1:1.0-1.1, so that the pH of the neutralizing solution is 8.5, and the feeding time is 80 minutes. Stop feeding, age for 60 minutes under stirring, filter and wash the filter cake with deionized water 4-6 times, then mix the aluminum hydroxide filter cake and phosphoric acid aqueous solution to make a slurry, after slurrying for 40 minutes, the filter cake is dried at 120°C for 6 hours .

[0034] (2) Preparation of Nitric Acid Process Aluminum Hydroxide

[0035] Add 100 ml of deionized wa...

Embodiment 2

[0055] Except that the catalyst activation temperature is 250°C instead of 230°C, the rest are the same as in Example 1, and the reaction results are shown in Table 2.

Embodiment 3

[0057] Except that the passivation temperature of the catalyst is 30°C instead of 40°C, the rest are the same as in Example 1, and the reaction results are shown in Table 2

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com