Preparation method of lithium ion battery negative electrode material li4ti5o12

A lithium-ion battery and negative electrode material technology, applied in battery electrodes, chemical instruments and methods, circuits, etc., can solve problems such as uneven electrochemical properties of ion battery materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

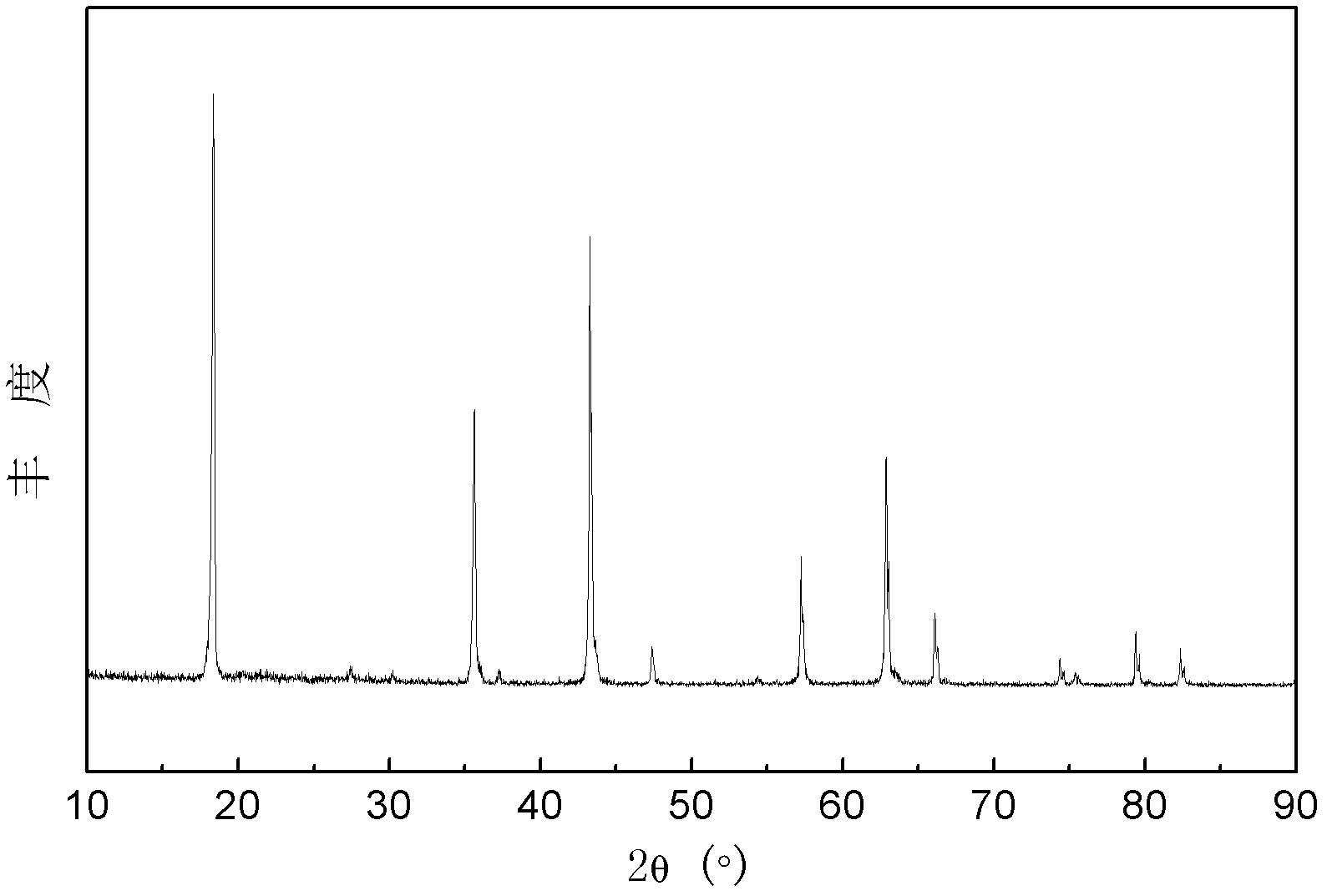

[0009] Specific implementation mode 1: Li-ion battery anode material Li in this implementation mode 4 Ti 5 O 12 The preparation method is as follows: 1. Mix tetrabutyl titanate and absolute ethanol solution according to the volume ratio of 1:5 to form solution A; 2. Dissolve lithium salt in distilled water to form solution B; 3. Mix solution B Pour into solution A while stirring to form a suspension, and the molar ratio of Li element to Ti element in the suspension is 4 to 6:5; 4. Heat the suspension in a water bath at 40°C to 100°C, steam Dry to obtain a precipitate; 5. After the precipitate is ground into powder, transfer it to a tube furnace, and sinter at 600°C-800°C for 2h-16h to obtain Li-ion battery negative electrode material Li 4 Ti 5 O 12 .

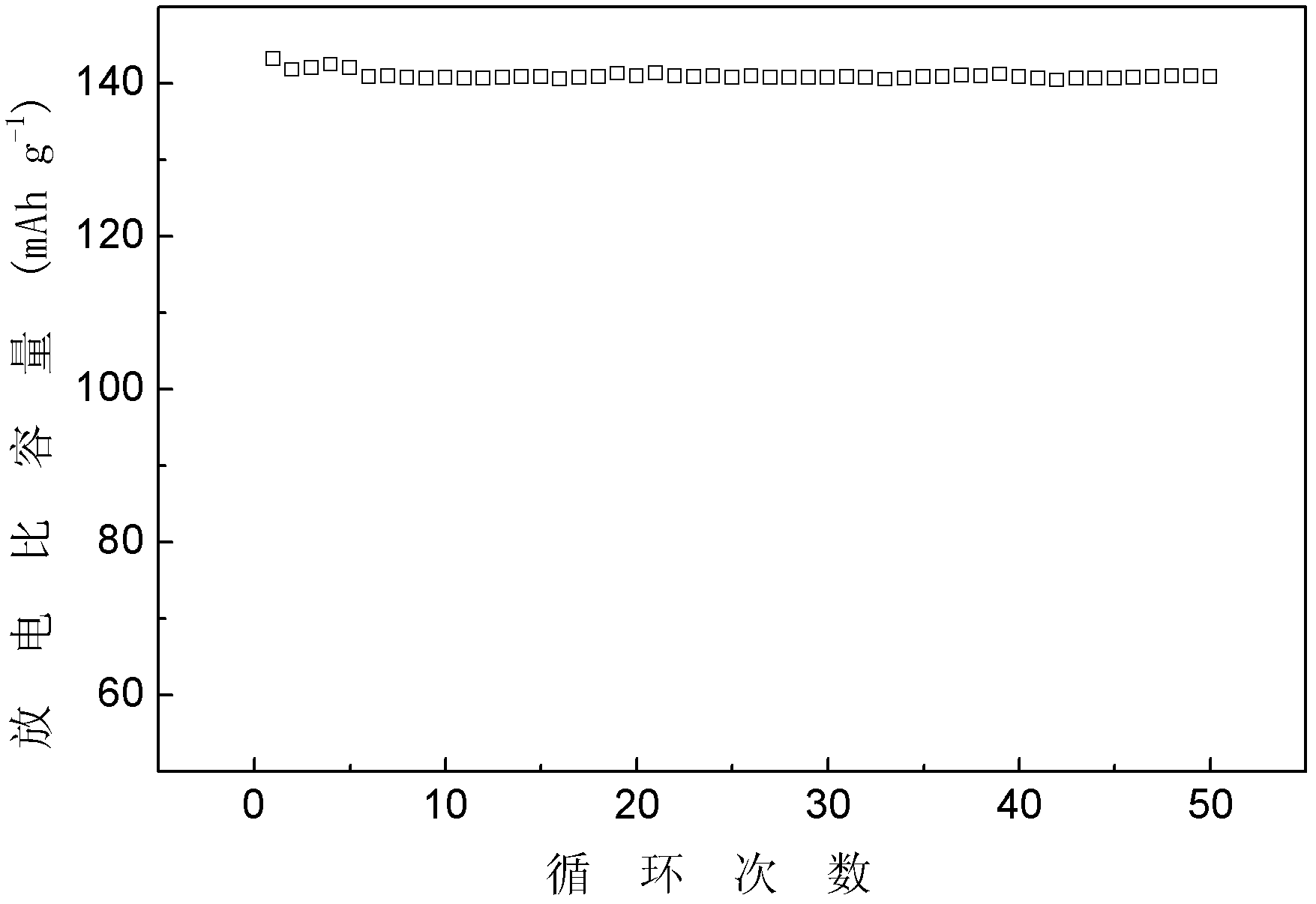

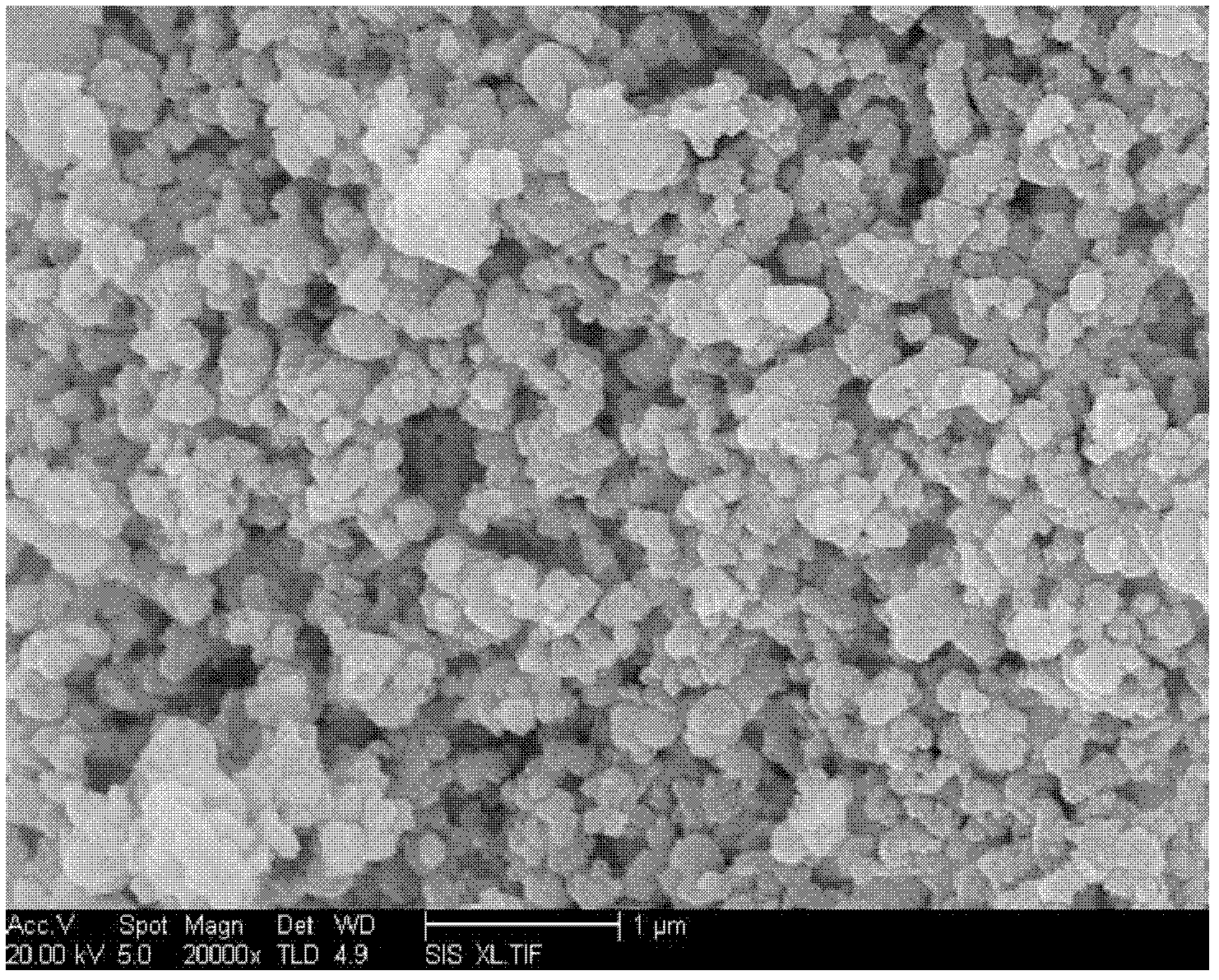

[0010] Li synthesized in this embodiment 4 Ti 5 O 12 The crystalline particles are uniform; charge and discharge tests show that the prepared Li 4 Ti 5 O 12 With higher initial discharge specific capacity and capacity...

specific Embodiment approach 2

[0011] Specific embodiment two: the difference between this embodiment and specific embodiment one is that the lithium salt described in step two is LiOH·H 2 O, LiF, Li 2 CO 3 、LiCH 3 COO·H 2 O and LiNO 3 one or a combination of several of them. Others are the same as in the first embodiment.

[0012] When the lithium salt described in this embodiment is a composition, the various components are in any ratio.

specific Embodiment approach 3

[0013] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the sintering atmosphere in Step 5 is air, ammonia decomposition gas, argon, nitrogen or hydrogen-argon mixed gas, wherein the hydrogen-argon mixed gas The mixing ratio of hydrogen and argon is arbitrary. Others are the same as those in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com