Production method for improving raw material utilization rate and glyphosate ammonium salt yield

A technology of glyphosate ammonium salt and production method is applied in the field of continuous production technology of glyphosate ammonium salt, which can solve the problem of insufficient utilization rate of raw materials, achieve mature reaction principle, realize efficient utilization rate, reaction speed and continuity good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

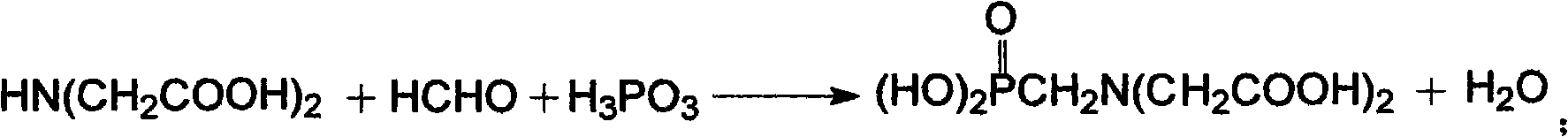

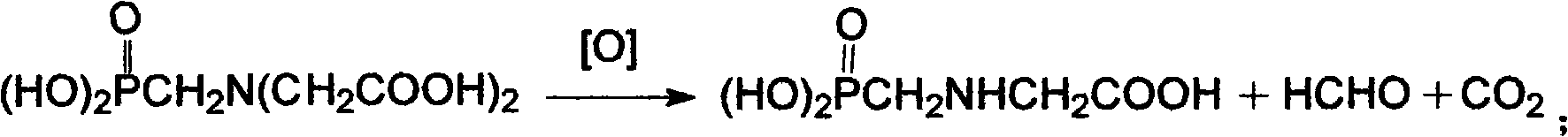

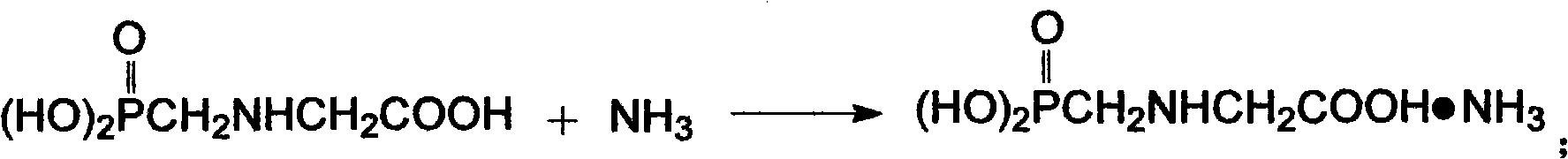

Method used

Image

Examples

Embodiment 1

[0041] The weight ratio of the glyphosate, water and the alcohol or aldehyde organic solvent is 1:0.8:3, and the alcohol or aldehyde organic solvent is methanol.

[0042] When the by-produced ammonia gas in step 1 is not enough for step 3, add ammonia gas separately; when the mother liquor of glyphosate ammonium salt obtained in step 5 is not enough for step 3, add glyphosate solid and water separately; and alcohol or water in step 5 When the aldehyde organic solvent is not enough for step four, additional methanol is supplied.

[0043] The crystallization and precipitation of the ammonium glyphosate salt is continuously performed in a cooling type crystallizer.

Embodiment 2

[0045] The weight ratio of the glyphosate, water and the alcohol or aldehyde organic solvent is 1:1:5, and the alcohol or aldehyde organic solvent is ethanol.

[0046] When the by-produced ammonia gas in step 1 is not enough for step 3, add ammonia gas separately; when the mother liquor of glyphosate ammonium salt obtained in step 5 is not enough for step 3, add glyphosate solid separately; and alcohols or aldehydes in step 5 When the organic solvent is not enough for step 4, additional ethanol is added.

[0047] The crystallization and precipitation of the ammonium glyphosate salt is continuously performed in a cooling type crystallizer. The 0.2%-2% glyphosate ammonium salt mother liquor obtained in the fifth step is not recycled, but is directly used to prepare a 35% glyphosate ammonium salt solution.

Embodiment 3

[0049] The weight ratio of the glyphosate, water and the alcohol or aldehyde organic solvent is 1:0.5:2, and the alcohol or aldehyde organic solvent is formaldehyde.

[0050] When the by-produced ammonia gas in step one is not enough for step three, additional ammonia gas is supplied; when the alcohol or aldehyde organic solvent in step five is not enough for step four, formaldehyde is additionally supplied.

[0051] The crystallization and precipitation of the ammonium glyphosate salt is continuously performed in a cooling type crystallizer. The 1%-2% glyphosate ammonium salt mother liquor obtained in the fifth step is directly used to prepare a 40% glyphosate ammonium salt solution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com