Preparation method of composite high-speed steel wear-resistant layer on aluminum alloy surface

A technology of aluminum alloy surface and high-speed steel, applied in metal processing equipment, metal material coating technology, coating, etc., can solve the problems of easy peeling, low bonding strength of wear-resistant coating, and difficulty in meeting the requirements of workpiece use, and achieve The effect of good wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0019] An embodiment of the present invention provides a method for preparing a high-speed steel wear-resistant layer on an aluminum alloy surface, comprising the following steps:

[0020] (a) Aluminum alloy surface degreasing and sandblasting;

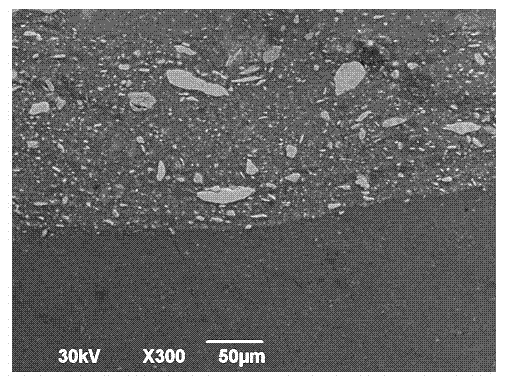

[0021] (b) Thermal spraying high-speed steel coating on the aluminum alloy surface;

[0022] (c) Coating friction stir processing.

[0023] Soak in 3-4% NaCl aqueous solution for 10-20 minutes for degreasing, and then wash with water. Sandblasting uses brown alumina sand grains with a particle size of 500-550μm, the nozzle outlet pressure of the sandblasting machine is 0.6-0.7MPa, and the distance between the nozzle and the product is 25-30mm.

[0024] Thermal spraying is performed on aluminum alloy products that have been degreased and sandblasted on the surface. The raw material for thermal spraying is W18Cr4V or W6Mo5Cr4V2 high-speed steel powder.

[0025] Friction stir processing is performed on aluminum alloy products coated w...

Embodiment 1

[0028] Example 1 Preparation of wear-resistant layer of composite high-speed steel

[0029] Base material: aluminum alloy.

[0030] Coating powder material: High speed steel powder. Powder particle size 20μm-50μm.

[0031] Coating preparation method: Oxygen-acetylene flame spraying. Coating thickness: 0.2mm.

[0032] Friction stir processing process parameters: the diameter of the stirring head is ф10㎜, the rotation speed is 1000rpm, and the moving speed is 20㎜ / min.

Embodiment 2

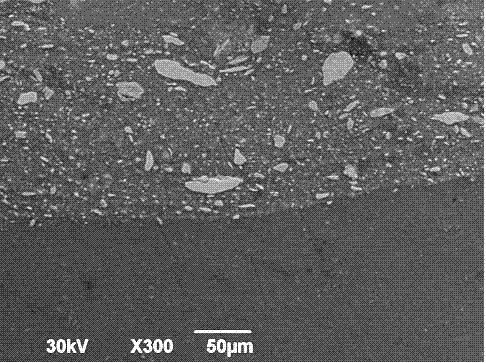

[0033] Example 2 Preparation of wear-resistant layer of composite high-speed steel

[0034] Base material: aluminum alloy.

[0035] Coating powder material: High speed steel powder. Powder particle size 20μm-50μm.

[0036] Coating preparation method: plasma spraying. Coating thickness: 0.5 mm.

[0037] Friction stir processing process parameters: the diameter of the stirring head is ф15㎜, the rotation speed is 1500rpm, and the moving speed is 30㎜ / min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com