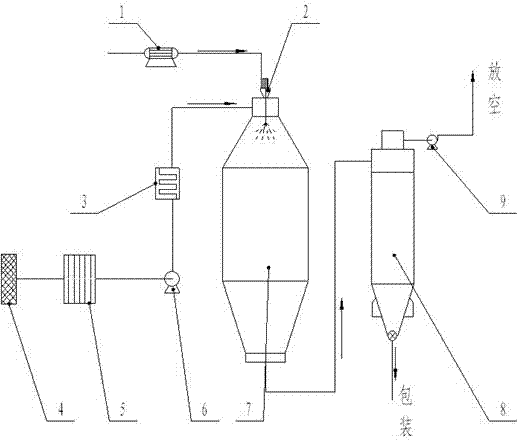

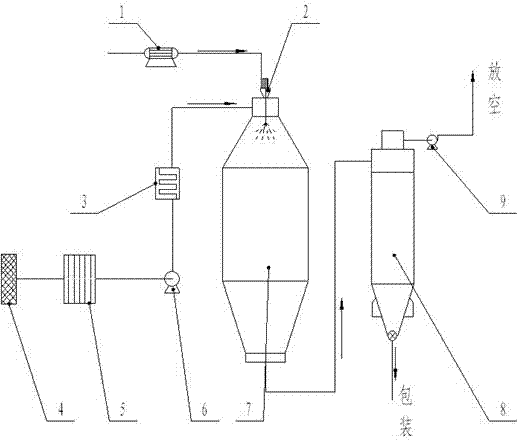

Atmospheric low temperature spray drying device and drying method

A drying device and drying method technology, applied in the direction of drying solid materials, drying, drying machine, etc., can solve problems such as complex process, achieve the effect of high efficiency, easy cleaning, and improve the ability to carry moisture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

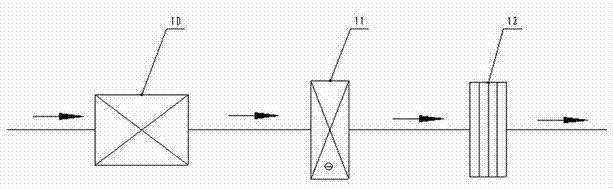

Method used

Image

Examples

Embodiment 1

[0028] The following data were obtained through experiments:

[0029] Atmospheric pressure and low temperature spray drying of sweet potato red pigment extracted from water,

[0030] Air inlet temperature: 60-80 ℃; air outlet temperature: 30-40 ℃; initial material temperature: 11-16 ℃;

[0031] The moisture content of the dried powder is 6-8%.

[0032] At a concentration of 1%, the measured color value of the stock solution is 5, and the color value after drying is 4.78.

example

[0033] Case study 2

[0034] Atmospheric pressure and low temperature spray drying of Ginkgo biloba flavonoids extracted from Ginkgo biloba leaves,

[0035] Air inlet temperature: 40-70 ℃; outlet air temperature: 30-40 ℃; initial material temperature: 11-16 ℃;

[0036] The moisture content of the dry powder is 5-8%.

[0037] The flavonoid content before drying was 25.7%, and the flavonoid content after drying was 24.1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com